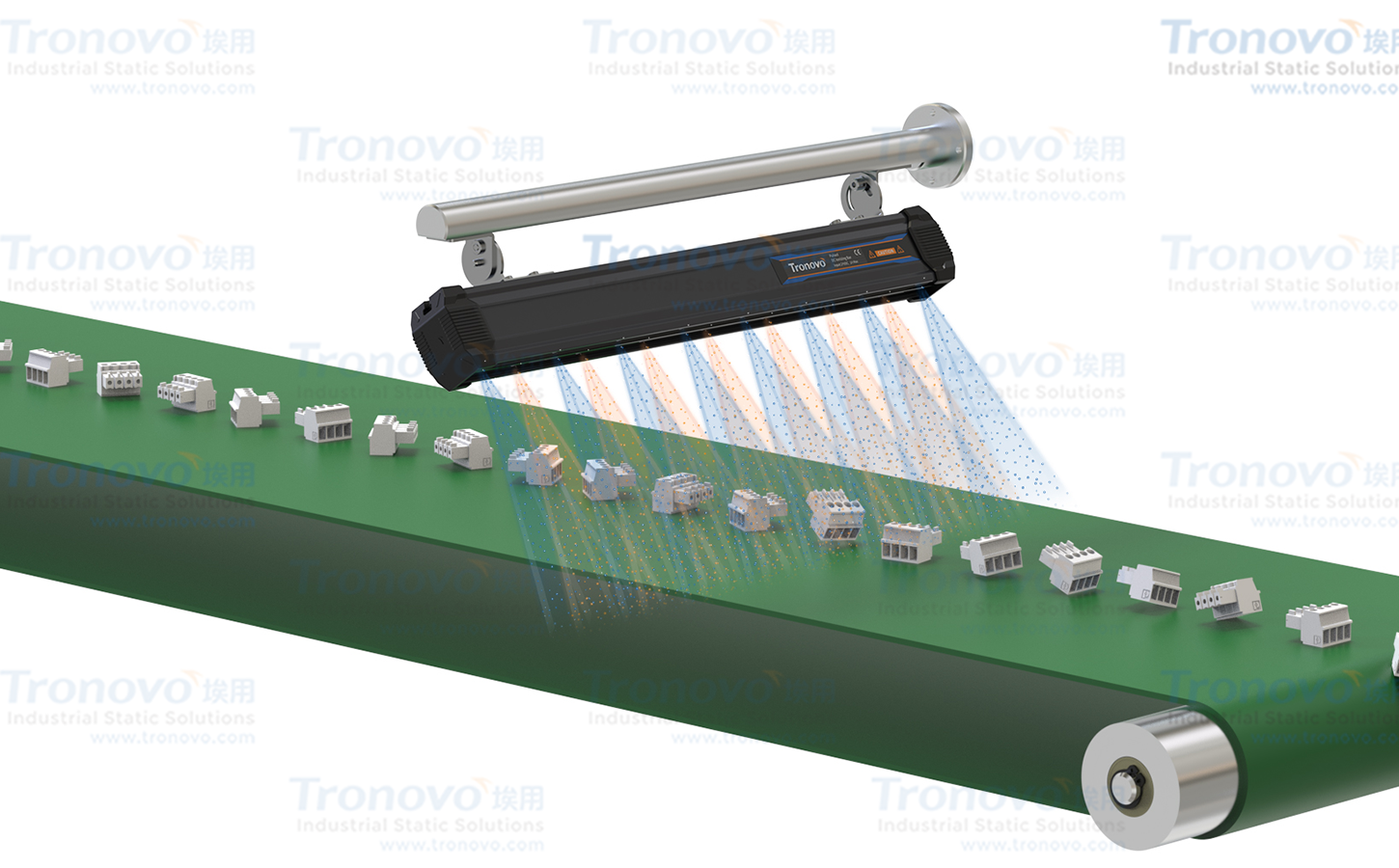

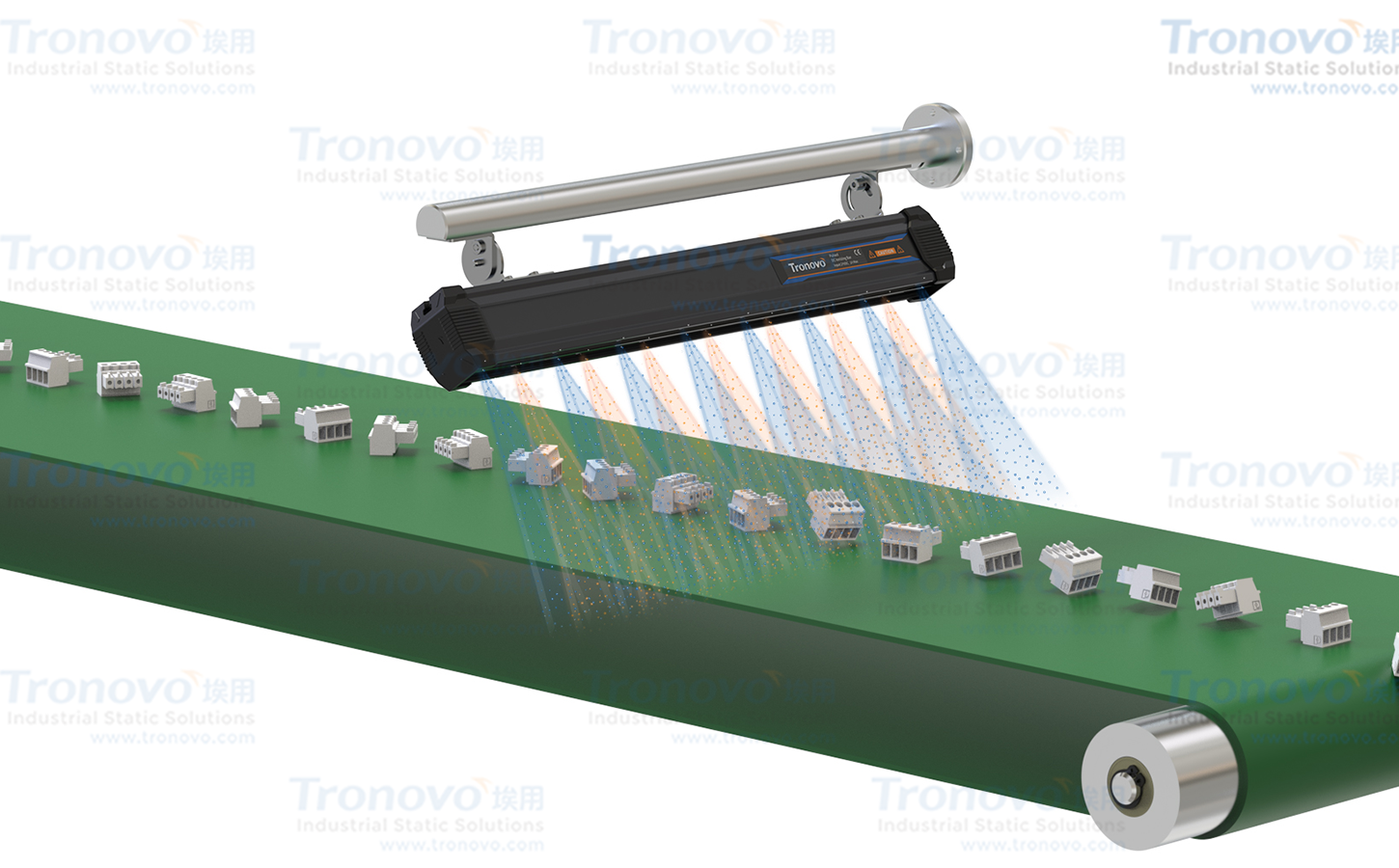

DC Ionizer Bar Eliminates Electrostatic Adsorption of Plastic Parts of Conveyor Belt

Project Background:

In the plastic parts conveyor transport process, static electricity affects the smoothness of production. When plastic parts are transported on the black conveyor belt, static electricity is easily generated on the surface due to frequent friction with the conveyor belt. The problems caused by this lead to abnormal stacking, and the parts with static electricity stick to each other. When falling into the carton link, the parts that should have been returned orderly are often misplaced due to electrostatic adsorption force, and even stuck in the gap between the transmission end and the carton, thus disrupting the blanking rhythm;

Solution:

In order to solve the above electrostatic problems, we have precisely installed a pulsed DC ionizer bars directly above the conveyor belt. When a plastic part with static electricity passes under the anti static ionizer bar, the opposite polarity ions released by the bar type Ionizer will quickly neutralize the electrostatic charge on the surface of the part.