Case of electrostatic removal in powder medicine canned

In the production and packaging of powder drugs, electrostatic control is a crucial link. Due to the small particles of powder drugs, they are prone to static electricity in processing, transportation and packaging. These static electricity will not only cause powder adsorption, flying or accumulation, which will affect the uniformity of the drug and the accuracy of the dose, but also may cause serious safety accidents such as dust explosion, which poses a threat to the health of the staff and the safety of the production environment. In addition, static electricity may also affect the packaging quality of drugs, leading to problems such as lax sealing and product contamination, thereby affecting the quality and efficacy of drugs.

Problem DescriptionDust adsorption and pollution: static electricity will attract dust and impurities in the air, resulting in drug pollution, affecting product quality and efficacy. Although the environmental control of the dust-free workshop is relatively strict, static electricity may still cause dust adsorption and contaminate the finished product.

Product adhesion and agglomeration: electrostatic powder drugs in the process of mutual adhesion, or adsorption on the inner wall of the equipment, affecting the production efficiency, resulting in waste of raw materials, and may cause production line blockage.

Inaccurate weighing: In the process of weighing powder medicine, static electricity may cause the weighing equipment to display inaccurate results, especially in the case of precise dosage, electrostatic interference may lead to dosage errors, affecting the safety and effectiveness of the drug.

Solution

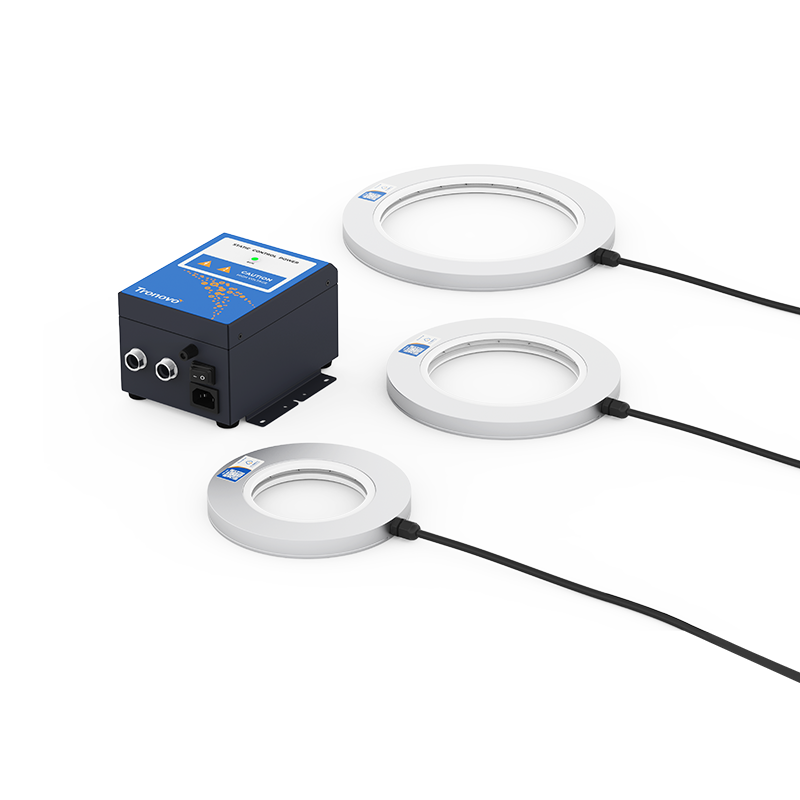

SolutionPlace the semicircular static eliminator along the upper material tray, and point the ion needle between the medicine bottle mouth and the powder filling mouth. This allows the ions to neutralize the static electricity between the powder filling port and the bottle mouth during the canning process, effectively preventing dust during the canning process.

ConclusionThrough the comprehensive static elimination measures, the electrostatic problem in the process of powder medicine canning can be effectively controlled. These measures not only improve production efficiency and drug quality, but also enhance the safety of the working environment. Future work should continue to focus on the latest developments in electrostatic control technology and apply them to actual production to achieve a more efficient, safer and more environmentally friendly powder pharmaceutical production process.