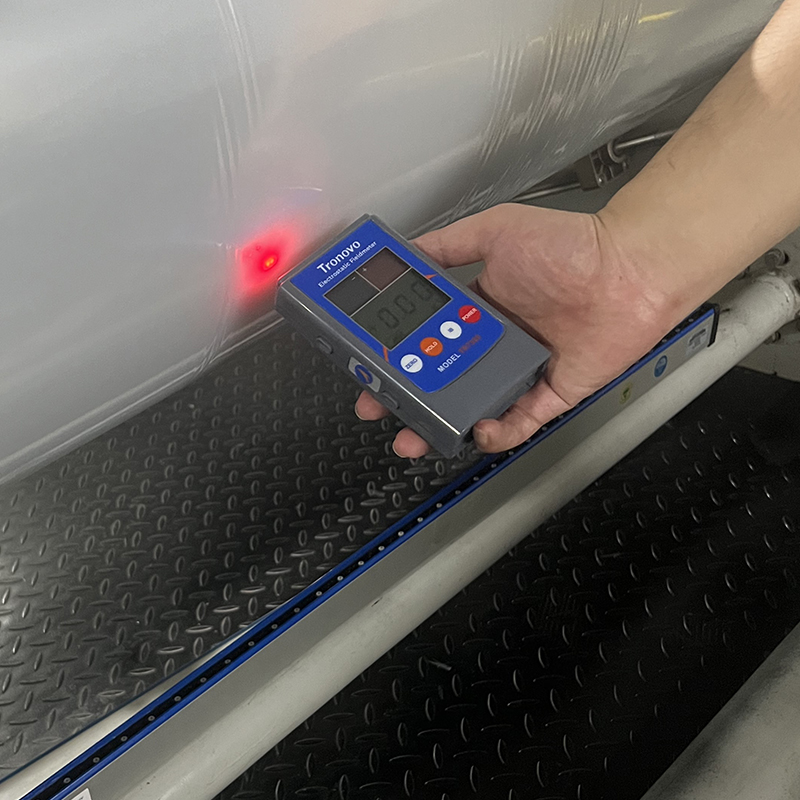

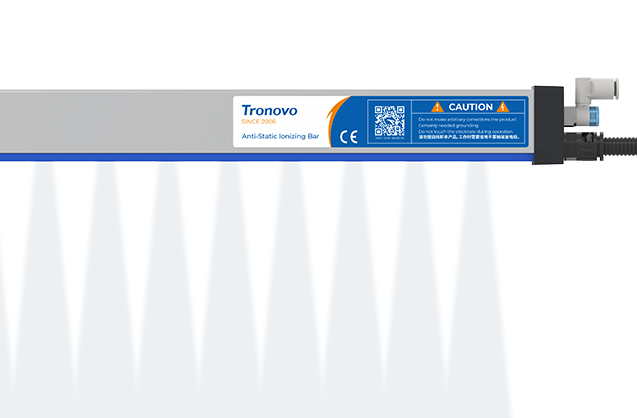

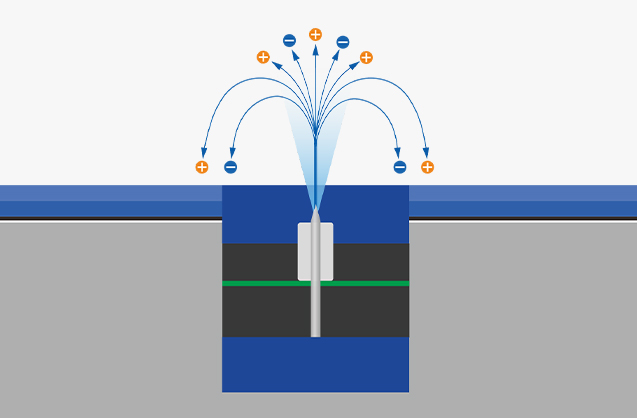

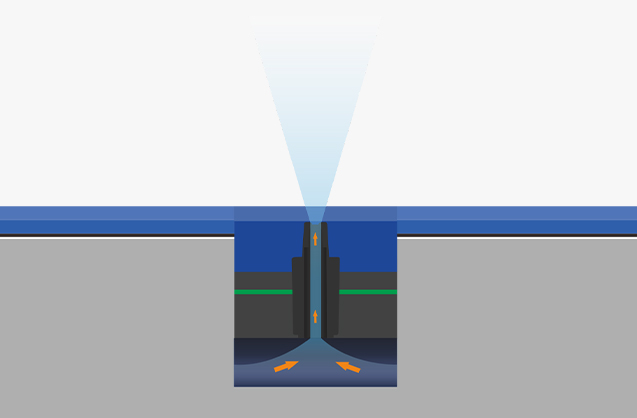

The industry benchmark! After tens of thousands of customers' on-site installation and use, the ultra-high repurchase rate has proved its excellent quality and performance. Its innovative technology and high-grade materials enable it to quickly, effectively and reliably remove surface static electricity from the production process even at medium to high speeds. The design with air source gives it the ability of ionic air knife, which can act on a long distance of more than 50cm. Thanks to its high-speed airflow, it is able to blow away foreign matter adsorbed by static electricity, making it a powerful assistant in industrial production and a trusted choice for customers.

Features:

• Excellent stability, high-quality materials, can ensure long-term use results

• Resistance coupling technology, no electric shock, to ensure the safety of the operator

• Efficient antistatic performance, fast elimination of static electricity

• Gas-tight high-voltage plug with flexible coaxial shielded cable

• Longer range, can be applied to more than 60cm distance

• Use flame retardant PVC environmental protection material

• Easy to install, use removable mounting bolts to install

• Appearance using aluminum material, easy maintenance