70,000Hz high-frequency AC electrostatic elimination technology breaks through the limitations of traditional low-frequency and DC methods, and achieves efficient synergistic release of positive and negative ions through high-frequency AC technology. In the high ion concentration environment, the technology can quickly neutralise the electrostatic charge, the ion balance is stably controlled within ±10V, and the ozone generation is less than 0.05ppm, ensuring no pollution. It does not need to adjust the distance of the characteristics, significantly improve the efficiency of electrostatic elimination, especially for semiconductor manufacturing, precision electronic assembly and other highly sensitive scenes.

Features:

• High-frequency AC electrostatic elimination technology to achieve ultra-stable ion balance within ±10V to ensure precision manufacturing yields.

• Intelligent ion needle monitoring system, reduce 80% maintenance cost.

• Quadruple abnormal alarm function, LED screen display + beeping prompts

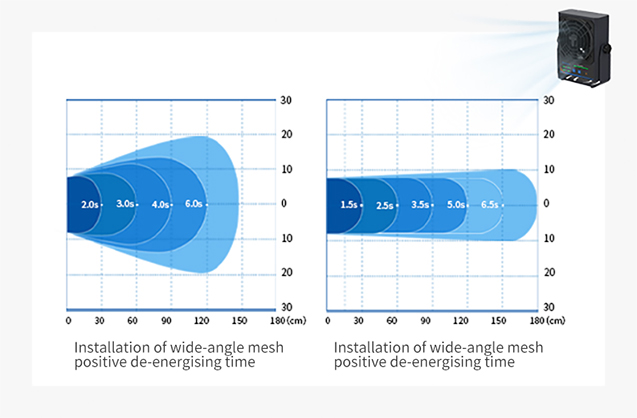

• Dual-mode grille (direct/diffusion), covering a greater distance to eliminate static electricity, suitable for SMT production lines and clean rooms.

• Safety interlock design, open the cover automatically cut off the high-voltage power supply and fan, in line with the safety standard of anti-electrocution.

• 5000rpm turbofan (12-speed adjustable), wind speed of 0.5-5m/s to accurately match the needs of electronic assembly/film roll process.

• Industrial Internet of Things (IoT) integration, supporting IO control interface.