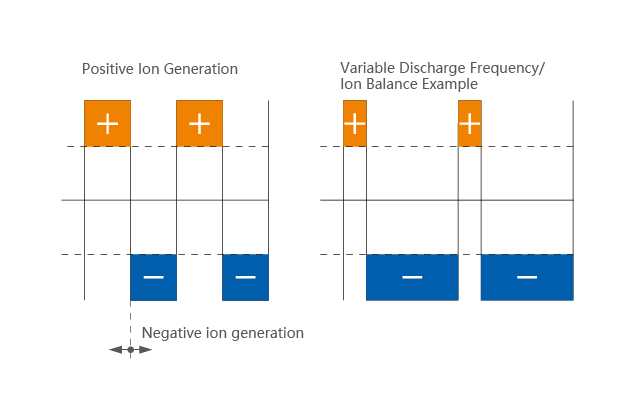

Pulse AC Ionizer adopts high frequency pulse modulation technology, which greatly improves the electrostatic neutralization ability, instantly releases high density positive and negative ions, and precisely regulates the ion balance, far exceeding the continuous output mode of traditional AC Ionizer. Its pulse characteristic not only reduces ion needle dirt and extends the service life of pure tungsten ion needle, but also adapts to the static control needs of PCB board assembly, semiconductor manufacturing, high-speed film winding and other demanding scenarios. It supports 50-1500mm industrial static elimination, and the intelligent adjustment function can adapt to the change of material polarity (e.g. plastic to paper roll). In addition, the low energy consumption design can reduce the comprehensive cost by 30%, significantly improve the efficiency of the electronic production line, and protect the quality of electrostatic sensitive products.

Product features:

• Advanced modulation technology increases ion generation by 40% and eliminates static electricity more efficiently.

• Ion balance is fully compliant with the electronics industry standard of electrostatic protection.

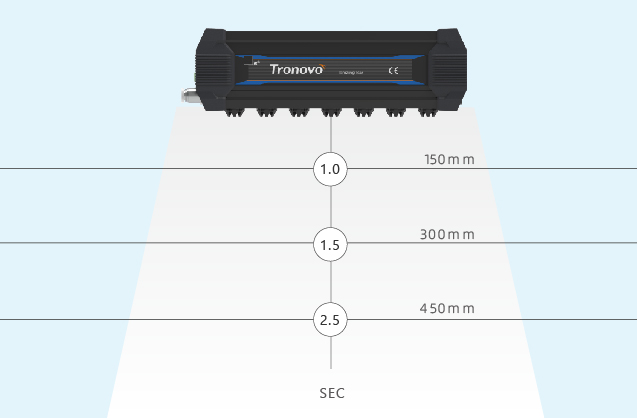

• Multi-level frequency technology automatically optimises the frequency setting according to the working distance.

• Alarm lights indicate high voltage.

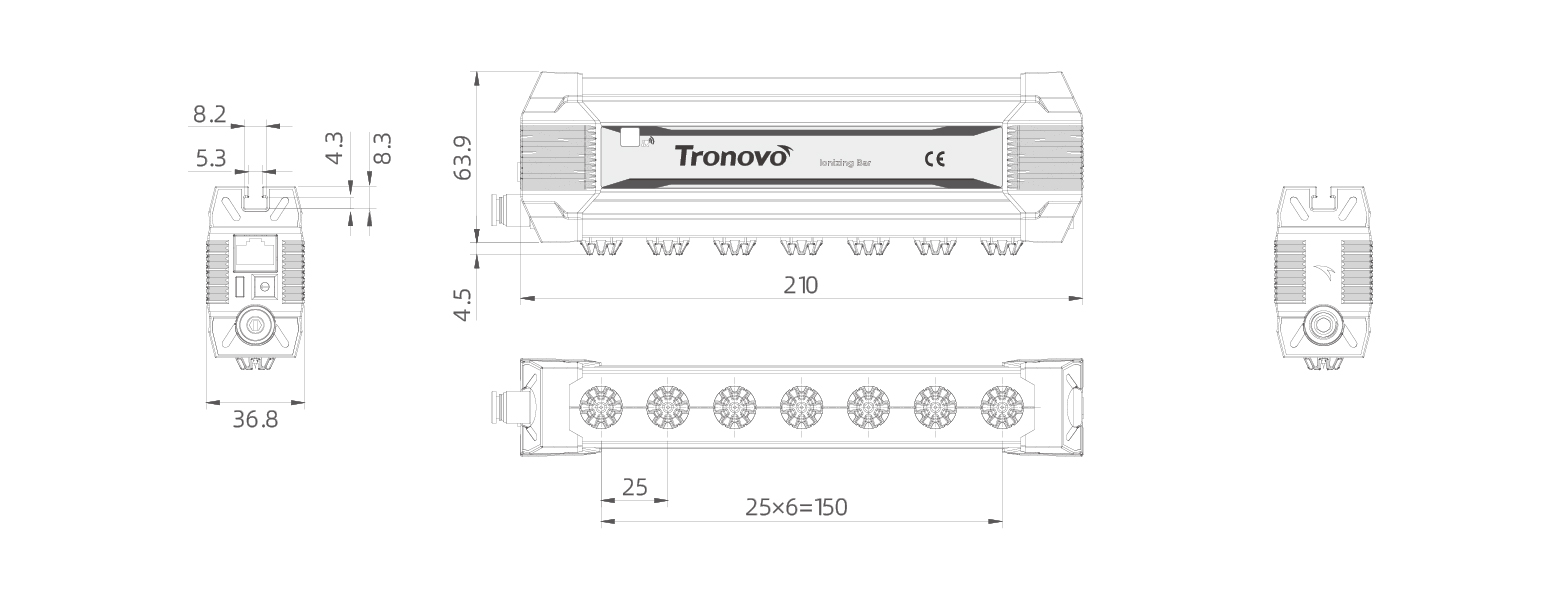

• Modular air nozzle ion needle design reduces the maintenance cost of electrostatic elimination equipment.

• Modular air nozzle ion needle design, rapid replacement to reduce the maintenance cost of electrostatic elimination equipment

• Intelligent cleaning alarm function triggers maintenance automatically.

• Supports PLC control interface.