Adopting 70,000Hz high-frequency AC technology, the static eliminator achieves efficient synergistic release of positive and negative ions through high-frequency AC electric field, which significantly improves the speed and stability of static electricity neutralisation. Compared with traditional low-frequency or DC methods, high-frequency AC technology can maintain an ultra-low ionic balance offset of ±10V under high ion concentration environments, and can cover a wider range of static elimination without frequent adjustment of installation distance.

Features:

•High-frequency AC electrostatic elimination technology, ±10V within the ultra-precise ion balance, to meet the semiconductor-level electrostatic control needs.

•Intelligent digital display, real-time monitoring of wind speed, support for adjusting the work mode

•Full-automatic ion needle cleaning system (1-99 hours cycle can be set), reduce 90% of the tip of the oxidation loss, extend the life of 3 times

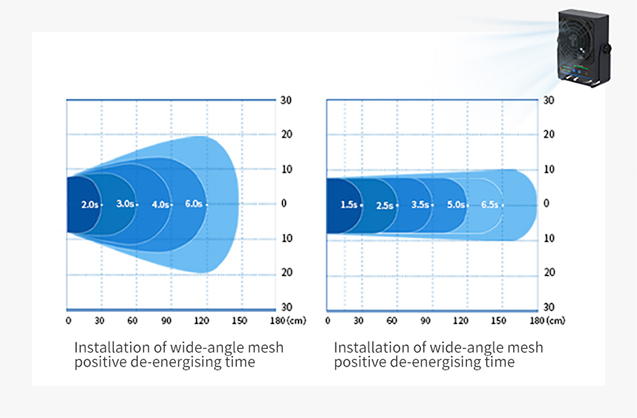

•Wide-area airflow optimisation technology, covering 50cm~3m de-static range, turbo fan wind speed increased by 40% to 8m/s.

•Intelligent alarm system

•Double safety interlock mechanism, open the lid 0.1 seconds to cut off the high-voltage power supply

•Industrial-grade communication protocol, standard IO control + RS485 interface, optional Ethernet/WiFi remote monitoring.