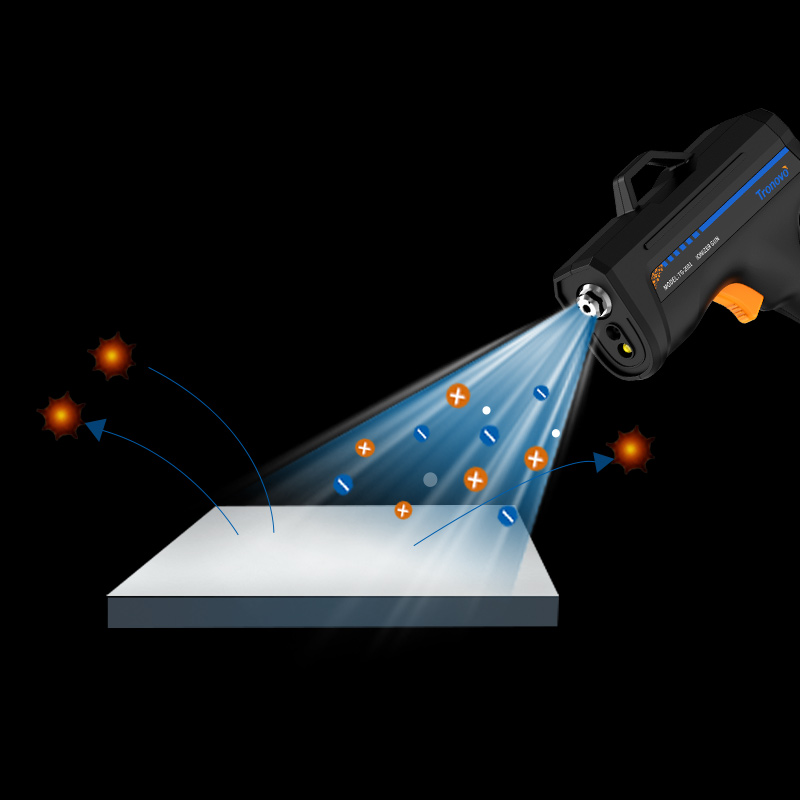

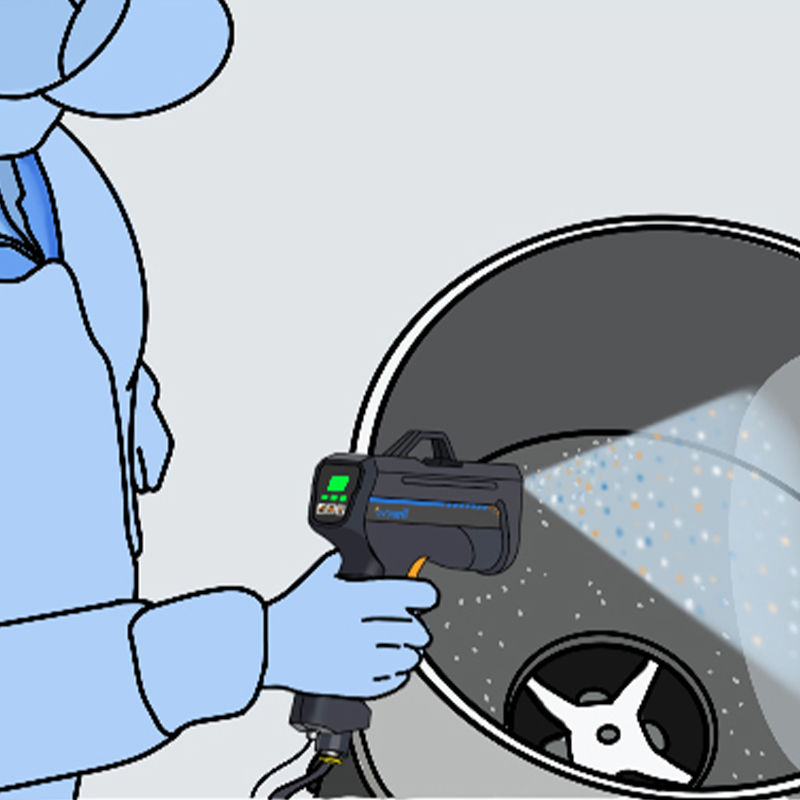

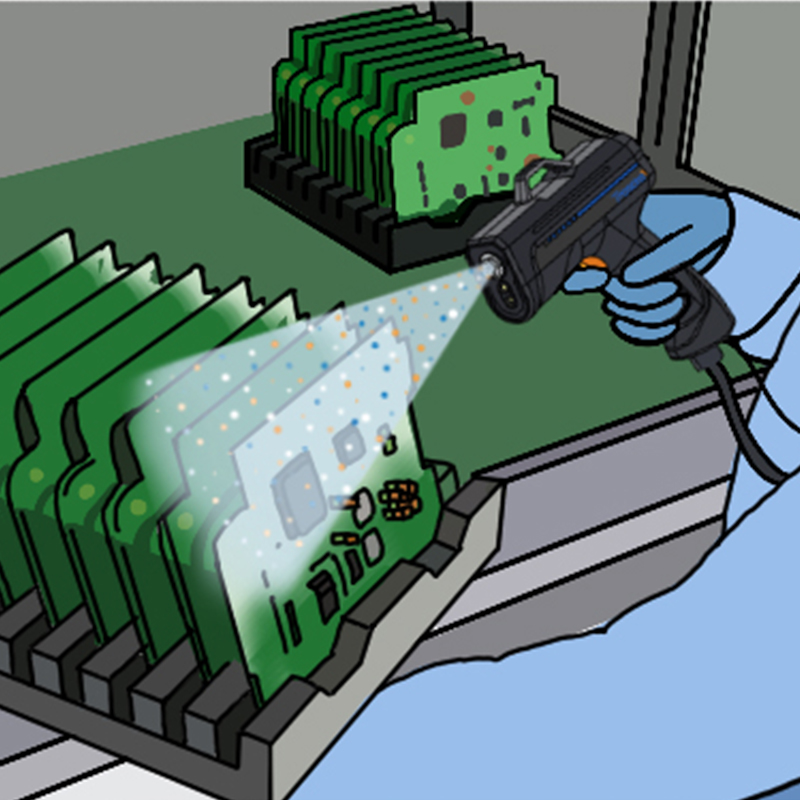

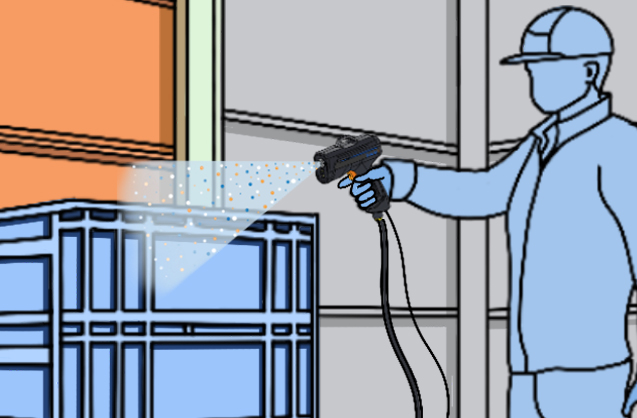

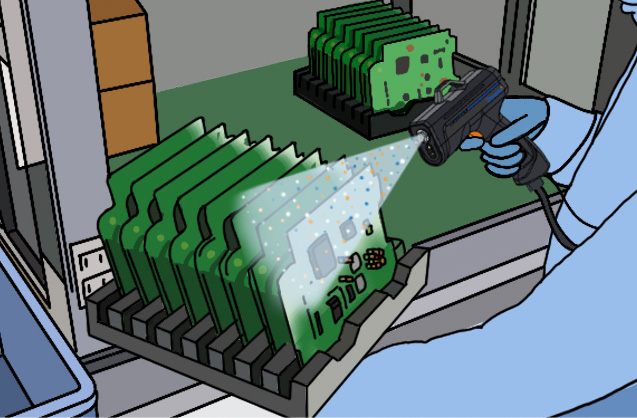

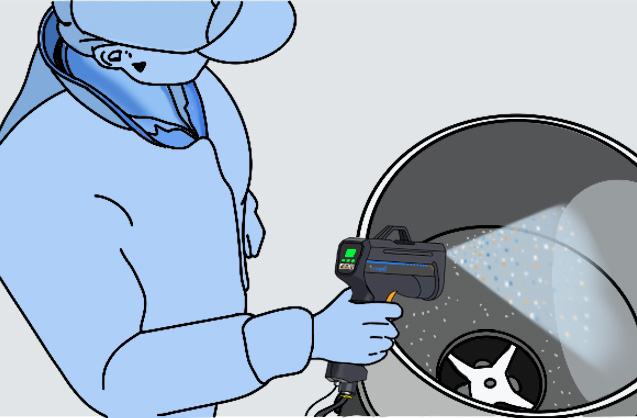

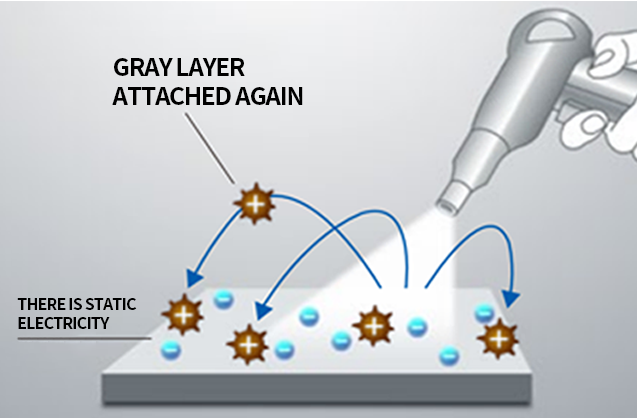

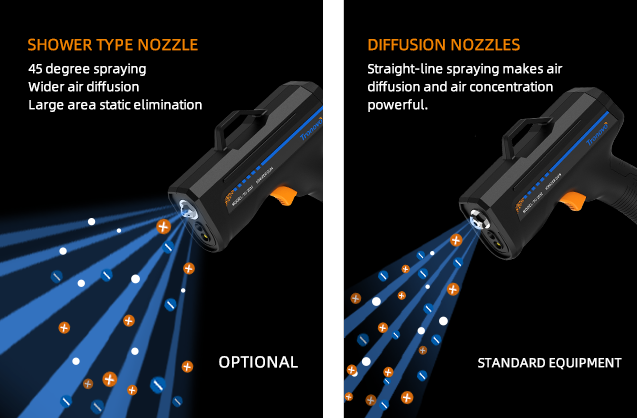

Adopting high-frequency AC control technology, with low air resistance structure design, greatly reducing the air pressure loss, to achieve high efficiency dust removal and strong adsorption effect. Built-in solenoid valve controller integrated structure, eliminating the need for external controller settings and complex high-voltage wiring, convenient operation and safe and stable. Real-time monitoring of the status of the equipment through the indicator light, maintenance is more intuitive. Suitable for industrial cleaning, precision instrument dust removal and other scenes, to enhance the life of the equipment and the cleanliness of the production environment.

Features:

• Powerful dust removal capability, efficiently removes stubborn dust.

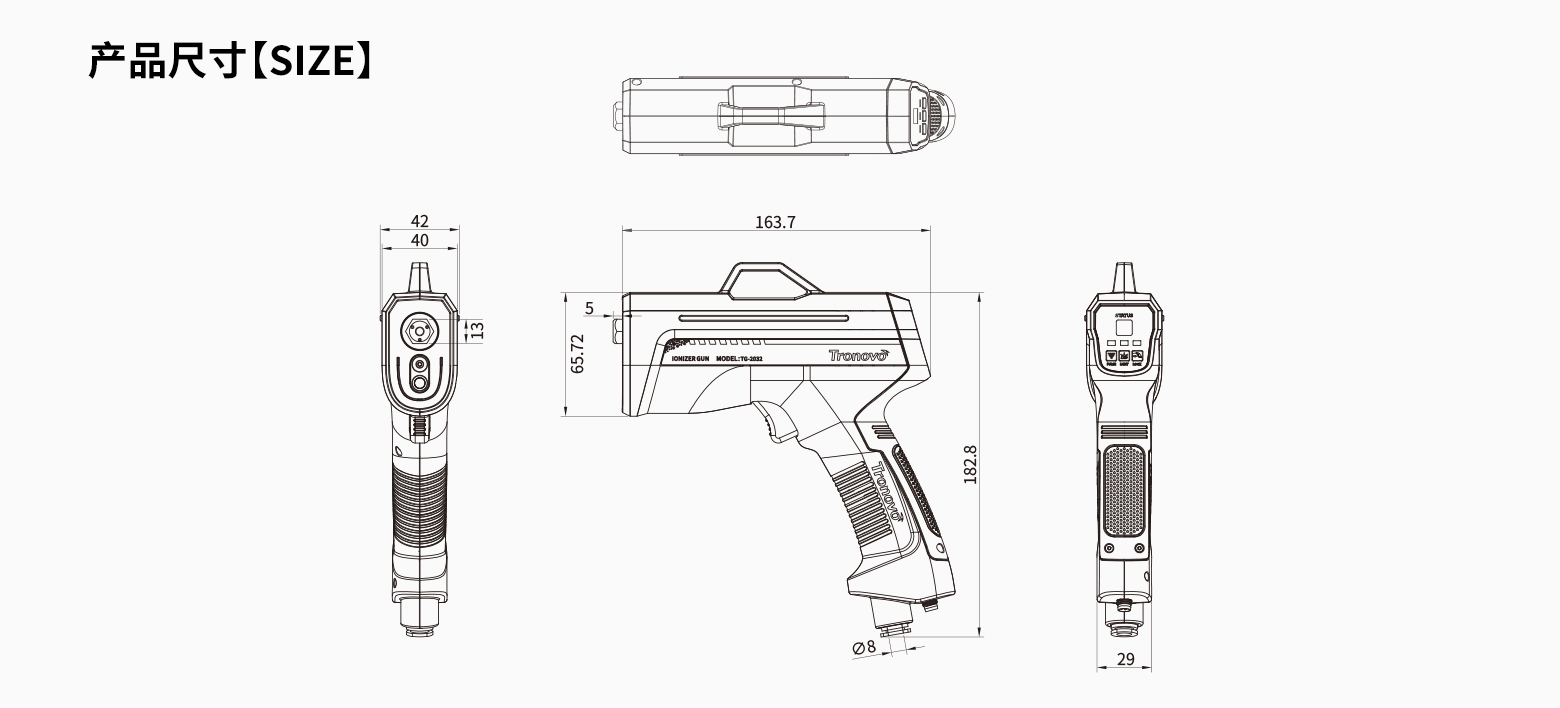

• Ergonomic design, ultra-comfortable hand feeling, long-lasting operation without fatigue.

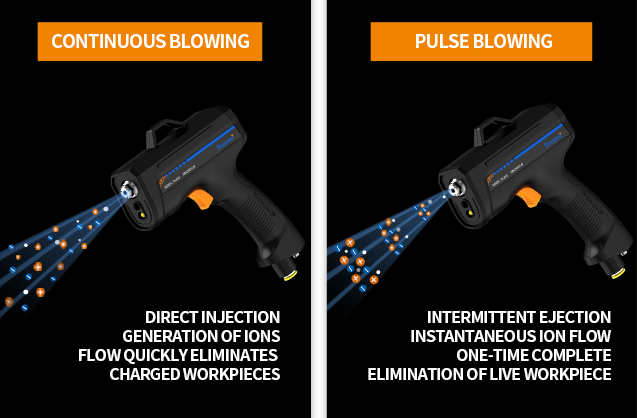

• Two blowing modes (continuous/pulse) to cope with different cleaning scenarios.

• Infrared laser precise focus, lock the dust without missing.

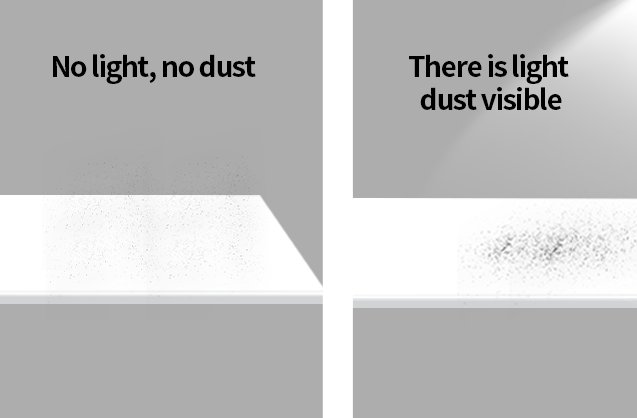

• High-brightness dust detection light, dark stains at a glance.

• Pulse airflow technology, intermittent impact to improve dust removal efficiency.