Case study of surface electrostatic dust removal during pipeline production

Project Background:

Metal/plastic pipes generate static electricity due to friction during cutting and transportation, adsorb environmental dust, resulting in surface pollution and coating "fish eyes", orange peel, decreased adhesion, coating defects, and soaring rework rate. Electrostatic adsorption debris causes sealing ring installation deviation, assembly failure and sealing failure.

Solution:

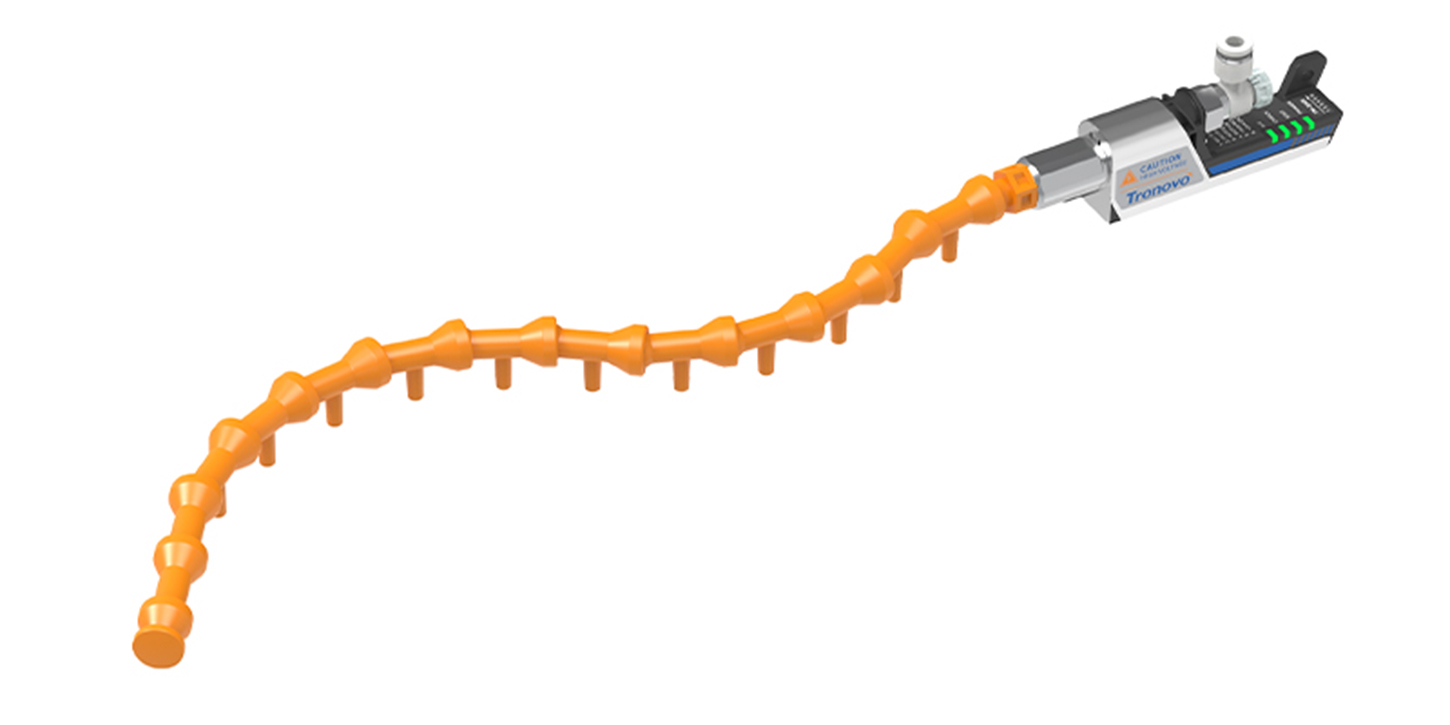

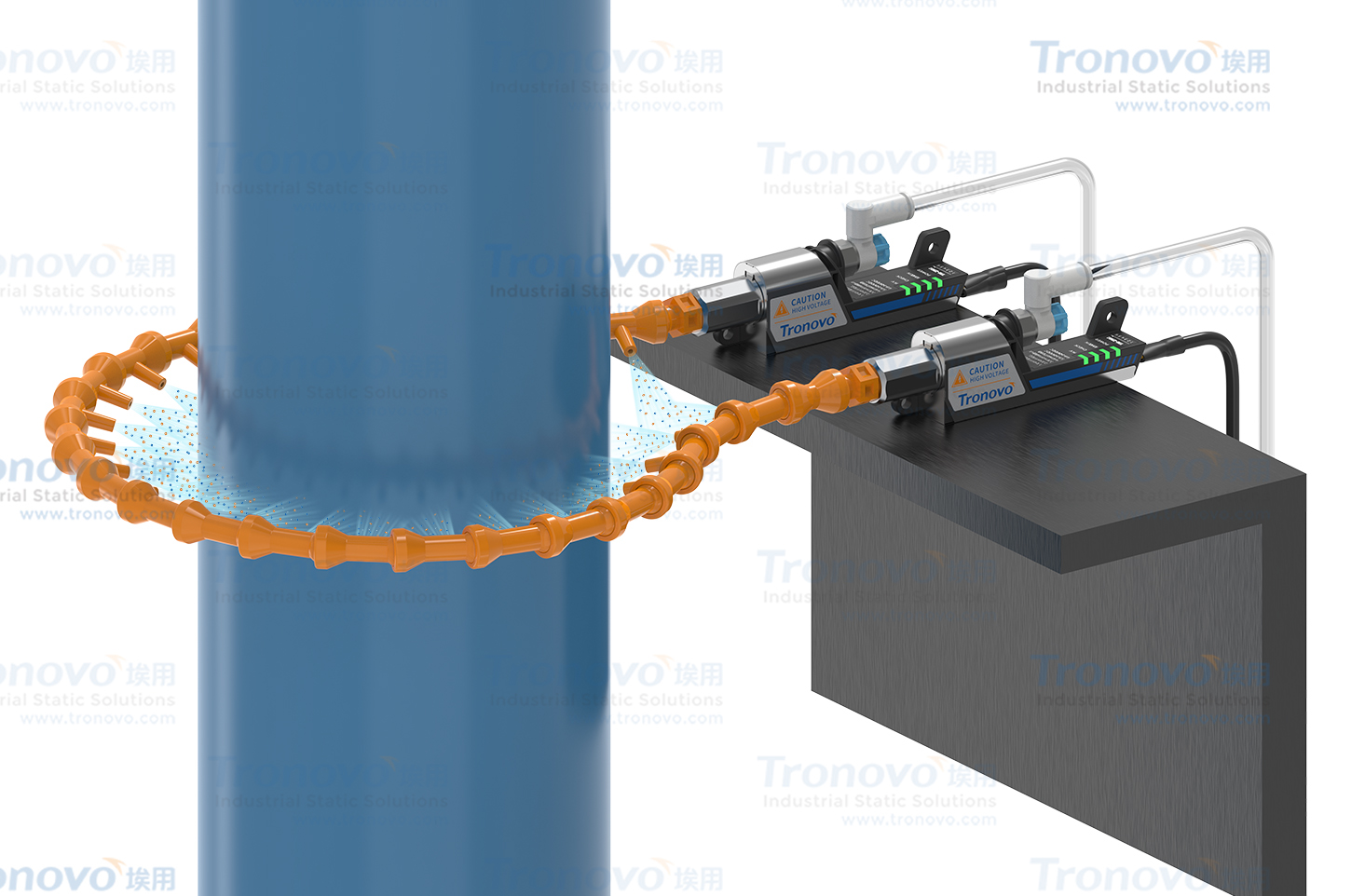

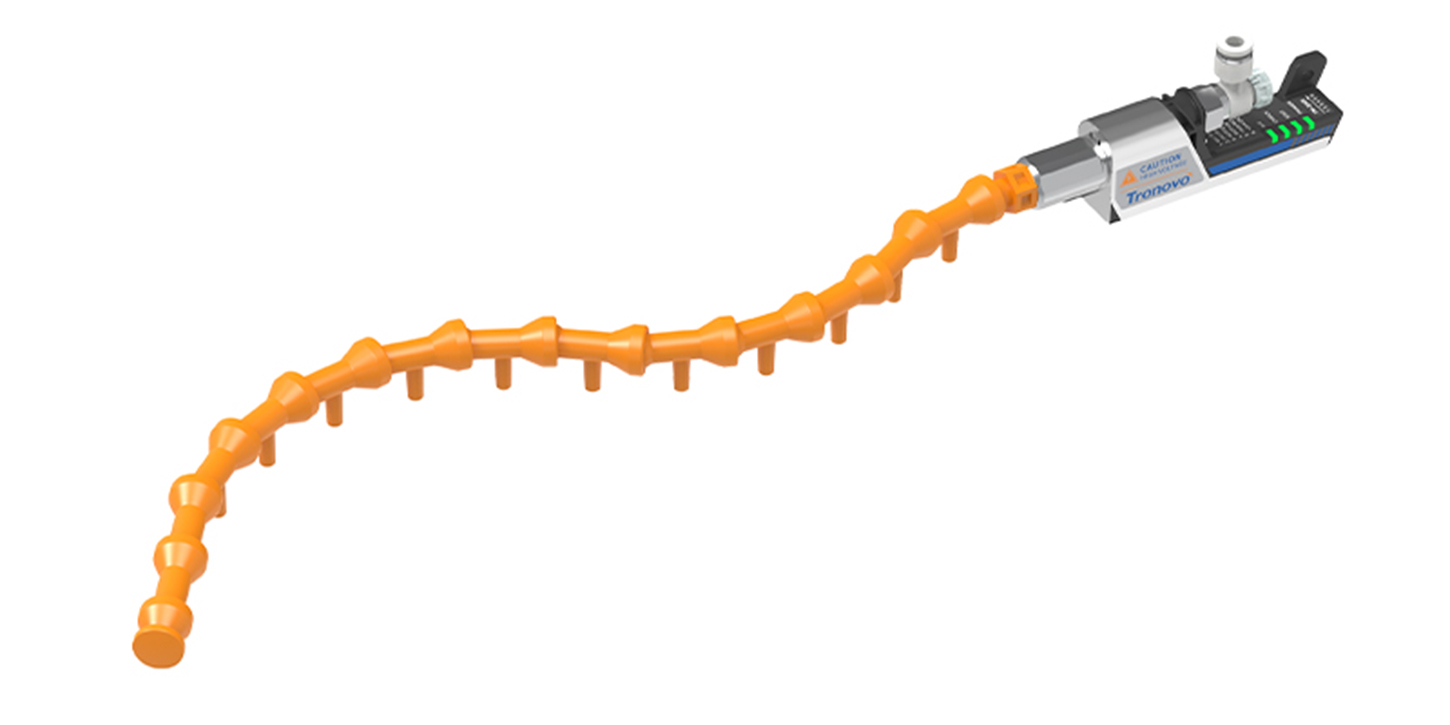

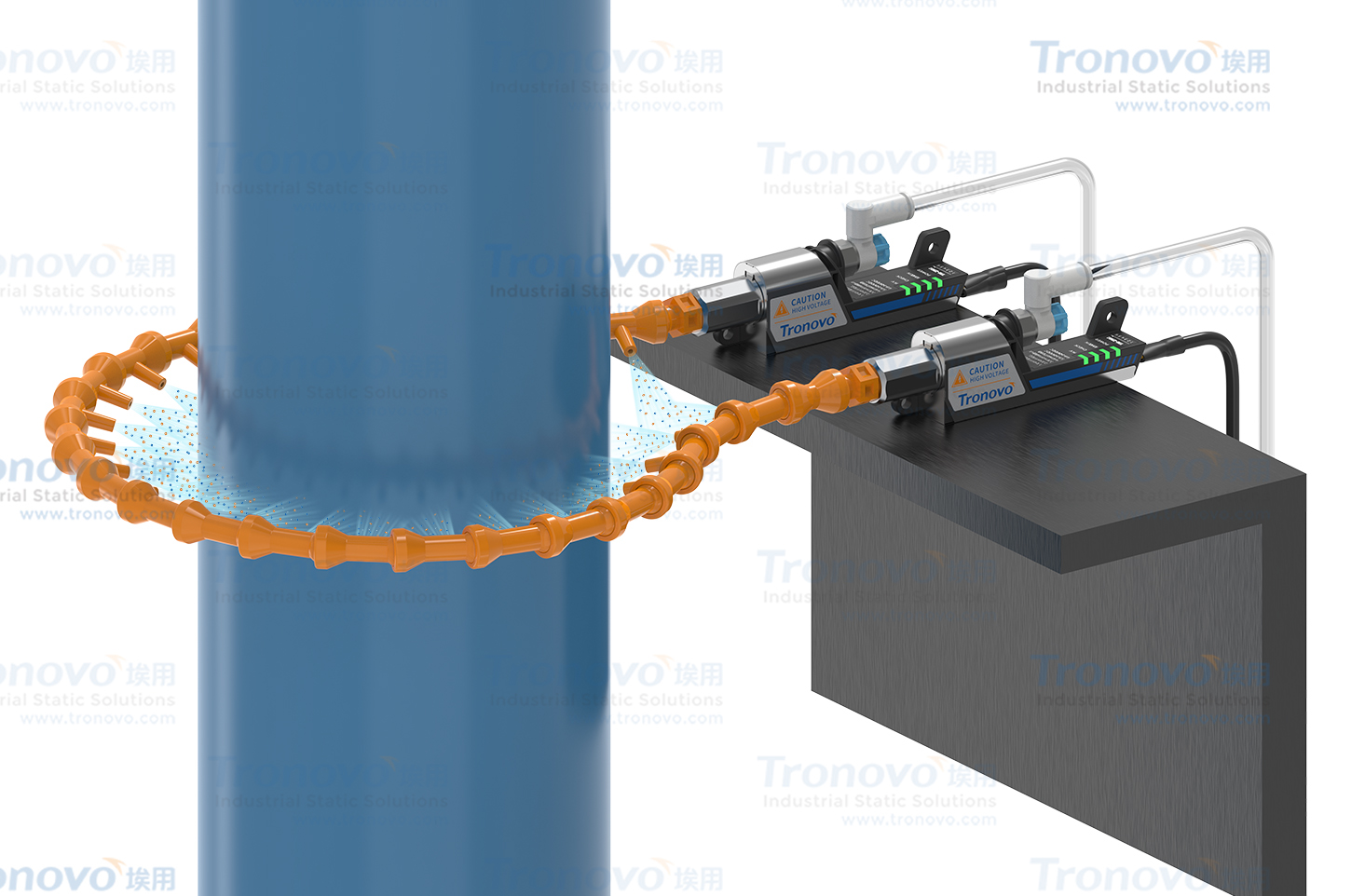

Before the pipeline enters the coating line, the surface generates strong static electricity due to friction, which quickly absorbs particles in the air in the workshop. The tip of the ionizer nozzle is used to generate a large number of positive and negative ions, which are blown out through the annular slub pipe to cover the pipeline surface.

Core Advantages:

The annular universal nozzle bends flexibly, fits the curved surface of the pipeline, and has no dead angle ionizing coverage; The Nozzle type ionizer cooperates with dust removal to simultaneously complete static elimination and surface cleaning; It is suitable for different pipe diameters (especially circular pipes), and the static eliminator nozzle is easy to install and maintain;