DC ion bar efficiently solves the problem of electrostatic fire in coil production.

Case Background

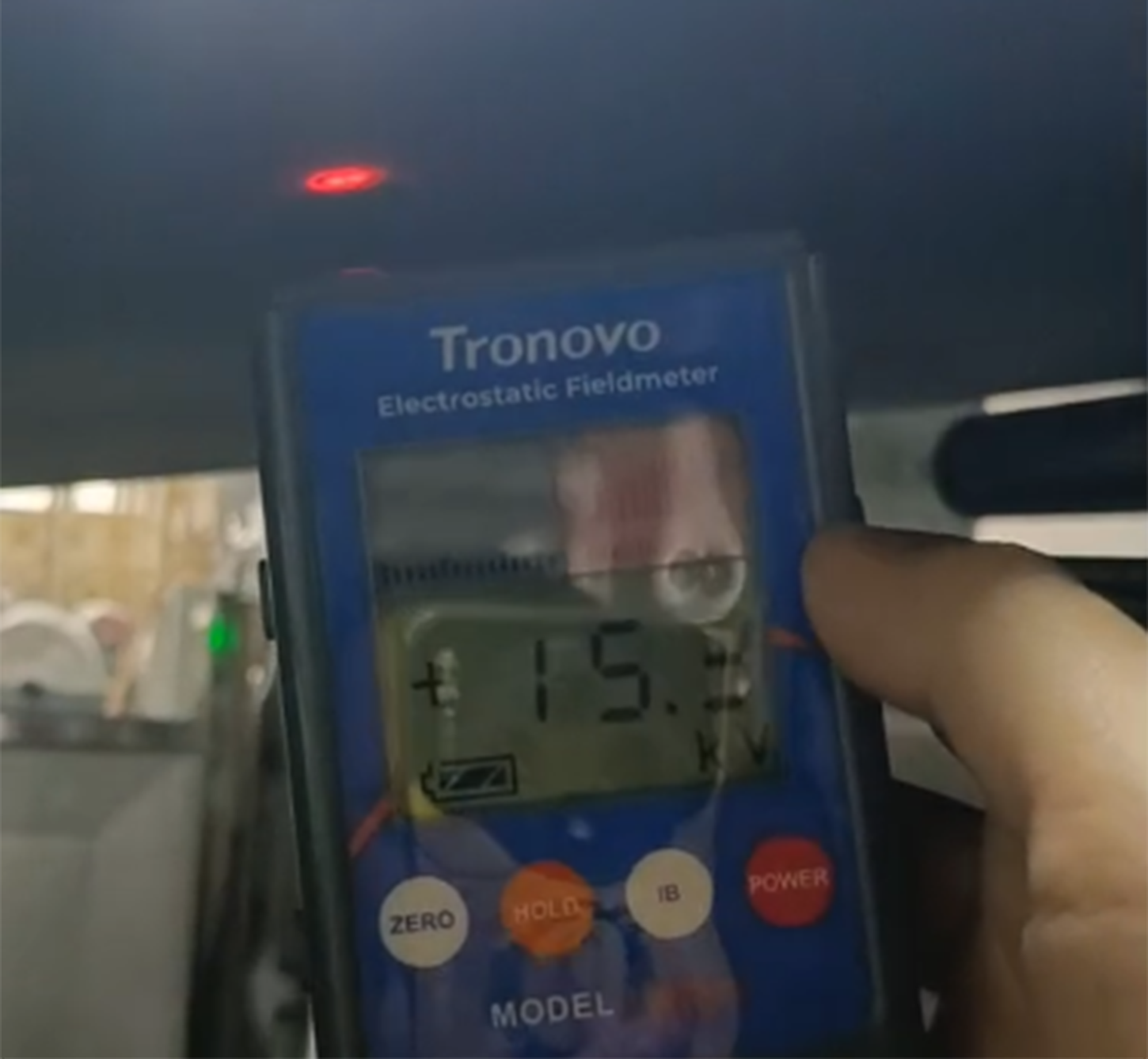

A large coil production enterprise has long been plagued by electrostatic problems in the production process. Before the coil enters the coating process, the electrostatic voltage is as high as 14kV, and frequent electrostatic discharge leads to multiple fire accidents in the production line, which not only affects the continuity of production, but also has major safety hazards. Enterprises have tried a variety of traditional static elimination methods, but the effect is not ideal.

problem analysis

The on-site inspection by the technical team of Tronovo found that the coil produced a large amount of electrostatic charge by friction with the equipment during high-speed operation, and the traditional AC ion bar had slow response speed and insufficient elimination capability, which could not meet the requirements of high electrostatic environment. Especially in the coating process, electrostatic discharge caused a number of fire accidents, a serious threat to production safety.

Solution

The technical team of Tronovo has launched a targeted pulsed DC ion bar (DC ion bar) solution:

Installation of EW DC-8000 Series DC Ion Bar Static Eliminator at Key Sites of Coil Transfer

Using patented DC pulse technology to achieve rapid response in milliseconds

Multi-point layout design to ensure the elimination of no dead ends

implementation effect

Breakthrough improvement was achieved after the installation of DC ion bar: the electrostatic voltage dropped from 14kV to 0.4kV, a drop of 97%; The electrostatic fire accident was completely eliminated, and the safety of the production line was significantly improved. At the same time, the production efficiency increased from 85% to 98%, and the product yield increased by 7.5 percentage points. The excellent performance of DC ion bar is highly evaluated by customers