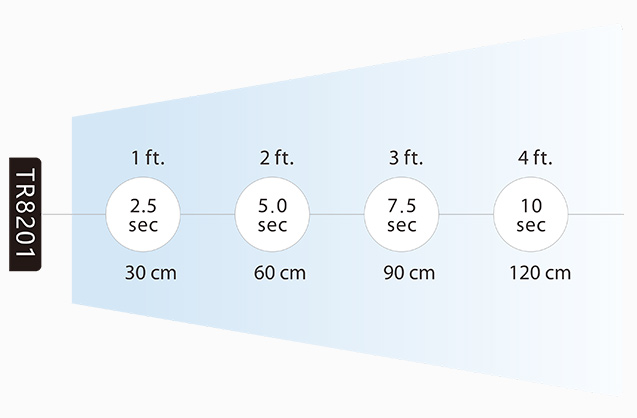

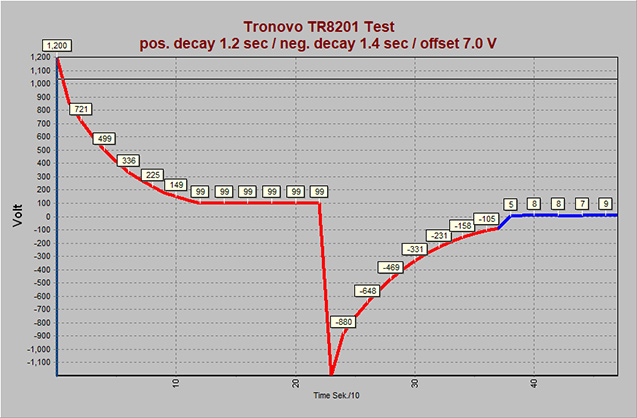

Using AC ionization technology, precise control of ion balance, 3 seconds to quickly neutralize the workbench static electricity, effectively prevent electronic components ESD damage and dust adsorption. Lightweight design, small size, flexible adaptation of desktop space, suitable for electronic manufacturing, semiconductor, laboratory and other ESD sensitive environment. Built-in ion needle cleaning system to reduce manual maintenance costs and extend equipment life. In line with ANSI/ESD S20.20 standard, the residual voltage is stable within ± 10V, providing reliable protection for precision production.

Features:

• Fast static elimination, dissipation time<3 seconds, ANSI/ESD S20.20

• Lightweight ion fan, compact design optimized for electrostatic protection of the work table

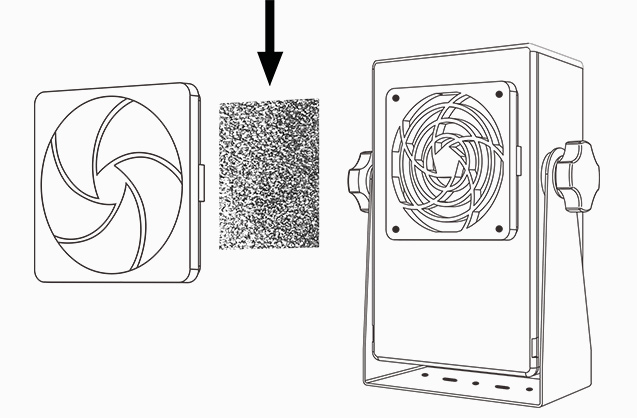

• Equipped with cleaning brush, easy maintenance of ion needle, prolong the service life of equipment

• Wind speed can be adjusted to meet the needs of different scenarios of electronic assembly/laboratory

• Silent, low-noise design, ISO occupational health standards

• CE certification, industrial anti-static equipment quality assurance