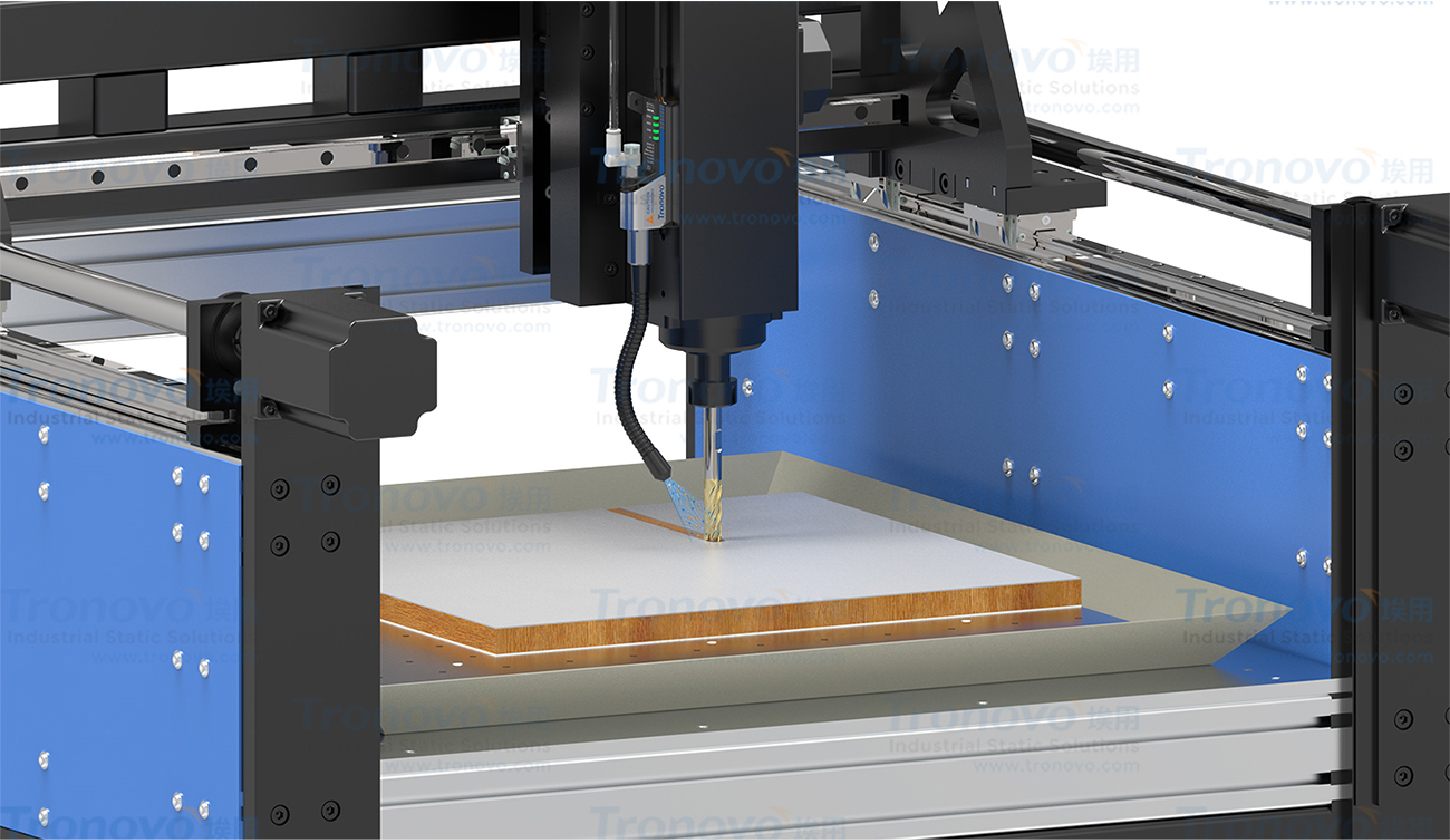

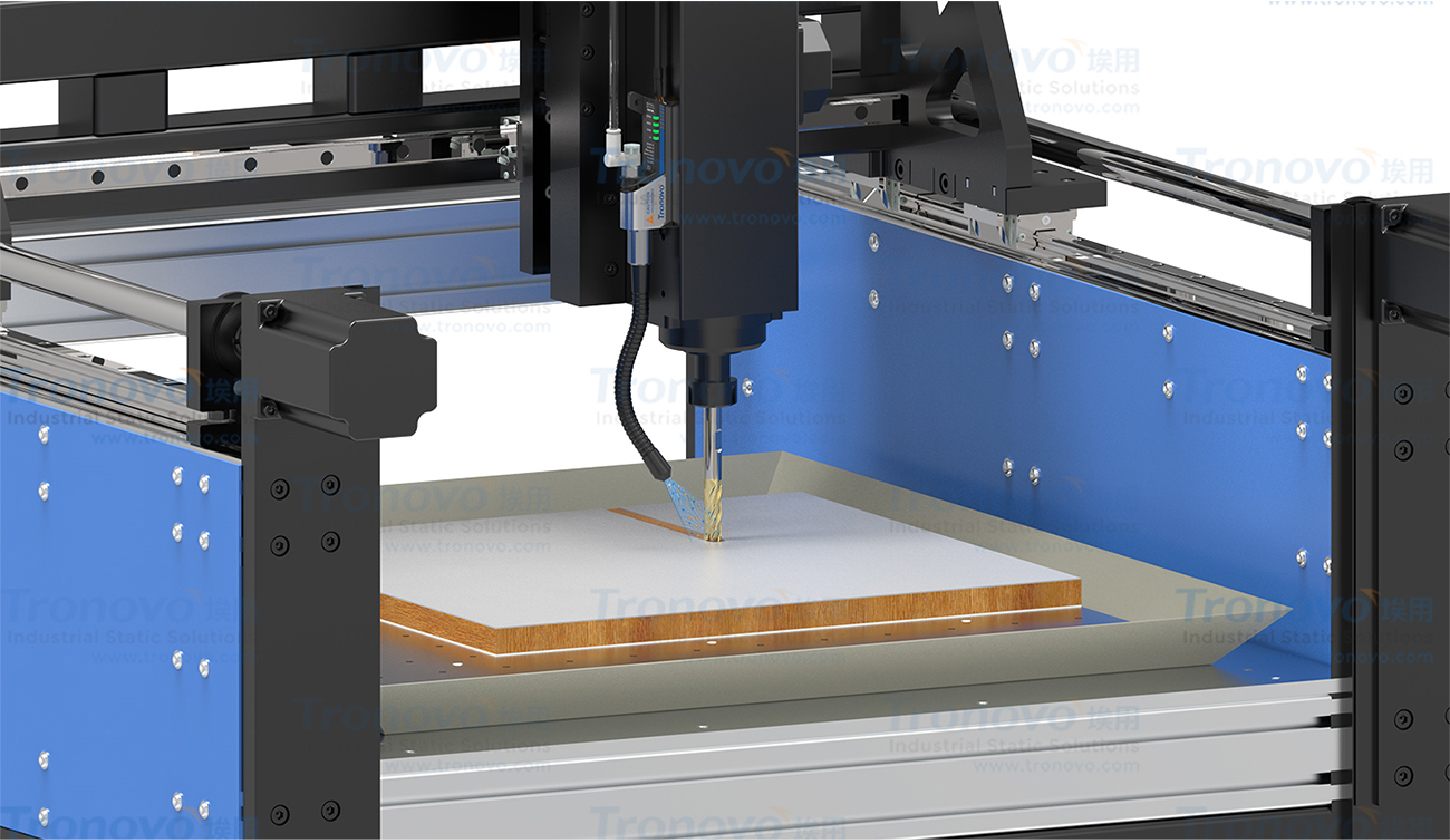

Application case of electrostatic dust removal in milling machine processing

Project Background:

During precision milling of wood boards, the high-speed friction of the cutting tool causes sawdust and wood powder to accumulate due to electrostatic adsorption, causing multiple problems: the adhesion of wood powder to the surface of the workpiece leads to dimensional measurement deviation, surface roughness exceeding the standard, and the defective rate of the finished product increases; Electrostatically adsorbed wood powder accumulates at the main shaft and circuit, causing circuit alarm and equipment shutdown. When the charged workpiece is painted and veneered, it is easy to adsorb impurities, there are pinholes, orange peel, poor fit and other quality problems.

Solution:

The ionizing nozzle is installed at the cutting part of the spindle tool, and the ionizer air flow of the universal nozzle purges the dust that loses electrostatic adsorption, and simultaneously completes electrostatic elimination and surface cleaning.

Core Advantages:

The Nozzle type ionizer accurately covers the cutting point; Directly act on the surface of charged objects, and the static elimination time is less than 1 second; The static eliminator has 24V low voltage power supply, which meets the safety standards.