What are the possible reasons for the ineffectiveness of the static elimination device on the shaker?

When the static elimination device on the vibration plate is still ineffective after treatment, it may be manifested in the following aspects:

1. Material still charged:After the electrostatic elimination device treatment, the material still carries static electricity, which may lead to the material in the vibration plate can not be separated or fed properly.

2. The feeding speed is affected:The static electricity problem is not effectively solved, which may lead to mutual adsorption or bonding of materials in the feeding process, thus reducing the feeding speed and affecting the production efficiency.

3. Deterioration of feeding quality: Static electricity may lead to the material in the feeding process, such as the position of the offset, arrangement of confusion and other problems, thus affecting the quality of feeding.

4. Decrease in equipment stability:When static electricity is a serious problem, it may affect the stability of the vibrating plate, resulting in equipment failureor downtime.

There may be a variety of reasons why the static eliminator on the shaker is not working well, here are some possible reasons:

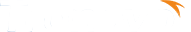

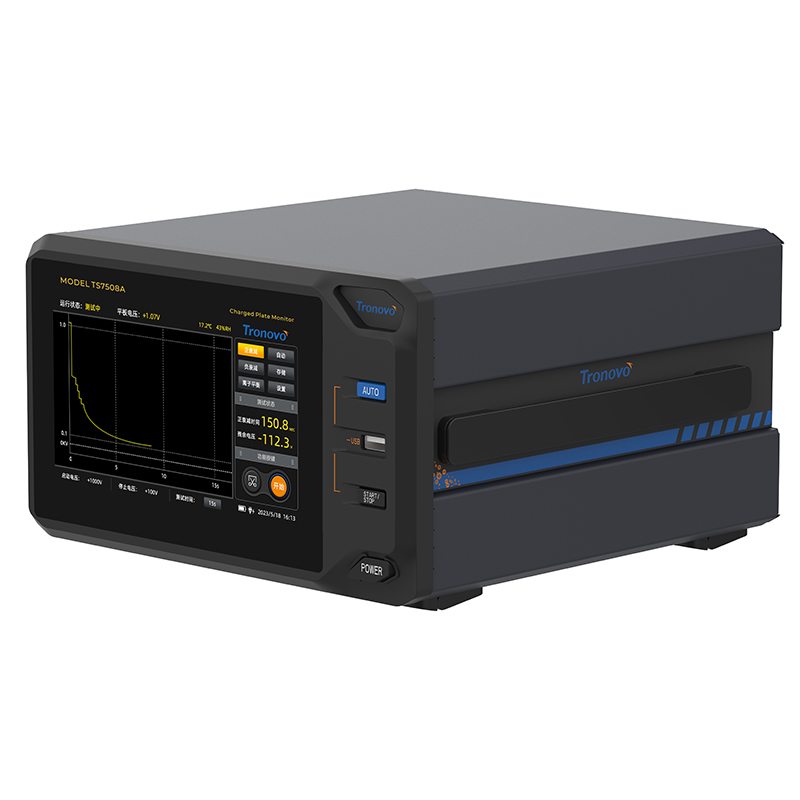

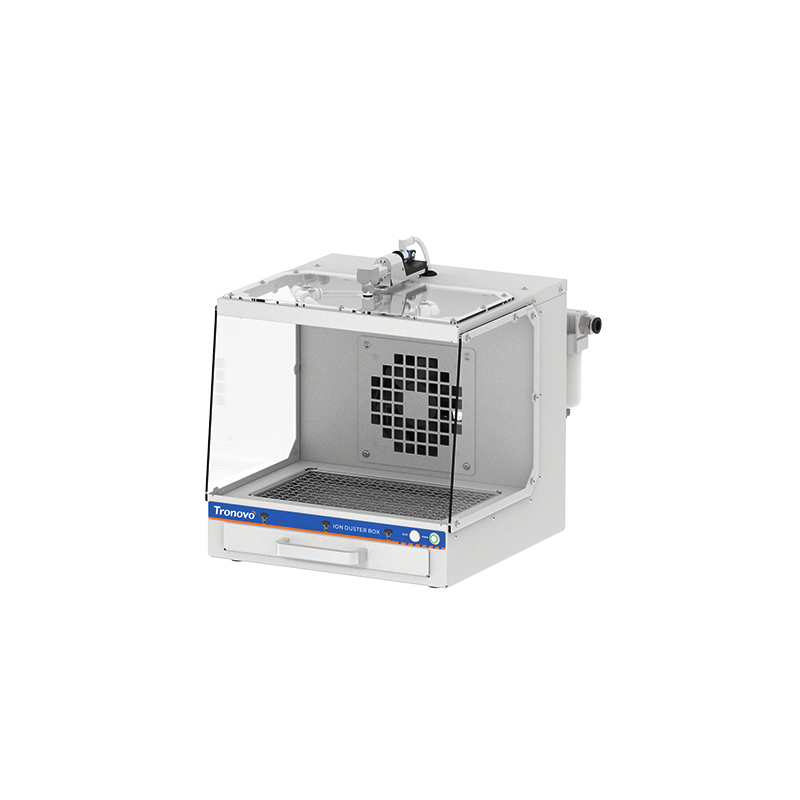

1. Improper selection of static eliminator:Different materials and operating conditions may require different types of electrostatic eliminators. For example, what is the difference between the coverage of the static eliminator, the speed of static removal, the ionic balance, whether to blow air or not, whether it is better to blow air or blow air, whether to install ion rods or to install ion nozzles or ion blowers, and what is the difference between the AC technology/high-frequency AC technology/DC technology/pulse AC technology? If the device is not properly selected, it may not be able to effectively neutralize static electricity or effectively remove static electricity.

2. Improperly set parameters of the electrostatic elimination device:Static elimination devices usually need to be adjusted and optimized according to the specific working environment. If the parameters are not set properly, such as ionized air volume, pulse frequency, pulse width, etc., it may affect its effect of eliminating static electricity.

3. Improper maintenance of the device: Electrostatic elimination devices require regular cleaning and maintenance to ensure that they work properly. If cleaning is not performed for a long period of time, the performance of the ion generator may deteriorate, thus affecting the static elimination effect.

4. Environmental factors:Factors such as humidity and temperature in the environment may affect the effectiveness of static elimination devices. For example, low humidity may cause static problems to become more severe, while high temperatures may affect the performance of the device.

5. Material characteristics: The conductivity, surface roughness and other characteristics of the material can also affect the generation and elimination of static electricity. Certain materials may be more susceptible to static electricity or more sensitive to static electricity, which may lead to ineffective static elimination devices.

6. Improper location, height or mounting of the device: Where and how the static elimination device is installed can also affect its effectiveness. If the device is not installed in the proper location, it may not effectively cover the entire vibratory plate area, or the ionized air may not be evenly distributed to the material surface.

To address these possible causes, the following measures can be taken to improve the effectiveness of the static elimination device:

● According to the material characteristics and working environment to choose the appropriate static elimination device.

● Carefully adjust and optimize the parameter settings of the unit.

● Regular cleaning and maintenance of the unit.

● Control factors such as humidity and temperature in the work environment.

● Improve the material handling process to reduce the generation of static electricity.

● Re-evaluate and adjust where and how the unit is mounted.

In summary, for the problem of poor effect of electrostatic elimination device on the vibrating plate, it is necessary to comprehensively consider a number of factors, and take appropriate measures to improve and optimize.