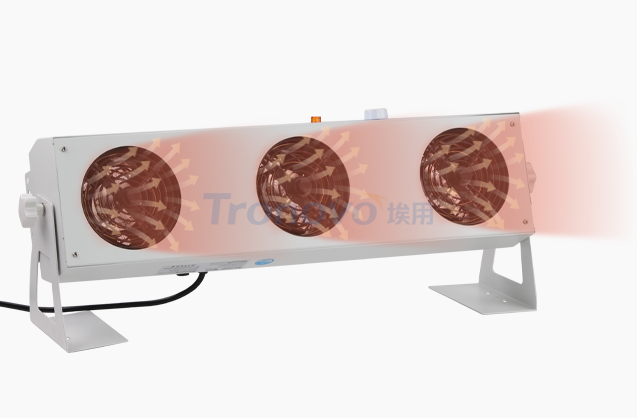

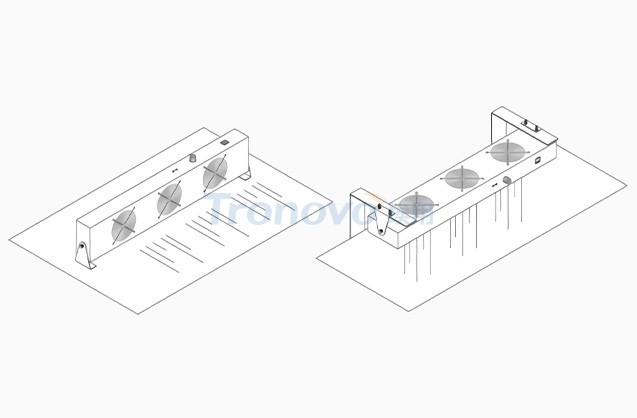

Hanging Ion Blower - The ideal solution for efficiently eliminating static pollution! Designed for electronic assembly lines, pharmaceutical manufacturing, printing and packaging and other precision industries, it can quickly neutralise the static charge in areas that are not easily accessible and prevent static damage. Stable ionic balance, suitable for clean workshop. Built-in high voltage generator and speed switch, adjustable air volume, suitable for maintenance stations, air shower equipment and other scenes. Stainless steel shell is durable and dustproof, equipped with ion emitter cleaner, convenient maintenance. Hanging installation, saving space while improving the efficiency of electrostatic protection, is the necessary equipment for semiconductor, liquid crystal components and other industries!

Features:

• Large coverage of static elimination, rapid neutralisation of static charges on the workbench, suitable for electronic assembly lines, SMT workshop and other scenes.

• Built-in cleaning brush, easy maintenance, extend the life of the ion fan.

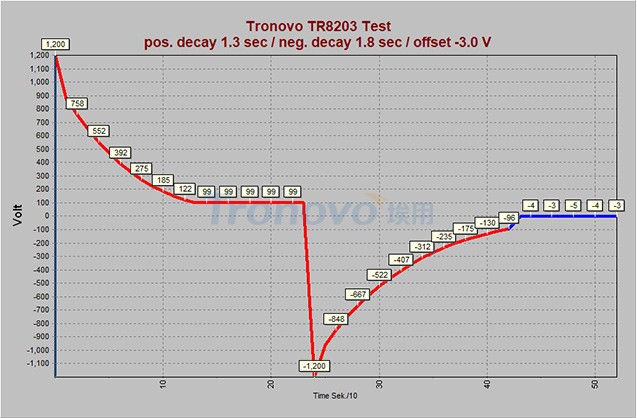

• ±15V ion balance to ensure stable electrostatic protection effect

• Dual filtration system, optional air inlet filter, effectively blocking dust / particles, in line with clean room standards

• Infinitely adjustable fan with strong wind power, suitable for semiconductor and LCD production.