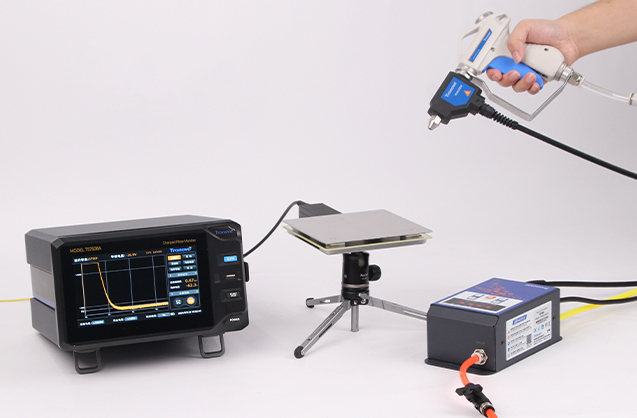

Ion air gun - professional solution for handheld static elimination and dust removal! Adopting the perfect combination of ion nozzle technology and compressed air gun, it efficiently cleans complex surfaces such as profiles, plastic sheets, car bodies, electronic assemblies, etc., and solves the problem of electrostatic adsorption of dust. Suitable for paint spray booths, plastic packaging, container cleaning and other fields, quickly neutralise static electricity and blow away stubborn dust to improve production efficiency. Equipped with a spring hook balancer, the operation is more convenient and labour-saving. The lightweight design is ergonomic and supports long-time use, making it an ideal tool for industrial dust removal and static control!

Translated with DeepL.com (free version)

Product Features:

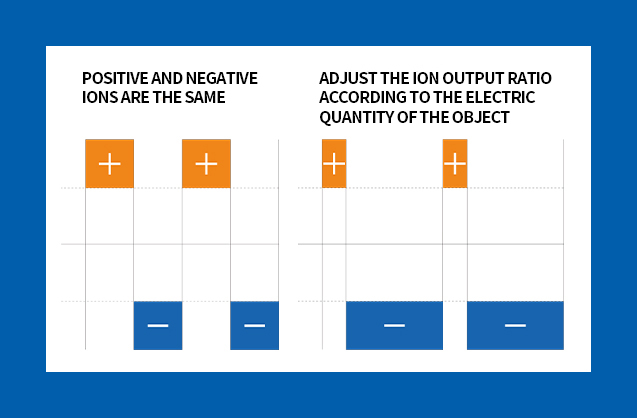

•Pulse AC controller, adjustable ion balance and frequency.

•Efficient de-static dust removal, quickly remove surface contaminants.

•Powerful ionic airflow, powerful blowing force, concentrated airflow and precise cleaning.

•Ergonomic design, the grip part fits the curve of the hand.

•Safe and reliable, with multiple protection functions to ensure the safety of the operator.

•High durability, using high-quality materials and precision manufacturing process, anti-wear, anti-corrosion.

•AC pulse technology reduces electrode loss, prolongs service life and reduces maintenance costs.