How to deal with the problem of static electricity in the vibrating disk feeder?

Vibrating disk feeder is widely used in electronics, medical, pharmaceutical and other automated assembly industry, but in the vibration process, the mutual friction between the devices is easy to generate static electricity, resulting in feeding disk rotating feed can not normal feeding, and even the products will be adsorbed each other adhesion, or the device and feeding Even the products will be adsorbed and bonded with each other, or the devices will be adsorbed with the bottom surface of the feeding disk, which will affect the speed and quality of feeding, and then reduce the production efficiency.

In order to deal with the static problem of the vibratory tray feeder, here are some suggested solutions that Eyre has used:

1、Increase the conductivity of the vibrating plate: By using conductive materials or coating conductive coating on the vibrating plate, the conductivity of the vibrating plate is enhanced. In this way, when the material and the vibrating plate friction, electrostatic charges can be smoothly through the vibrating plate conductive materials or coatings to guide away, reducing the phenomenon of material charged.

2、Increase air humidity: Increasing the humidity in the environment can effectively reduce the generation of static electricity. Humidification equipment can be used to maintain a certain level of humidity around the vibratory plate loader to reduce static electricity.

3、Spraying antistatic agent to the material: the use of antistatic agent can change the state of charge on the surface of the material to reduce the generation of static electricity. According to the specific characteristics of the material to choose the appropriate antistatic agent, by spraying the material in the way of antistatic agent, the formation of a layer of conductive film on the surface of the material to reduce the phenomenon of material charged.

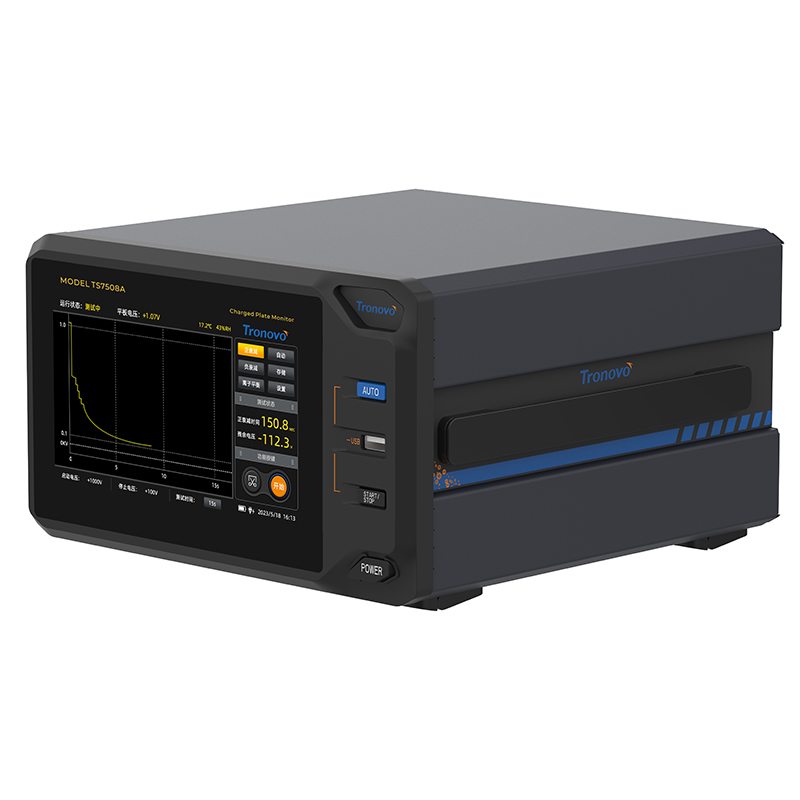

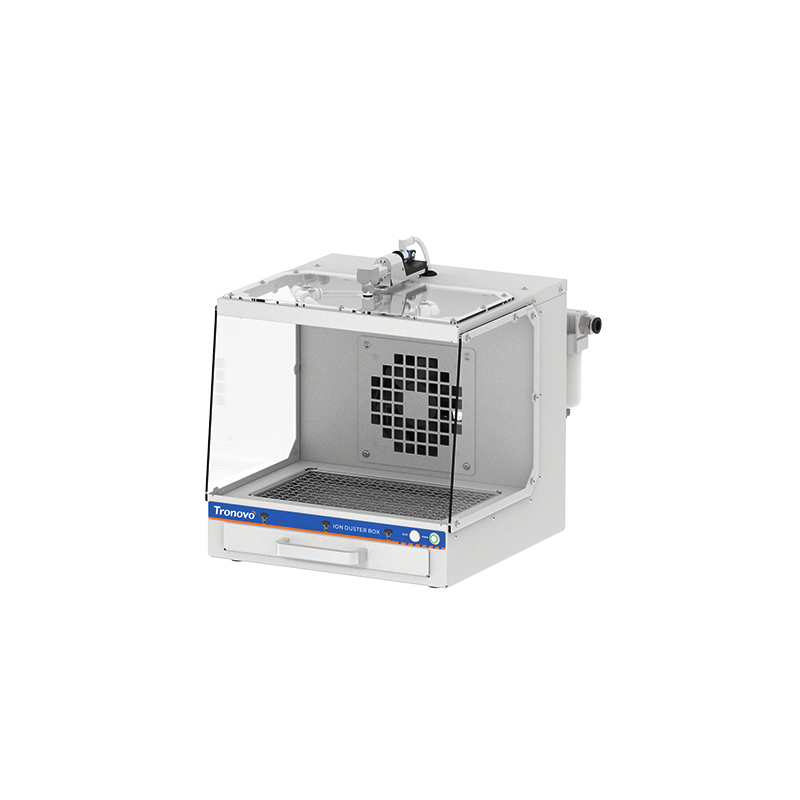

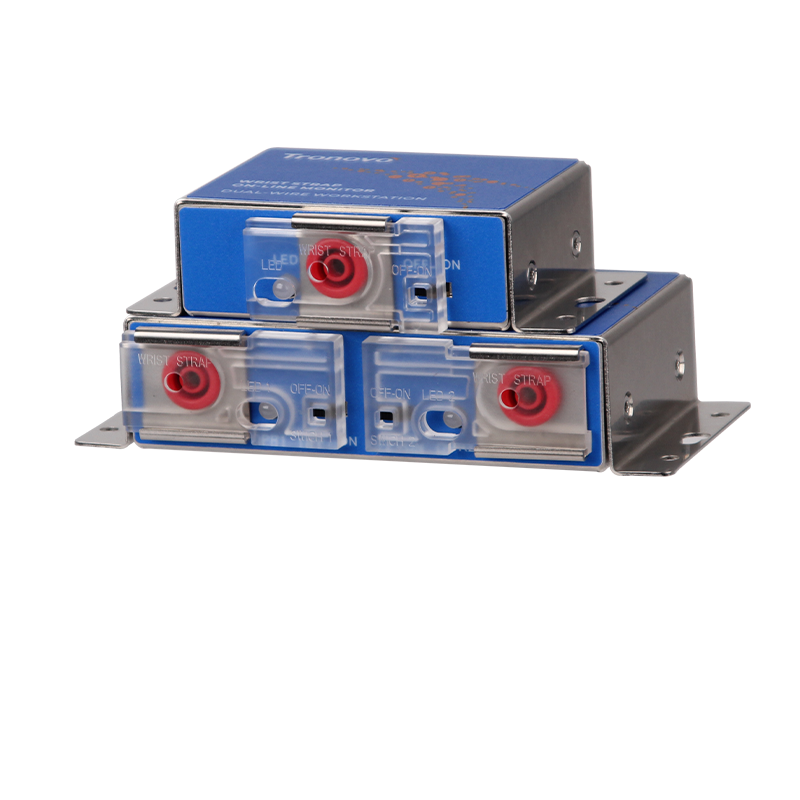

4、Installation of Ion Fans, Static Elimination Rods or Ion Nozzles: Installation of Static Elimination Rods or Ion Nozzles at specific locations on the vibratory plate, these devices can generate a large amount of ionic wind to neutralize static electricity and reduce the accumulation of static electricity.

5、Connect the ground wire to the vibrating plate: Through the ground wire, the static charge generated on the vibrating plate can be channeled to the earth to achieve the purpose of eliminating static electricity.

6、 Above if exclude static electricity problems, you can further improve the product design, such as: adjust the vibration frequency, reduce friction or contact area, increase the blowing device.

To summarize, dealing with the static electricity problem of vibrating plate feeder needs to start from many aspects, and choose the appropriate solution in combination with the actual situation to ensure the smooth progress of production. At the same time, in order to ensure the safety of operators, should ensure that all operations are in line with the relevant safety regulations and standards.