Die-cutting machine installation static eliminator case

Concern

1. Product attaches to the edge of the organizer

2. After the product comes out of the static electricity can not be organized, straighten out the

3. The product will follow the mold and stick to the mold.

Prescription

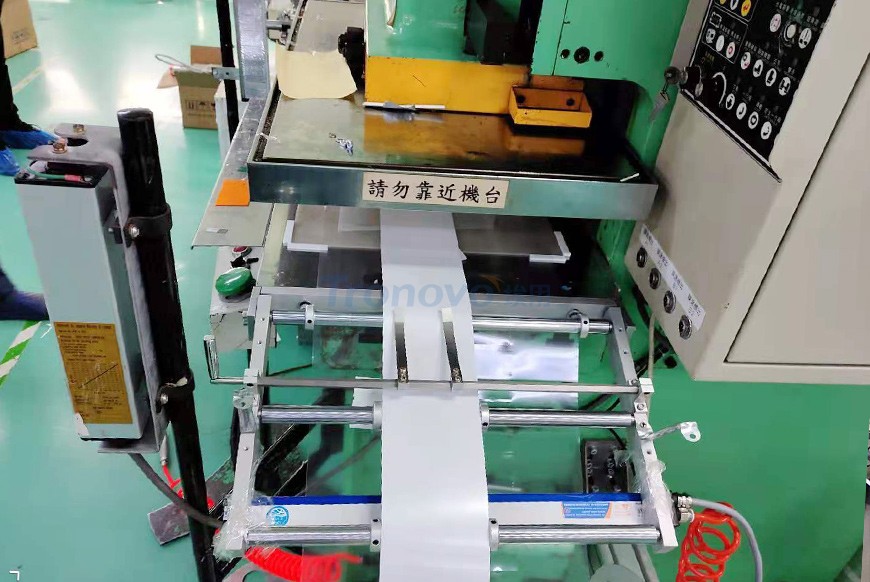

1. Above the outlet position, install the Tronovo electrostatic discharge ionizer TR8630, 1 unit, at a height of 5 cm.

2. Installation of Tronovo's de-static ionization bar TR8630, 1pc, at the membrane separation point

On-site Questions and Answers

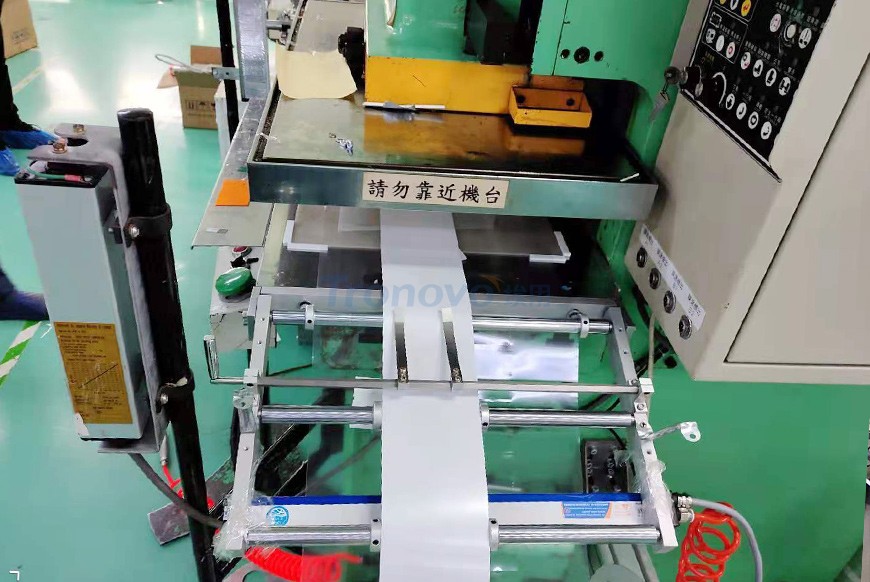

Customers to buy a good ion bar TR8630, and in the exit above the installation of the ion bar, we received a call from the customer feedback “static electricity is not eliminated cleanly”, the phenomenon is: the product has a static adsorption of the edges of the storage box, the sheet can not be sorted out, straighten out. We came to the scene with a static meter checking found that the reverse side of the film there is a very high level of static electricity (ion bar to the front of the static electricity has been removed cleanly, but the bottom of the static electricity did not get rid of).

The problem was solved by installing another ion bar at the separation point of the release film (due to space constraints for installation, the ion bar was vented to increase the distance of static electricity removal).