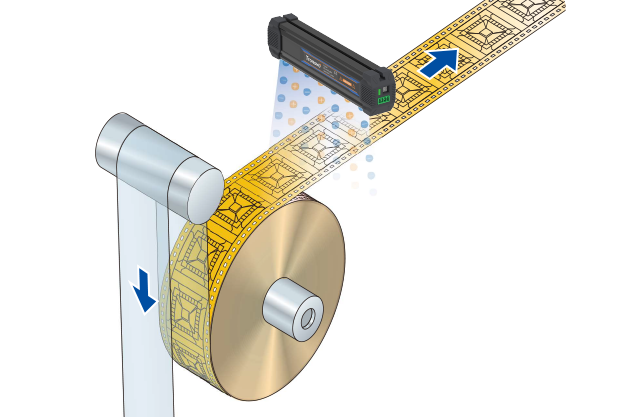

Adopting DC high-voltage pulse technology, it realizes wide-area ion coverage by intelligently switching between positive and negative electric fields, and the vertical dissipation range is 50% larger than that of traditional DC technology. Innovative independent electrode needle design with pulse modulation, precise control of ion frequency and intensity, electrostatic neutralization efficiency increased by 60% while reducing electrode loss. No external air source is required, especially suitable for clean room electrostatic elimination needs!

Product Features

• Pulse DC ion bar, higher utilization rate of ion generation, more efficient static elimination.

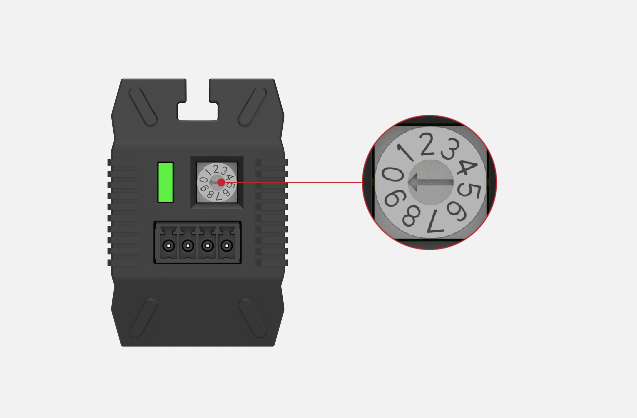

• Support IO control, RS485 communication, real-time abnormal alarm signal output.

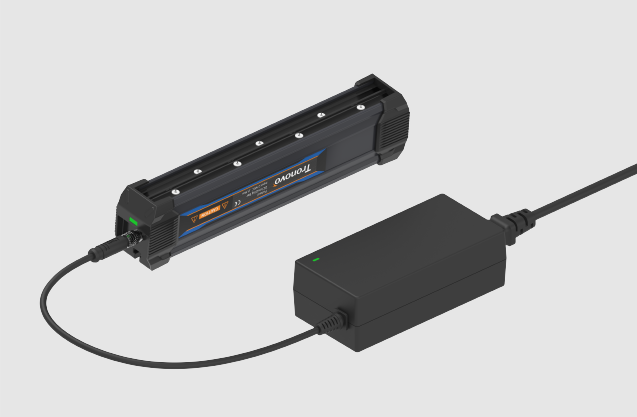

• 24V DC power supply, safe and stable, compatible with industrial standards.

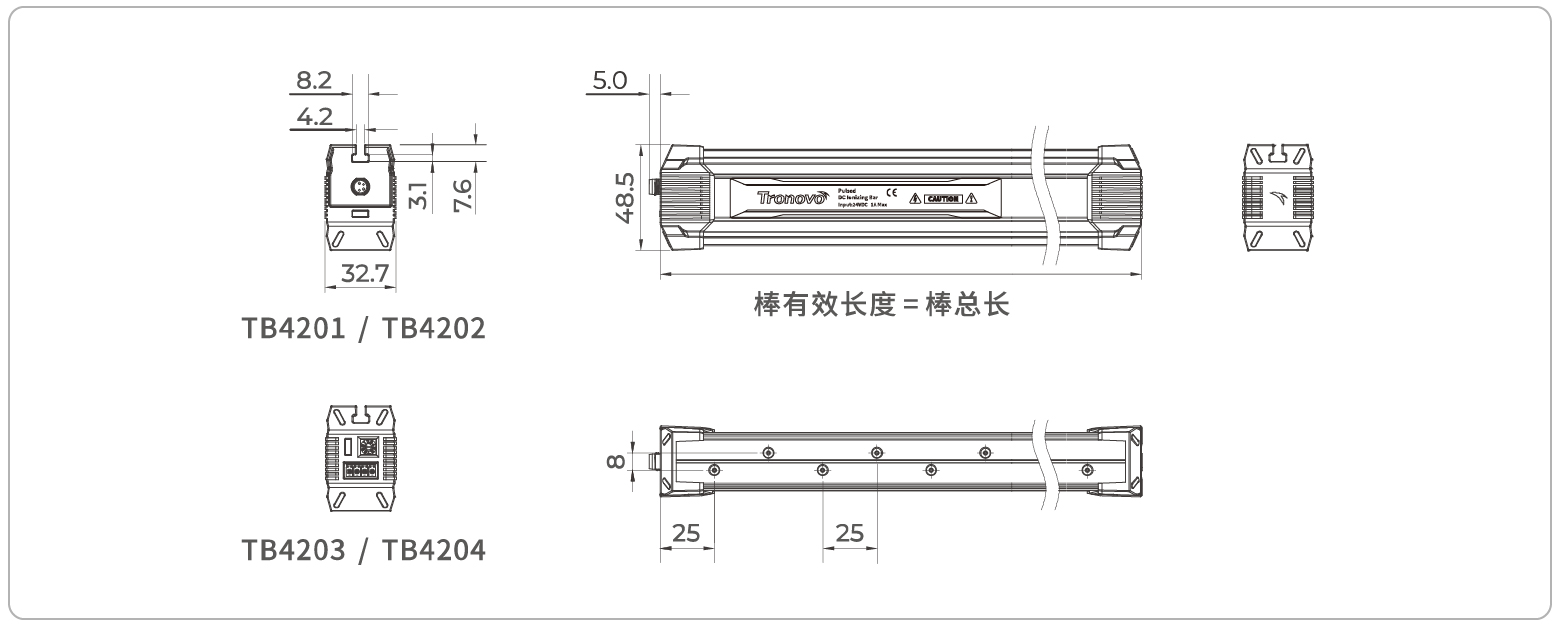

• Ion needle spacing 25mm, optimize the layout to enhance the efficiency of neutralization.

• No air source design, especially suitable for clean room applications.