Application case of rotating nozzle for dust removal of automobile bumper

Project Background:

With the continuous development of automobile manufacturing industry, the requirements for surface treatment accuracy of parts are increasing day by day. As a key component of the car body, the dust and static electricity attached to the surface of the car bumper will directly affect the adhesion effect of the primer, resulting in quality problems such as coating blistering and falling off. Therefore, in the dust removal link before bumper spraying, effectively eliminating static electricity has become the key to improving product quality.

Solution:

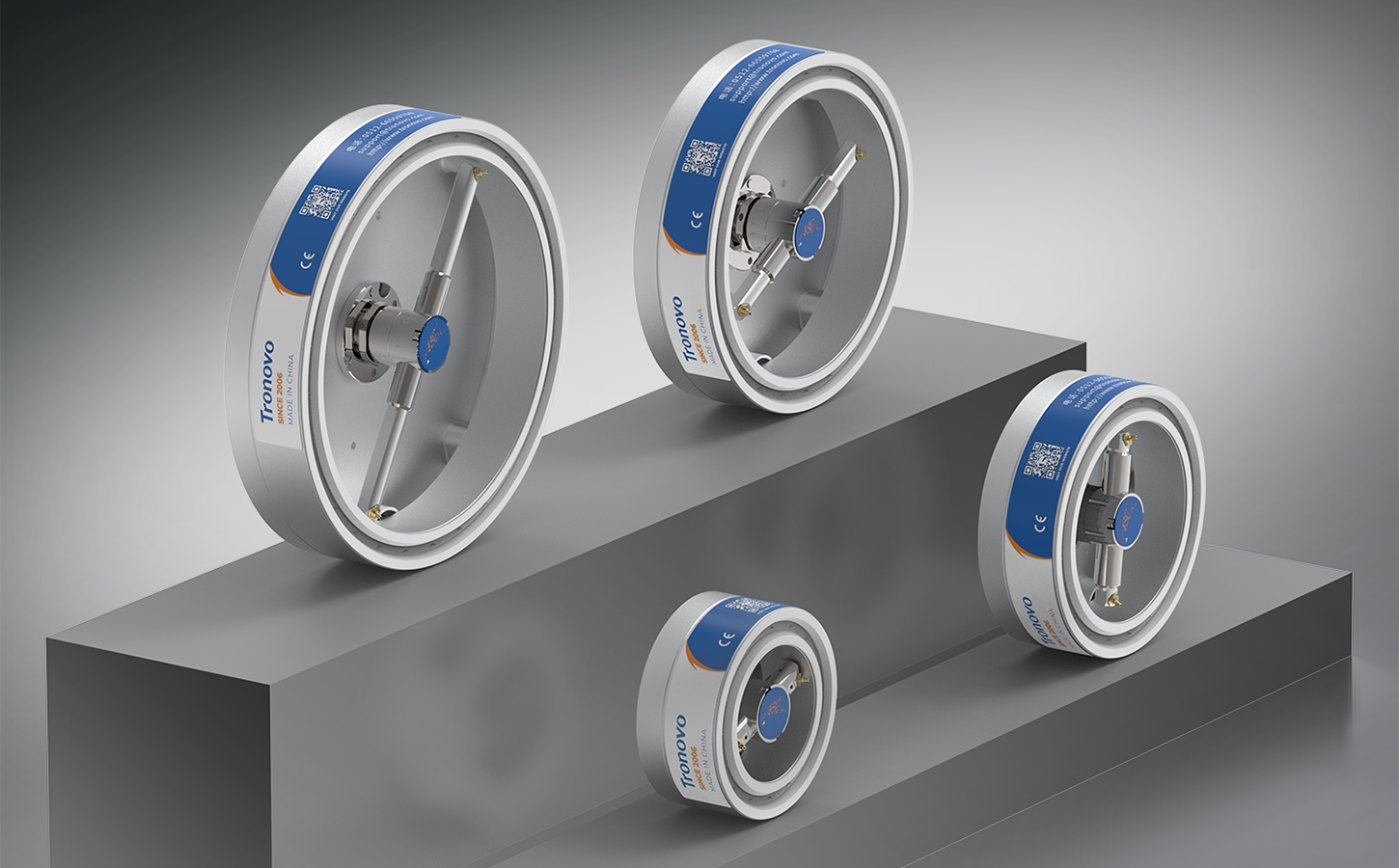

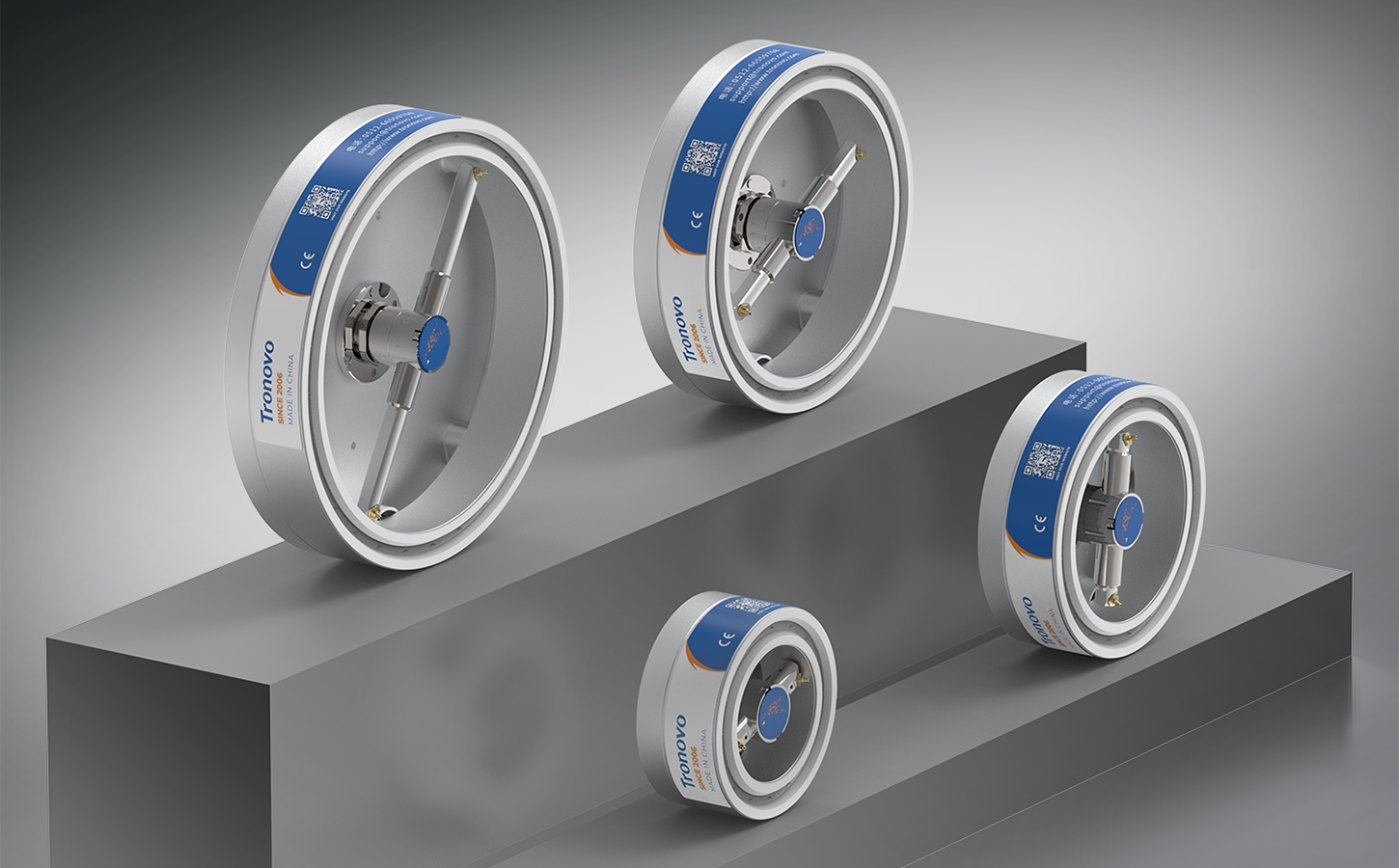

In order to meet these 1 requirements, a large-scale cyclone ionizer dust removal equipment is applied to the pretreatment process of the bumper production line in an auto parts factory. The ionizing nozzle generates uniform airflow through the high-speed rotating nozzle, and releases positive and negative ions at the same time. While purging the surface dust, it quickly neutralizes the static electricity on the bumper surface. The rotating design ensures that the air nozzle can cover the complex curved surface of the bumper at 360 °, there is no dust dead angle, and the fine particles in the gap are completely removed.