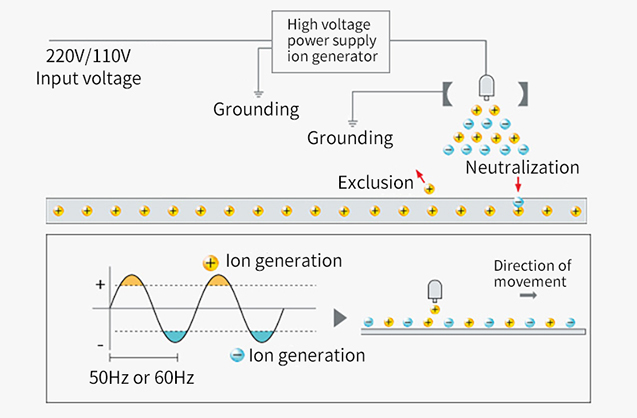

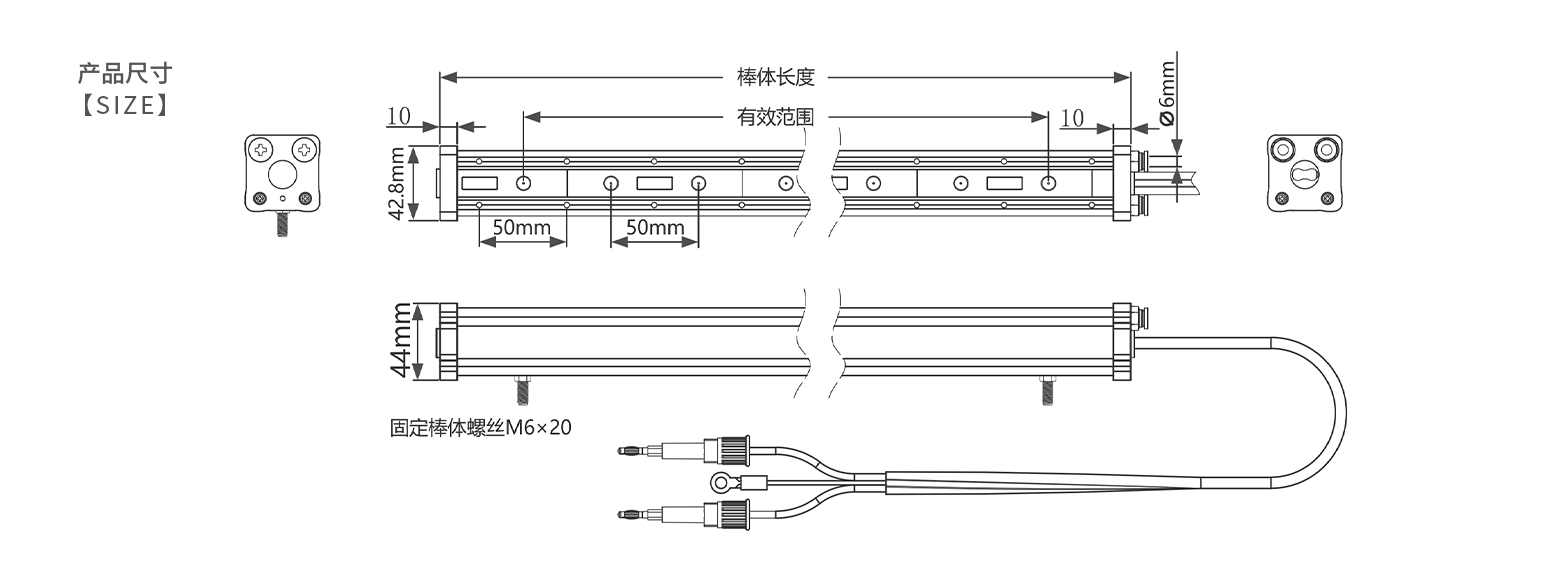

With its new ionization technology, the ion rod has set a new standard in the industry, and its performance meets the strict requirements of the electronics industry for the residual voltage of the ionizer in the EPA electrostatic discharge protection zone to be less than ±35V, the aluminum alloy shell is suitable for use in clean rooms due to its oxidation resistance and low particle emissions, and the light contour of the aluminum color ensures a good visual integration of the clean room.

Features:

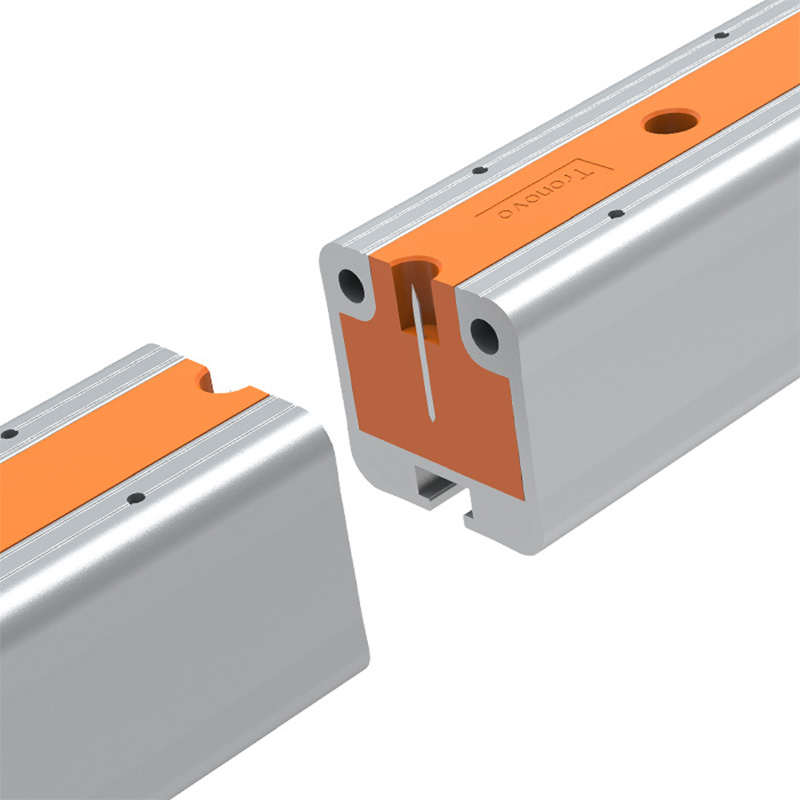

• Excellent stability, electric and pneumatic separation design

• Inductive coupling technology to ensure operator safety

• Excellent ion balance, in line with electronic industry standards, below ±35V

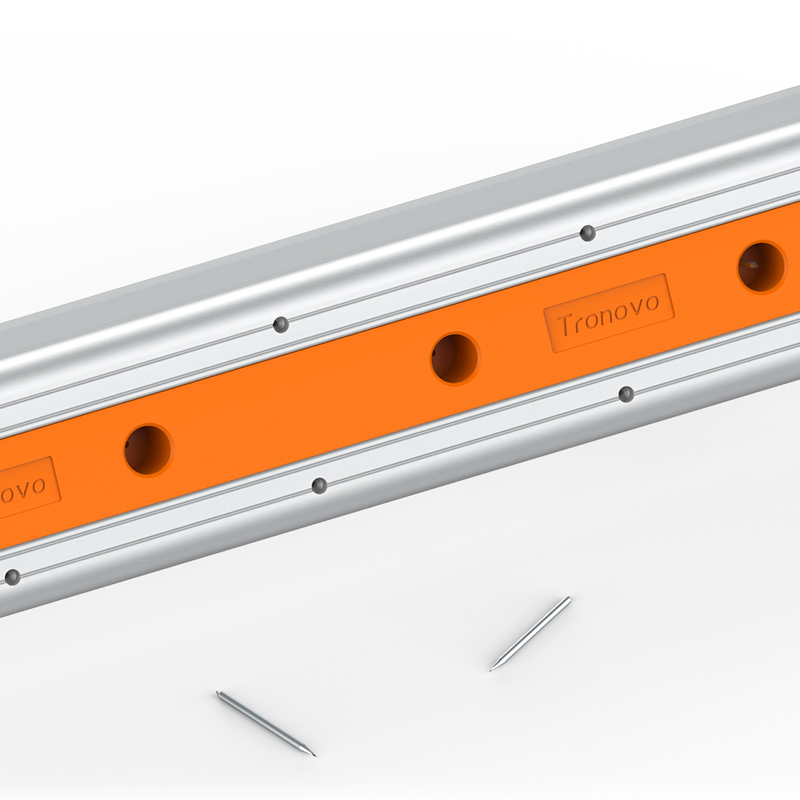

• Low Emissions - Suitable for clean rooms, maintaining the cleanliness of clean rooms

• The design of two rows of air vents improves the coverage area of ionic air

• Use flame retardant PVC environmental protection material

• Easy to install-with angle adjustment bracket