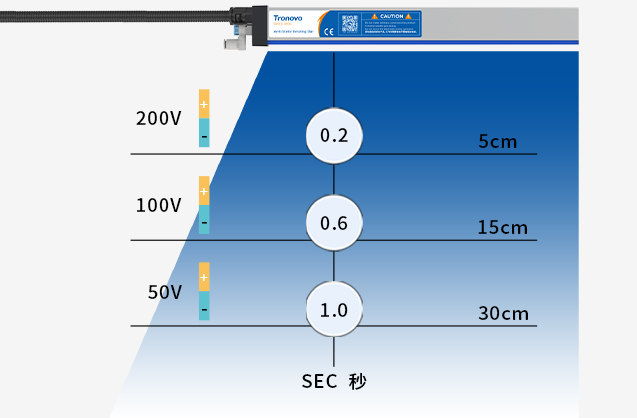

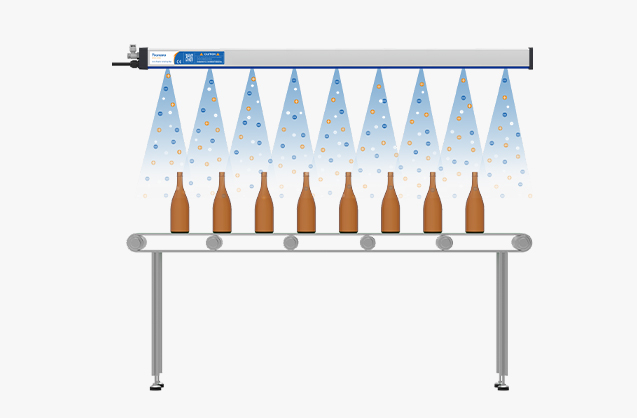

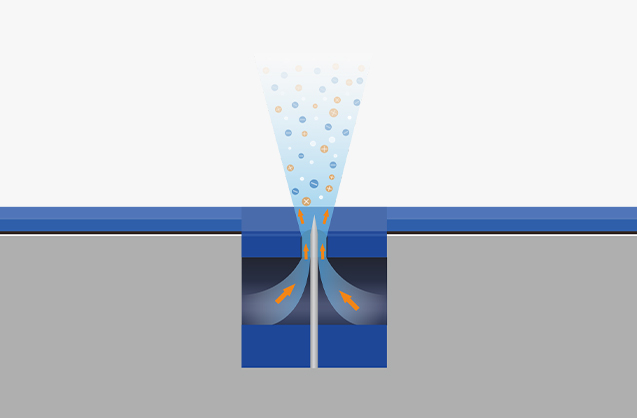

This cost-effective static elimination wand adopts an innovative structural design, placing the ion needle precisely in the centre of the air outlet to form a wrap-around airflow barrier, effectively preventing foreign matter from contaminating the tip of the ion needle and reducing maintenance costs by more than 50%. It is equipped with pure tungsten emitter needle and high voltage generator, 0.3 seconds to quickly neutralise static electricity, de-static speed 2-3 times faster than traditional products. Through the resistive coupling design to achieve 99% safe operation without electric shock. Has been successfully applied to film, printing, plastic, spraying, textile and other industries. Convenient installation and easy to use. Ideal solution to improve production efficiency and yield rate in electronics, packaging, medical and other fields.

Features:

• Air barrier design, innovative maintenance-saving structure, air isolation technology effectively prevents foreign objects from approaching the ionic needle, reducing contamination

•Resistive coupling technology, 0 electric shock safety protection, to ensure 100% safety of the operator

•Super ionisation performance, support high speed coil production, increase production efficiency by 30%.

•Patented connection technology, airtight high-voltage plug + flexible coaxial shielded cable, anti-interference, wear-resistant, more stable signal transmission

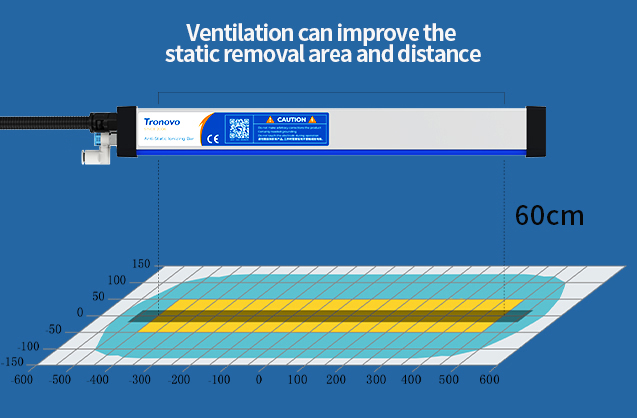

•Long distance static elimination, 30cm long range of action, suitable for large equipment and wide material processing needs.

•Safe and environmentally friendly materials, easy to wipe the aluminium alloy + flame retardant PVC housing

•Convenient installation system, back bar slot design, support bolt flexible adjustment, 10 seconds to complete the installation, compatible with all kinds of production lines.