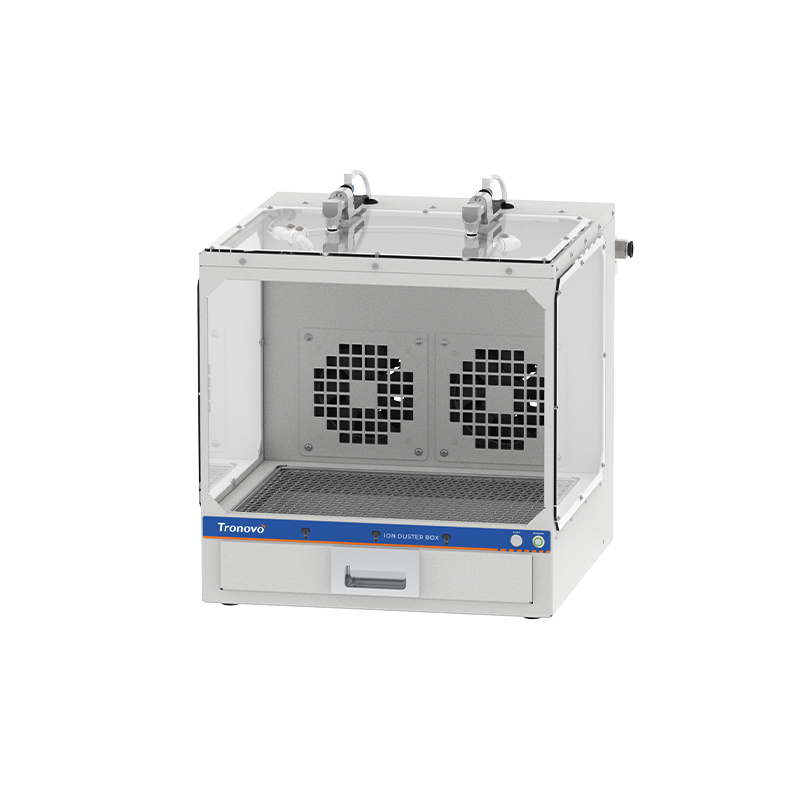

Designed for precision workpieces such as electronic components, lenses, smart phones, lampshades, cosmetic boxes, home appliance components, etc., it integrates electrostatic elimination + efficient dust removal + dust collection, and completely solves the problem of electrostatic accumulation and dust residue. Using independent ion blowing + air blowing dual system, the efficiency of electrostatic dust removal is increased by 50%, effectively preventing dust from adhering to the second time.

Product Features:

• Built-in air curtain isolation system, efficient blocking of secondary pollution

• High-precision photoelectric sensor, light curtain induction zero blind area

• Multiple mode switching, one key to adapt to different working conditions

• Industrial grade IO interface, support PLC/robot automation interlock control

• Quick-release dust box for quick maintenance