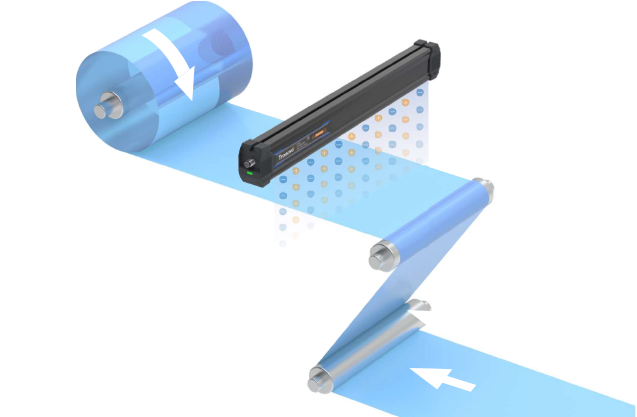

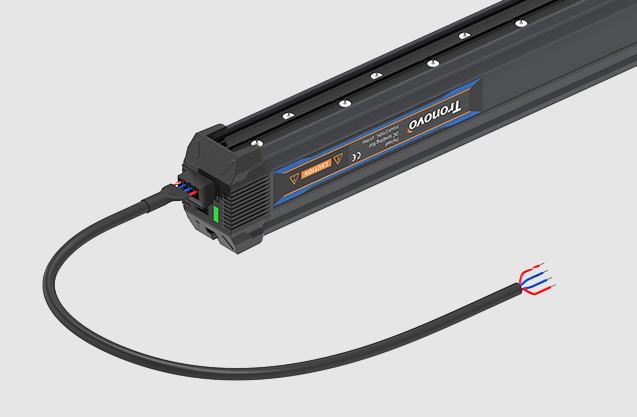

Adopting pulse DC technology, through independent positive and negative electrode needles alternately release high-voltage pulse electric field, eliminating electricity efficiency is more than 200% higher than the traditional AC technology. Airless design, 5cm ultra-thin body can be embedded in the production line slit, support windless silent de-static, avoid airflow interference, suitable for clean room and high-speed coil scene (600m/min). Intelligent control system through the three-colour LED status lights (running/alarm/fault) and PLC/RS485 communication interface for real-time monitoring and control, accurately adapted to the needs of the production line. Suitable for printing (solving ink splash, colour registration inaccuracy), film slitting (eliminating hundreds of thousands of volts of static electricity) and other high-precision fields, to extend the life of the electrodes and reduce maintenance costs.

Product Features

• Adopting pulse DC technology, the ion generating efficiency is increased by 50%, and the static electricity is neutralised faster.

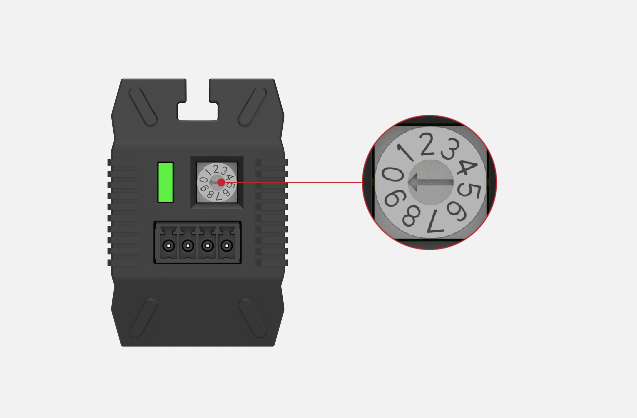

• Multi-level frequency adjustable, intelligent matching 25-150mm working distance.

• Support IO control, RS485 communication, real-time output of abnormal alarm signals, seamless connection to automated production lines.

• 24V DC power supply, low power consumption design, suitable for industrial equipment standard voltage.

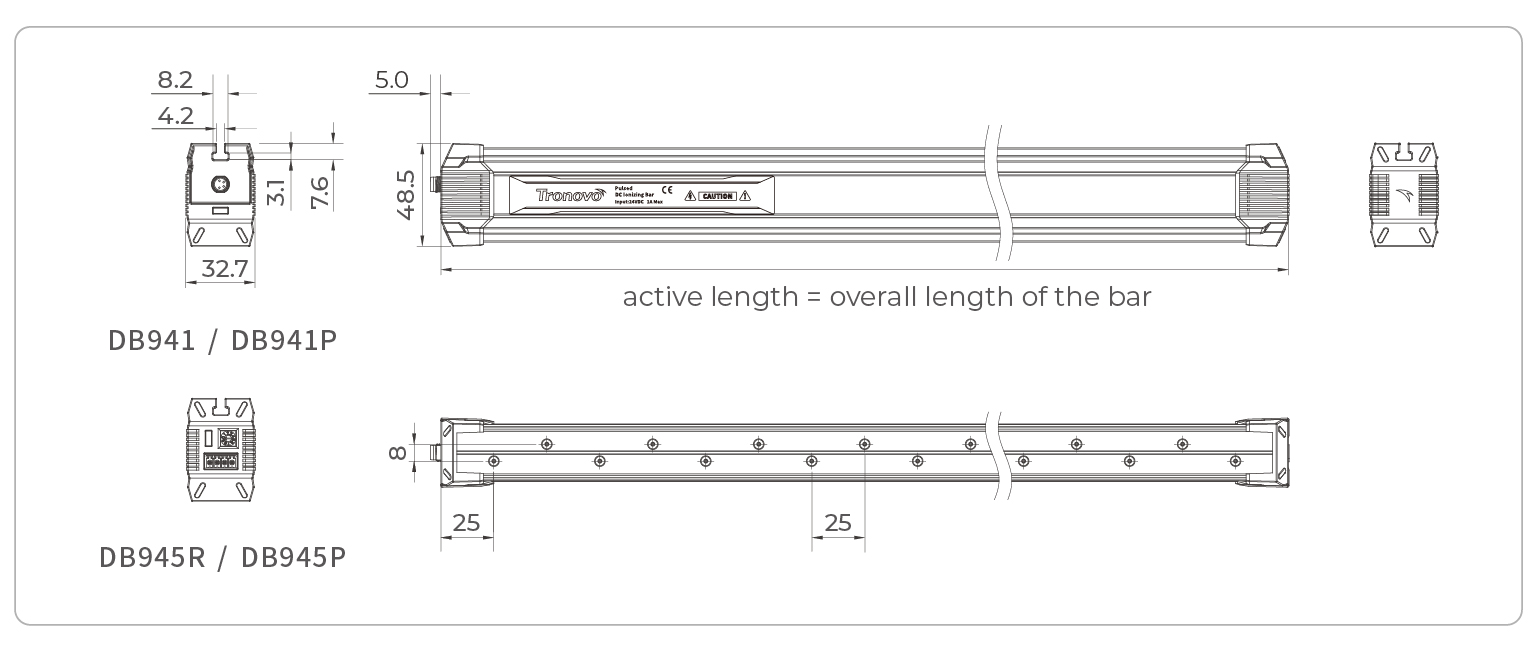

• High-efficiency power dissipation range of 25-150mm, ion needle spacing of 25mm, accurate coverage of the target area.

• Airless design, suitable for clean room, electronic manufacturing, printing and packaging and other scenes.