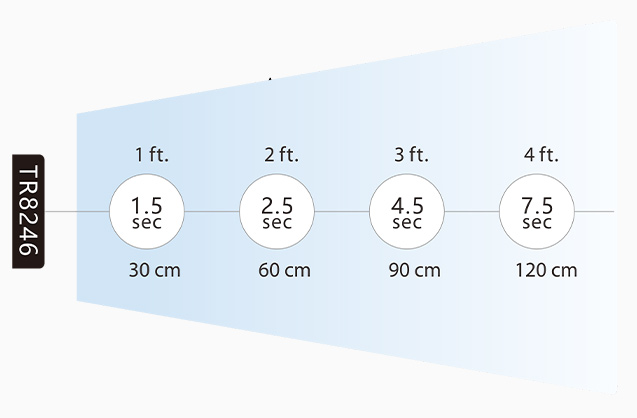

The closed-loop control circuit system is adopted to ensure that the static elimination speed is less than or equal to 2 seconds (30cm distance), covering an ultra-wide range of 1200mm, meeting the needs of high-precision industries such as electronics, semiconductors and medical treatment. Double high-pressure release technology to enhance stability, adapt to changes in temperature and humidity, with stepless speed fan, precise control of wind. The modular design supports automatic cleaning of titanium needles, prolonging life and reducing maintenance costs. Economical and efficient, through CE certification, is the production line, dust-free workshop and ESD protection area of the ideal electrostatic removal equipment.

Features:

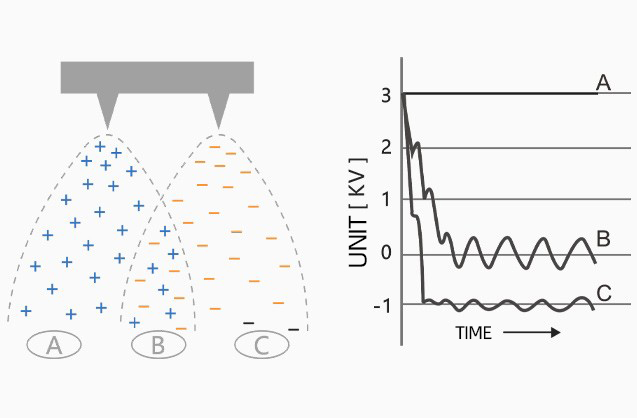

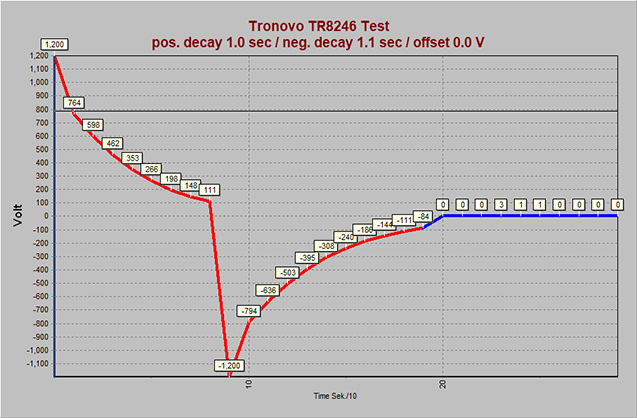

• Steady-state DC ionization technology, rapid elimination of static electricity, electrostatic dissipation time ≤ 2.5 seconds (30cm test distance), accurate and efficient

• Desktop-level static elimination, directly for the work area, suitable for electronic assembly, SMT patch, laboratory and other scenarios

• stepless speed control fan, strong wind adjustable, meet the needs of ESD protection

• Calibratable ion balance (within ± 15V) to ensure no static residual and protect sensitive components

• Automatic cleaning of ion needles, reduce maintenance, extend equipment life, suitable for dust-free workshops, semiconductor packaging