Many automated electrical test equipment in the end section of the chip sealing and testing factory, the source of electrostatic charge of the chip in the ATE equipment, mainly include:

1. Handling robot vacuum nozzle pick and place the chip on the chip insulation package shell accumulation of static electricity;

2. Chip loading/unloading process in the test socket, resulting in the accumulation of static electricity in the chip-oriented parts of the test socket.

To solve the chip in the ATE equipment in the ESD failure, the key lies in the chip in the automatic pick and place in the process of electrostatic charge level can be controlled in place, specifically through the ATE related to pick and place the mechanism of the ESD transformation and the chip in the test seat area of the pick and place the process of the ionization of the electrostatic elimination of such technical means to achieve.

Question:

The same batch of chips produced with ATE testing will have higher electrical rejects than those without ATE testing (a good indication that the ESD protection of the ATE equipment is not in place).

Solution:

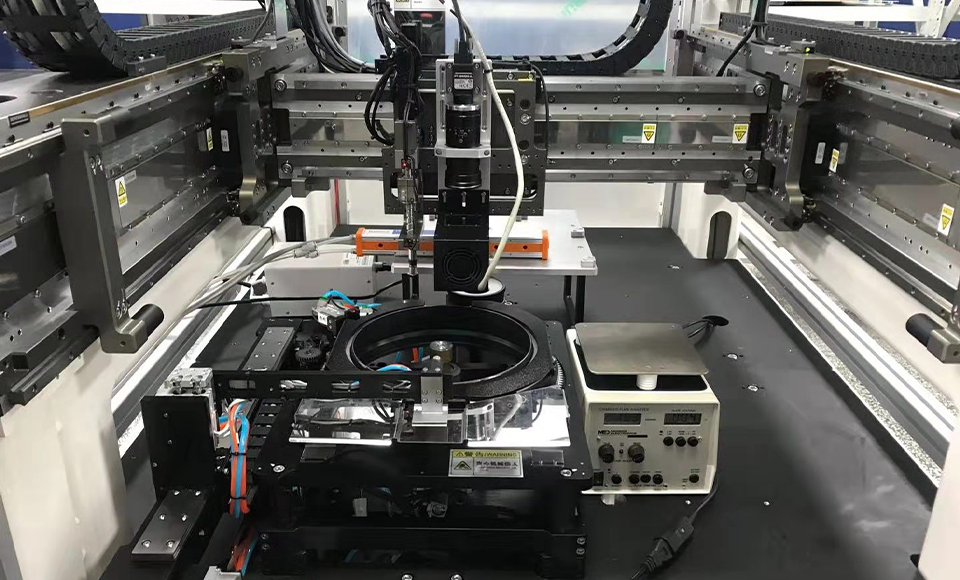

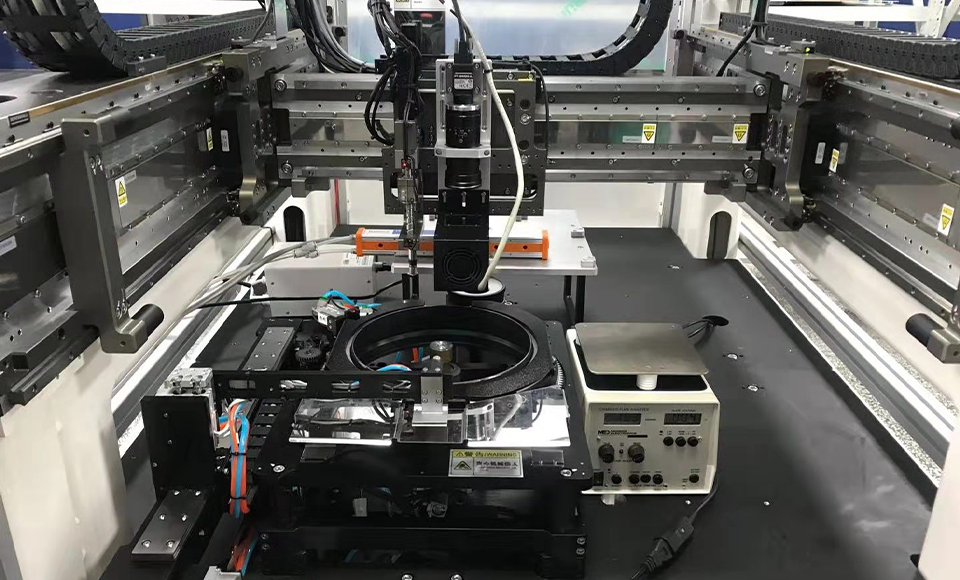

1、To prevent electrostatic damage caused by stripping discharge when picking up and dropping off chips from the nozzle, install the Tronovo electrostatic dissipation bar.

2、Installation distance 30 cm from the product surface

3、Connect clean compressed air and adjust the air flow according to the site conditions.

Keywords: E with static eliminator, wafer static elimination, wafer anti-static, semiconductor chip static protection, ion bar, industrial static eliminator, ion wind rod, de-static bar, static eliminator