Concern

Small injection molded parts cannot be detached from the mold due to static electricity and the product is contaminated by dust.

prescription

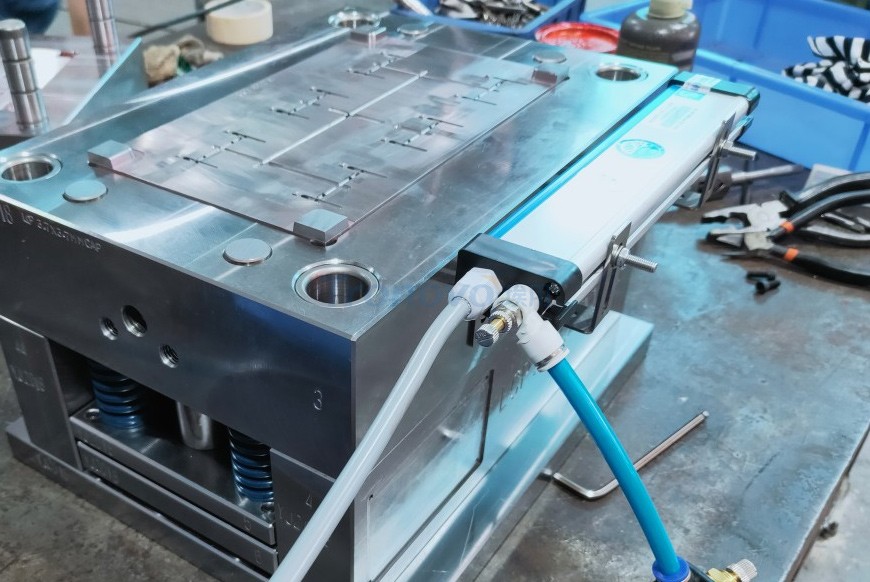

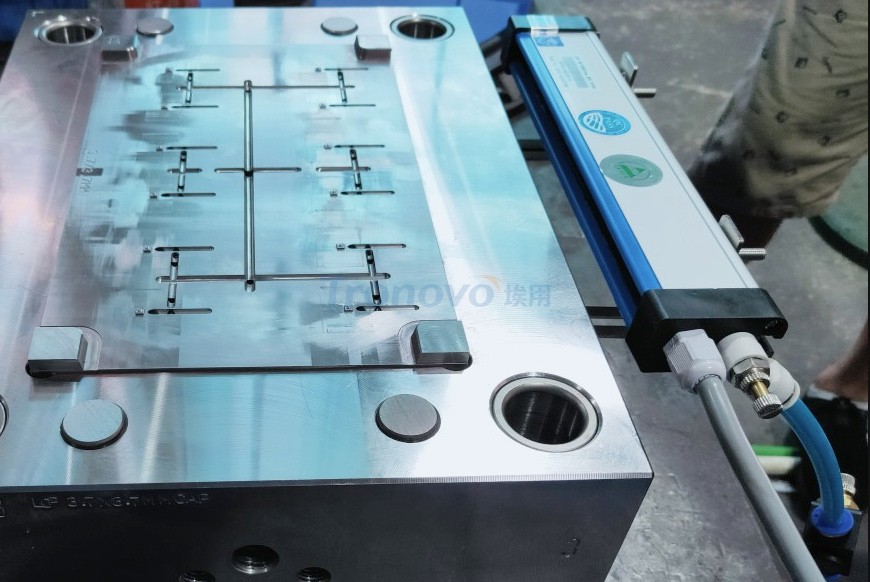

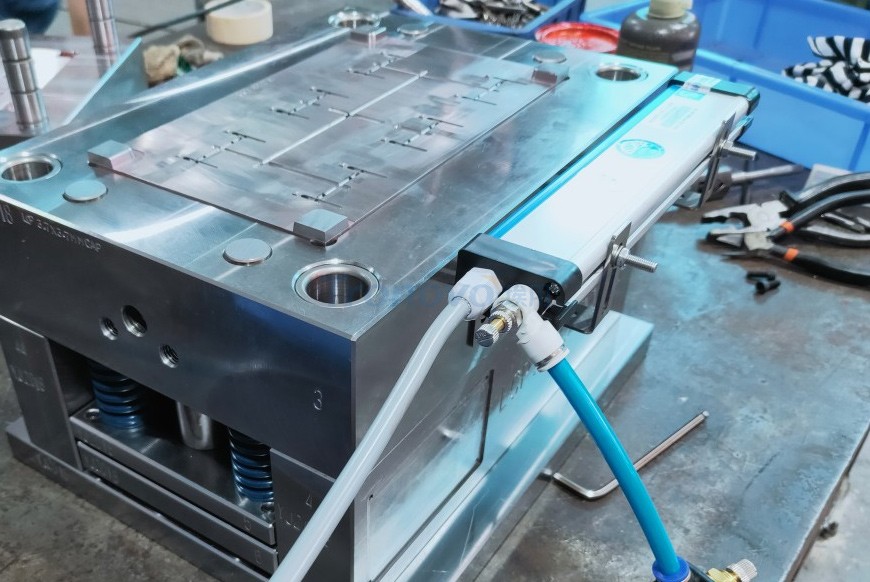

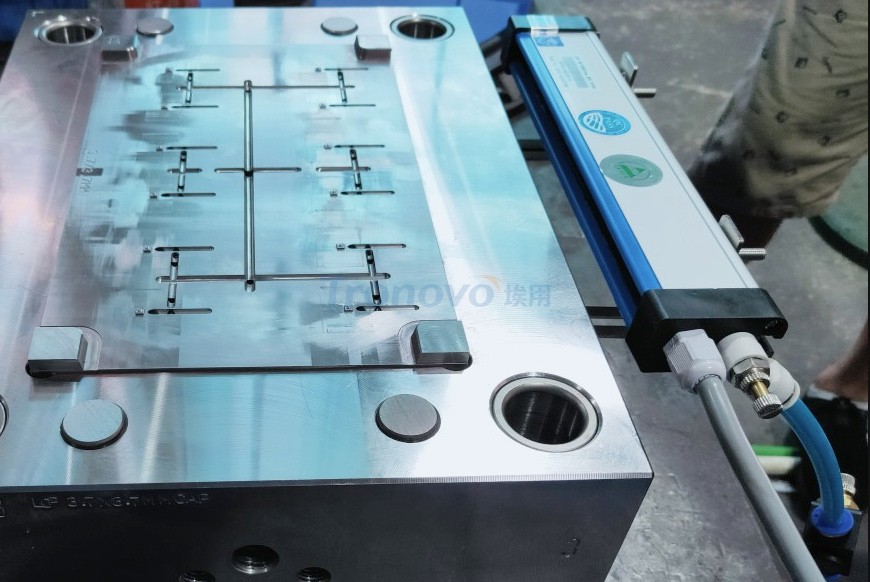

1. Installation of Tronovo electrostatic precipitator on top of the mold, electrostatic precipitator TR8630, 1pc.

2. Connect to clean, dry compressed air and blow ionized air downward

3. According to the size of the mold, you need to adjust the appropriate air pressure.

Plastic components are very susceptible to electrostatic charge as they are ejected from the open mold of an injection molding machine, which can lead to dust contamination of the product. To prevent this, static bars are placed above the open mold to provide a stream of ionized air that is blown toward the product to eliminate the static charge on the product, thus avoiding subsequent contamination problems.

After the opening mold is detached, the large injection parts are placed by the robot arm on a conveyor belt in motion. This conveyor belt can also be fitted with a TR8630 ionizing air bar in order to prevent dust attraction.