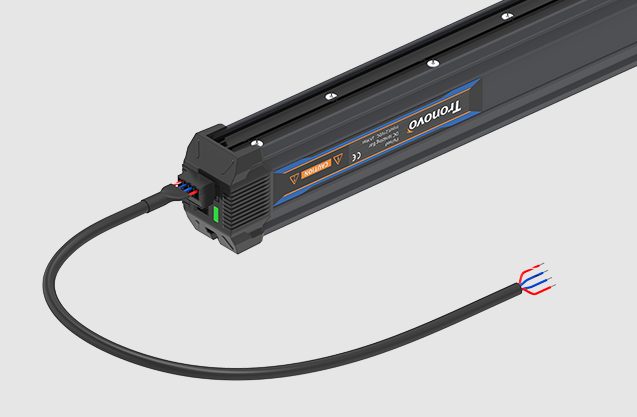

Adopting pure tungsten ion needles (life expectancy ≥30,000 hours) and integrated high-voltage module, it only needs 24V DC safety input to achieve rapid neutralisation of static electricity in 0.5 seconds. Equipped with DC pulse technology, the ion concentration is increased by 50%, which is suitable for high-speed production lines (≤800m/min) such as film rewinding and Li-ion manufacturing, and the IP66 protection and wide temperature design meets the harsh environment of semiconductor/chemical industry. Real-time monitoring of equipment through RS485/Modbus protocol, fault response efficiency increased by 90%. With localised cost (save 40% compared with imported), it integrates with Industry 4.0 intelligent management, helps enterprises to reduce cost and increase efficiency, and is the ideal solution for intelligent static elimination in the fields of precision electronics, automobile manufacturing and so on.

Product Features:

• New technology! Ultra High Performance. Adopting DC pulse technology, the ion concentration is increased by 50%, 0.5 seconds to quickly neutralise ±15kV static electricity, the performance is comparable to imported high-end models.

• 24V DC low voltage input. Safe power supply design, through the CE/UL dual certification, to eliminate the risk of high-voltage leakage, suitable for electronics, semiconductors and other highly sensitive scenes.

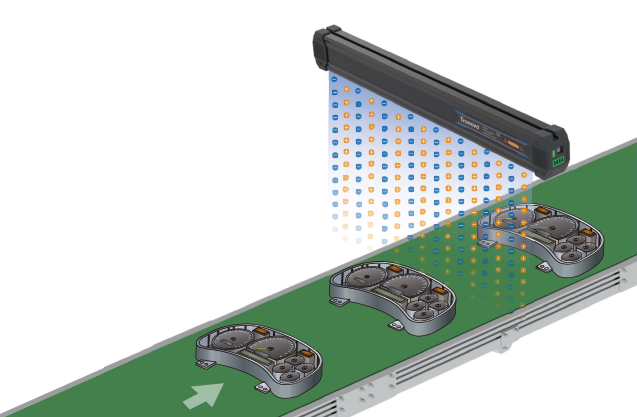

• 100% full coverage, no dead zone static elimination, effective length coverage of 1.5 metres, to meet the needs of film slitting, packaging and other wide production line.

• Ultra-long life, pure tungsten ion needle life ≥30,000 hours, epoxy resin sealed circuit, IP66 protection, -30℃~80℃ stable operation.