Capsule, pharmaceutical packaging line static electricity elimination case

In capsule and pharmaceutical packaging lines, static eliminators can play an important role in helping to remove static charges and preventing the effects of static electricity on pharmaceutical packaging and production lines.

Static electricity can cause the following problems in capsule and pharmaceutical packaging:

Adsorption: Static charges can cause capsules or packaging materials to have the same or opposite charges on their surfaces, causing them to attract each other. This may result in capsules being difficult to separate or packaging materials being difficult to unfold, affecting productivity.

Adhesion: Static charges may cause dust, debris, and other substances on the capsule or packaging material to carry an electrical charge, causing them to adhere to the capsule surface or packaging material. This may affect product quality and appearance.

Electrostatic Discharge: Static charges accumulated on the capsule or packaging material may result in an electrostatic discharge, generating sparks. This is a safety hazard for pharmaceutical packaging lines, as static discharges can cause fires or explosions.

Static eliminators can eliminate these static problems by releasing ions. The ions will interact with the static charge on the surface of the capsule or packaging material to neutralize or cancel out the static charge. This reduces static adsorption and adhesion and prevents static discharges from occurring.

Installing static eliminators on capsule and pharmaceutical packaging lines can help improve productivity, ensure product quality, and ensure a safe working environment. They are often placed in locations where static electricity is most likely to build up, such as near equipment such as capsule separators, packaging machinery, etc., to minimize static electricity problems.

The Problem:

Thermal vacuum molding generates static electricity, resulting in blisters with very high static electricity. Packaging operations will occur: blister off the set, personnel electric shock, blister dust absorption, product jump off the blister and other phenomena.

Solution:

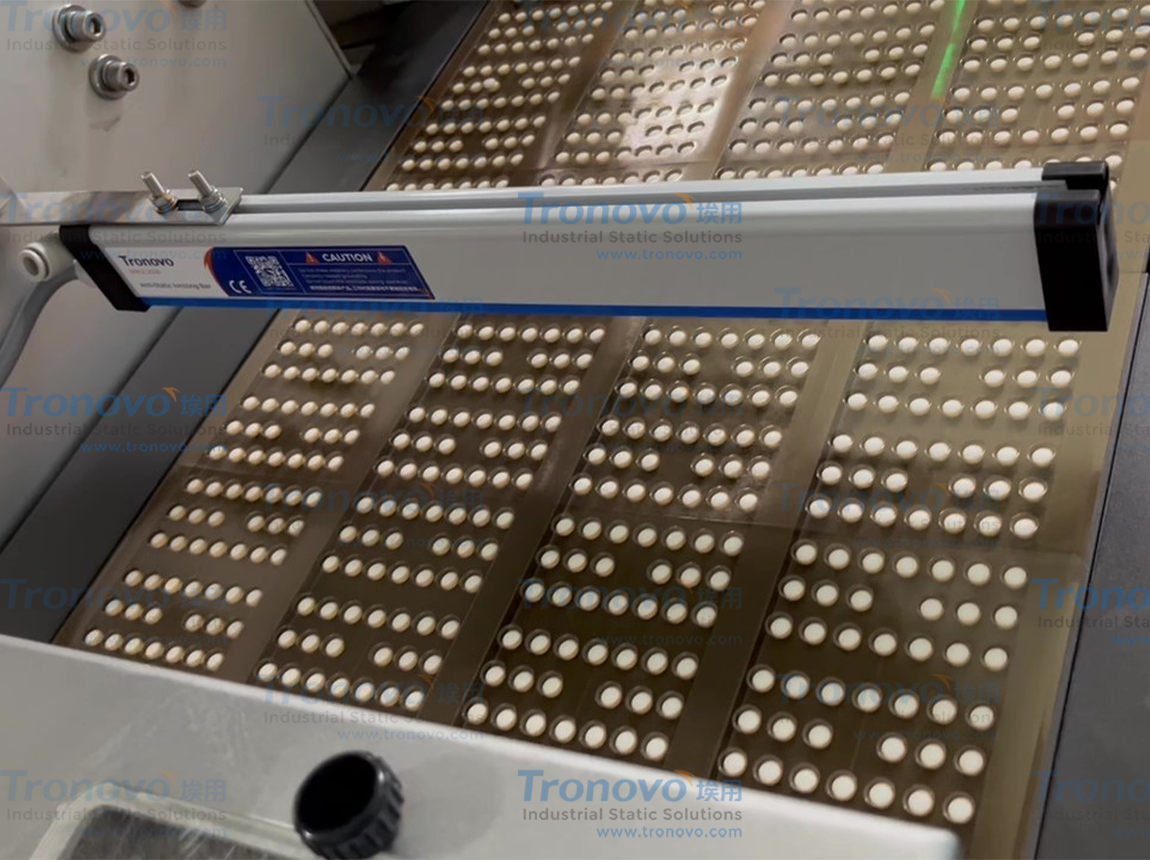

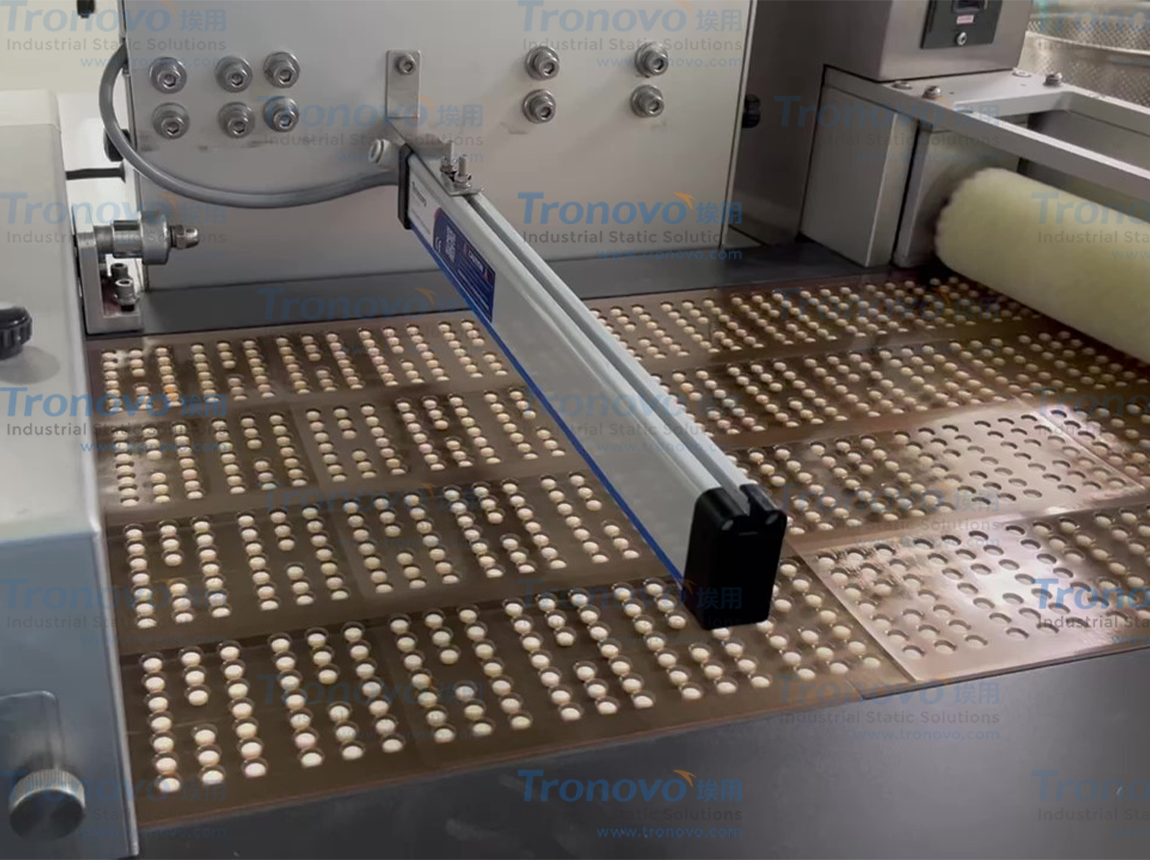

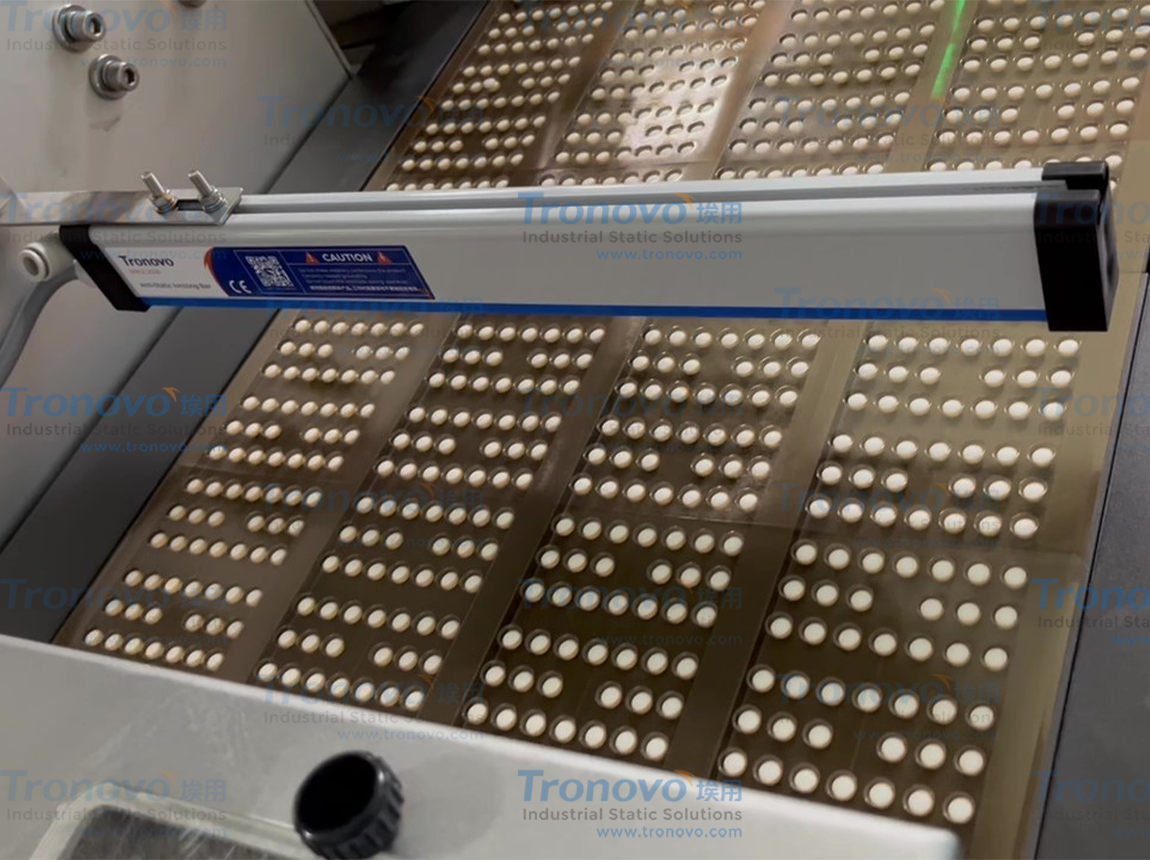

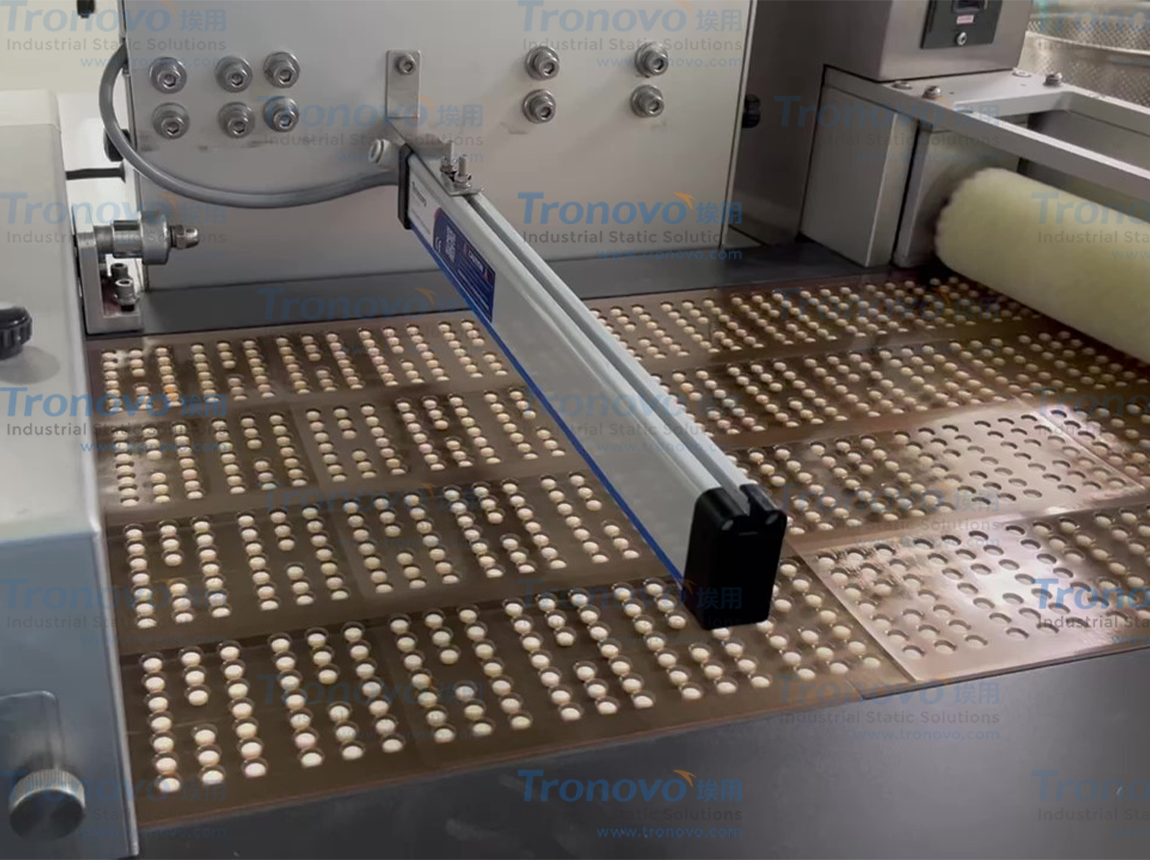

1、In the packing process, install Tronovo high power electrostatic elimination bar.

2, before receiving the container, install Tronovo high power static electricity elimination bar

3、Installed from the product surface height of 4 ~ 5 cm

4, if you need to remove dust, can be connected to clean compressed air, its strong ionized airflow can remove the surface of the static electricity and dust foreign matter.

Keywords: Eyewear static eliminator, ion wind stick, de-static rod, static eliminator, Eyewear static eliminator, Eyewear de-static, ion wind knife, ion air knife, ion rod, industrial static eliminator, ion wind stick, de-static rod, capsule static eliminator, capsule separator de-static device, packaging machine static eliminator manufacturers, static eliminator manufacturers, static eliminator prices, static eliminator brands