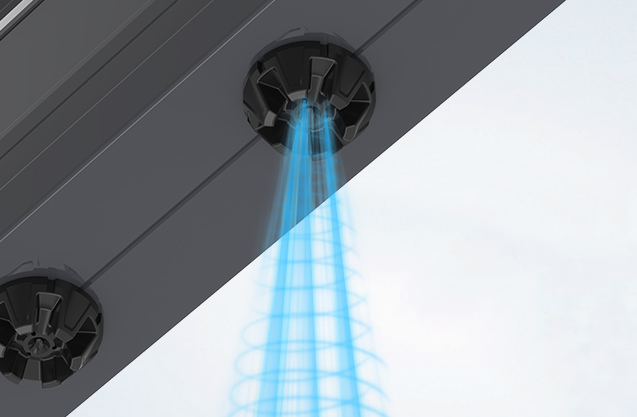

Pulse AC Ion Bar adopts high frequency pulse modulation technology, the electrostatic neutralization ability is greatly improved, it can instantly release high density positive and negative ions, compared with the traditional AC Ion Bar continuous output method, it can more accurately regulate the ionic balance, and at the same time, reduce the ionic needle dirt, prolong the service life of pure tungsten ionic needle. The technology is especially suitable for PCB assembly, semiconductor packaging, high-speed film winding and other industrial scenarios with stringent requirements for static control, and can adapt to the static characteristics of different materials (such as plastic, paper). Its low-energy design can reduce operating costs by 30%, significantly improve the efficiency of electronic production lines, and protect the production quality of SMT placement, precision electronics manufacturing and other fields, which is an ideal solution for industrial static electricity elimination.

Product Features:

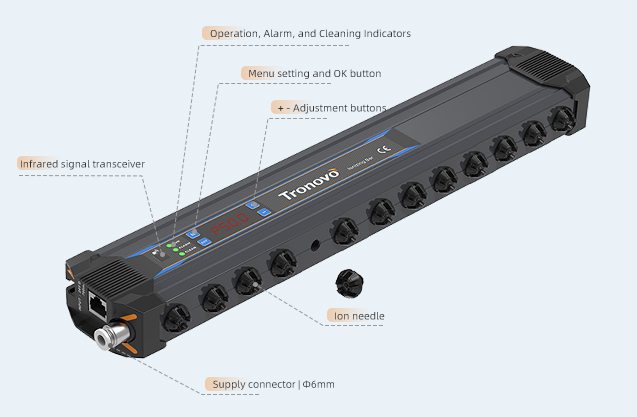

• Pulse AC Ionizer: High-speed static electricity removal.• Adjustable ion balance: Precise within ±35V, meeting IPC-A-610 standards.

• Intelligent frequency adjustment: Positive and negative ion output frequency (10-100Hz).

• Supports proximity PCB boards (30mm) and long-distance clean room space (2000mm).

• Industrial-grade status indicator: Dual-color LED work indicator, high-voltage abnormal red light alarm.

• Intelligent maintenance reminder: Automatically detects cleaning alarm function.

• Automation integration program: Supports PLC control, RS485 communication.