Tronovo Pulsed AC Ion Bar Solves SMT Feedar Throwing Problem

Pain Point Diagnosis: SMT Feida Material Throwing Problem Seriously Affects Production Efficiency

An electronics factory F005 placement machine station production time-frequency SMT fly up to throw material, resulting in a decline in SMT patch yield, mainly as follows:

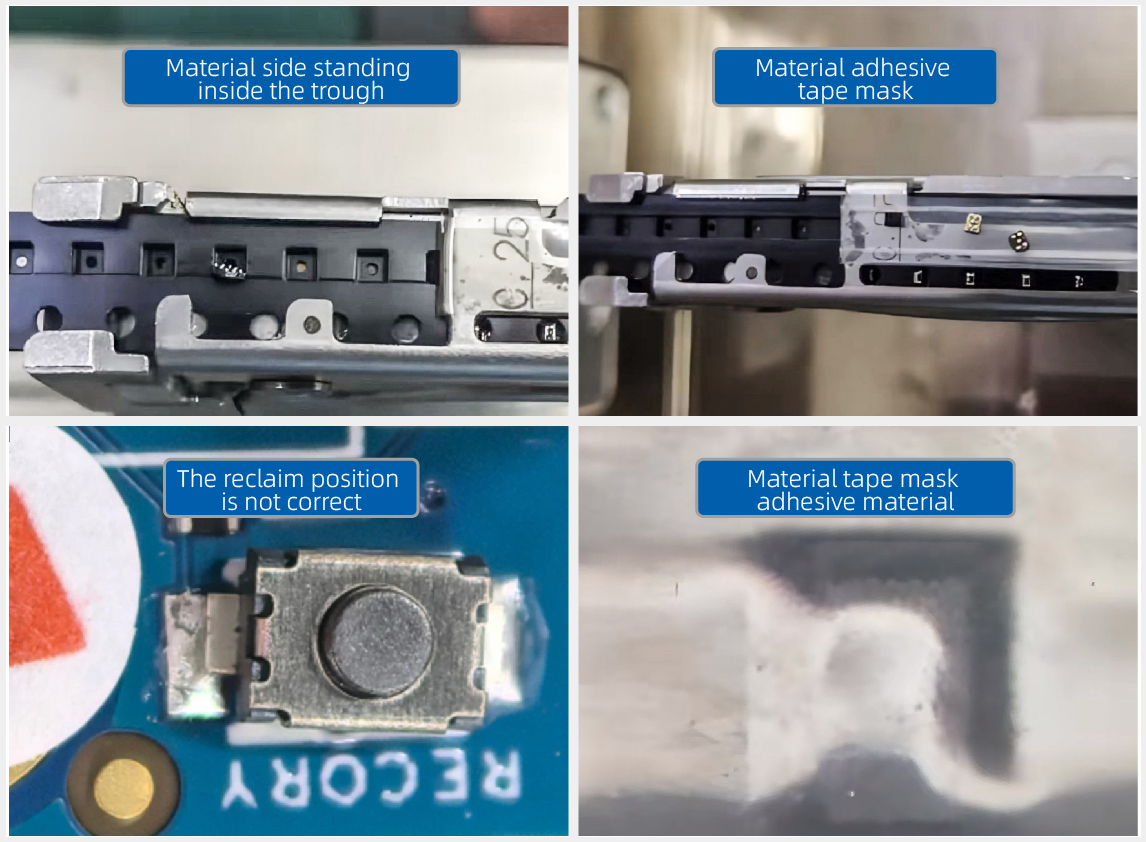

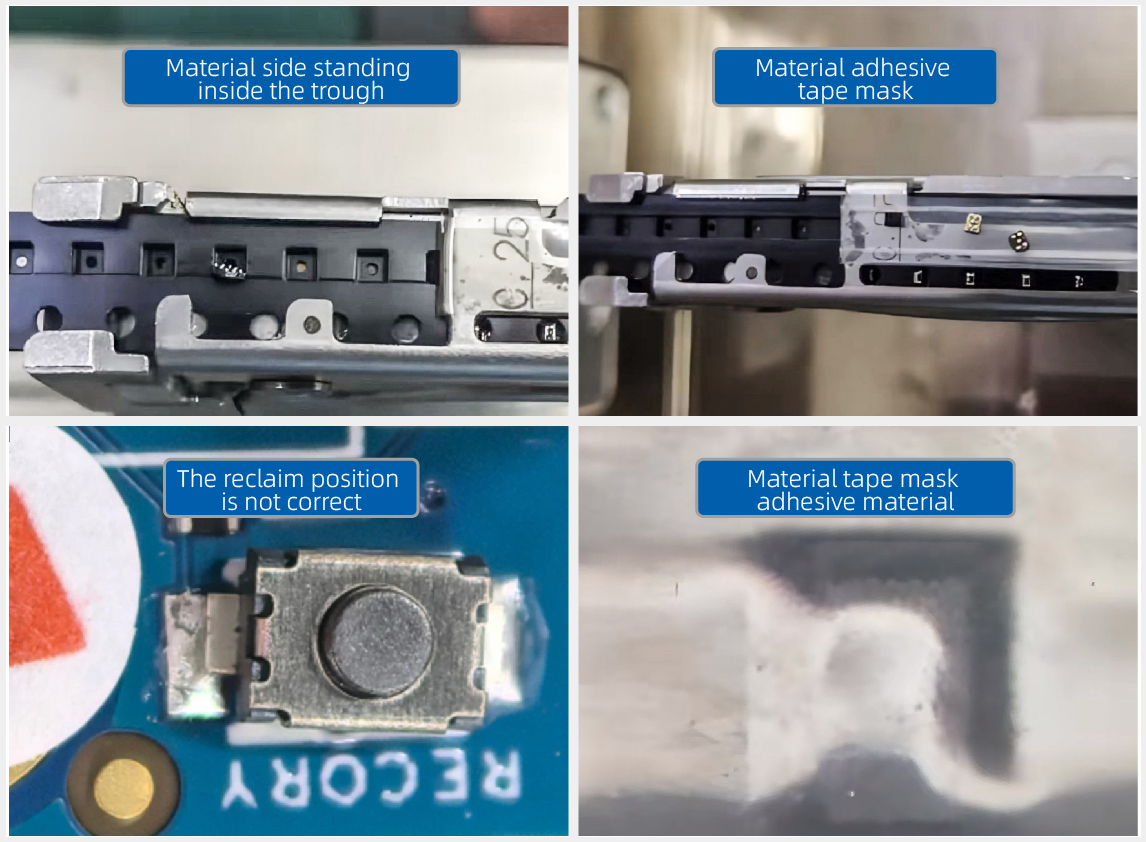

1. Component adsorption offset: static electricity causes the 0201 resistance to stand/turn over sideways, and the suction nozzle has an empty grip rate of 13.3;

2. Film stripping tape: when the tape is separated, the electrostatic charge soars to ± 8kV, causing the component adhesion carrier tape to be forcibly taken out.

Average monthly material loss of 3.2 per cent, 0201 resistance loss alone, I .e. over $15000 per month.

Solution Deployment:

1. Accurate static positioning, optimization of SMT feeder stability

A pulsed AC ion bar is installed 200mm directly above the SMT Feeder feeder, and its 300mm wide ion air curtain completely covers the strip stripping area to ensure efficient neutralization of static electricity. The equipment display screen monitors the working status in real time to improve the stability of SMT feeder.

2. Anti-static Optimization Plan for Tape and Mask

Anti-static Tape and Mask: Utilize anti-static materials to prevent static accumulation that could cause component displacement or adhesion.

Anti-adhesion Treatment: Apply a special coating to the surface of the tape and mask to ensure they do not stick to each other, avoiding the removal of components during peeling.

Packaging Optimization: Add a separator layer when packaging the tape and mask to prevent material adhesion during transportation or storage, ensuring smooth SMT feeding.

Implementation Results

Significant Reduction in Scrap Rate: Decreased from 3.2% to 0.38%, with the suction nozzle pick-up success rate increasing to 99.1%.

Annual Cost Savings of $160,000: Monthly loss of 0201 components reduced from 15,200 to 1,850.

Improved Line Compatibility: Applicable to high-static scenarios involving 0201/01005 and other micro-components and IC carrier tapes.