Electronic industry curve divider static elimination applications

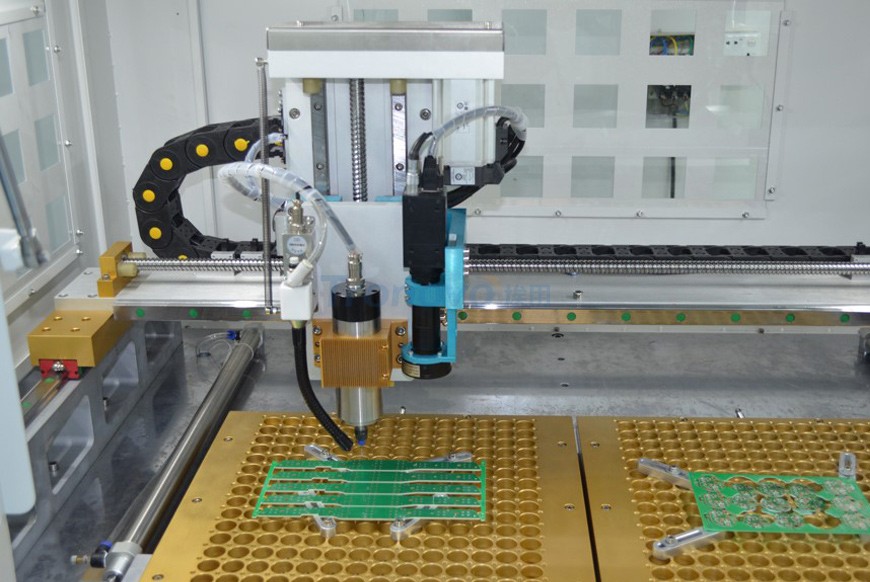

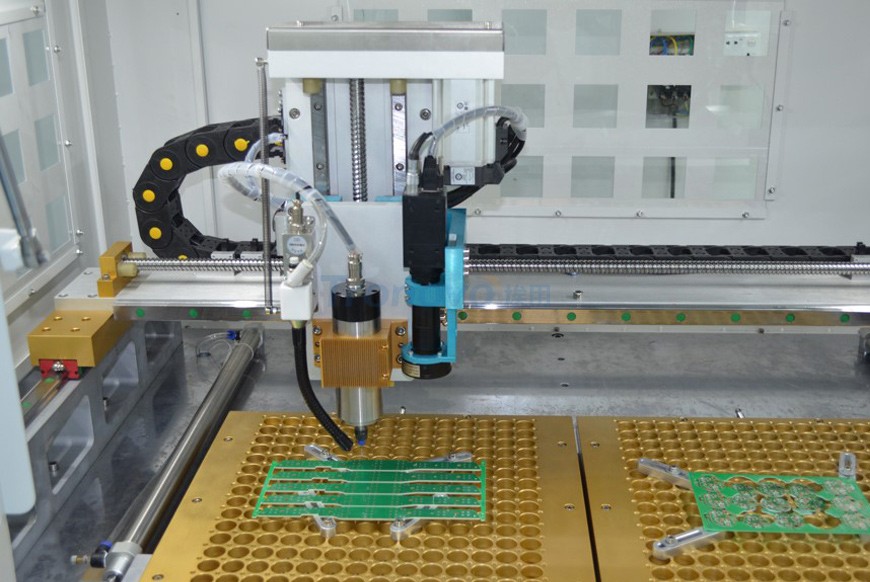

Automatic Curve Splitter is a device that utilizes a high-speed rotary milling cutter to split multiple consecutive PCBs according to the programmed path. Widely used in digital, communication, lighting and other fields. Improve the manual breaking, V-CUT, stamping and other ways of dividing boards flawless artifacts, improve the quality and reduce the scrap.

concern

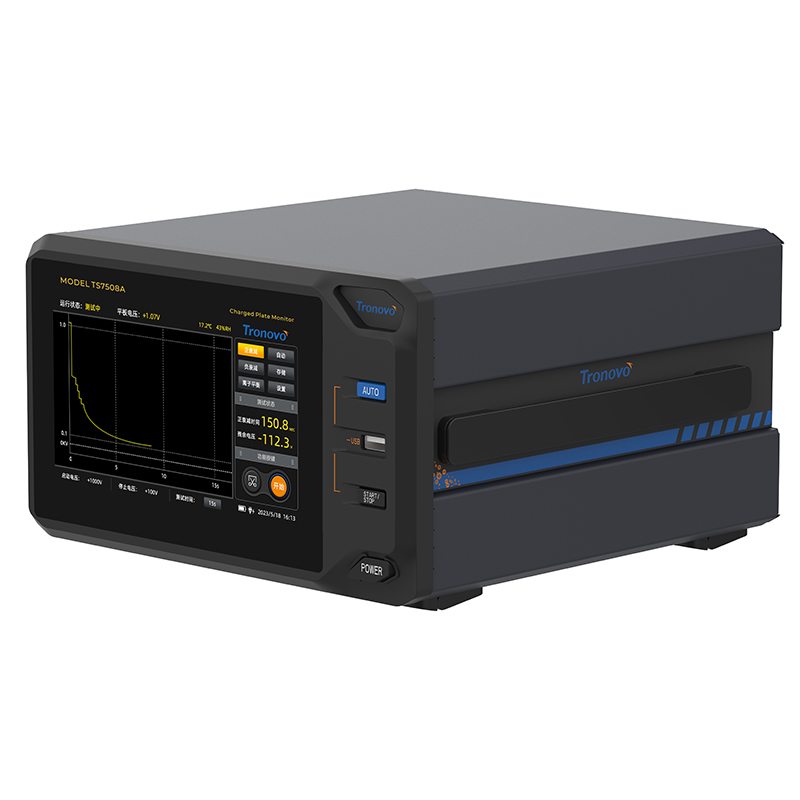

PCBA slitting process milling cutter high-speed operation will produce a lot of static electricity and dust, has been installed strong dust-absorbing filtration device, the process needs to be sprayed with three anti-painting, but how to solve the problem of clean dust after cutting, has been plagued by, summarize the scene of the customer's problems are mainly the following points:

1. A large amount of dust adheres to the cutter head.

2. There is more dust on the circuit boards, which cannot be blown off by ordinary air guns.

3. Eliminate the existing manual dusting and cleaning (the customer was advised to use an ion gun but refused, hoping to save labor).

4. To avoid damage to parts due to static electricity.

prescription

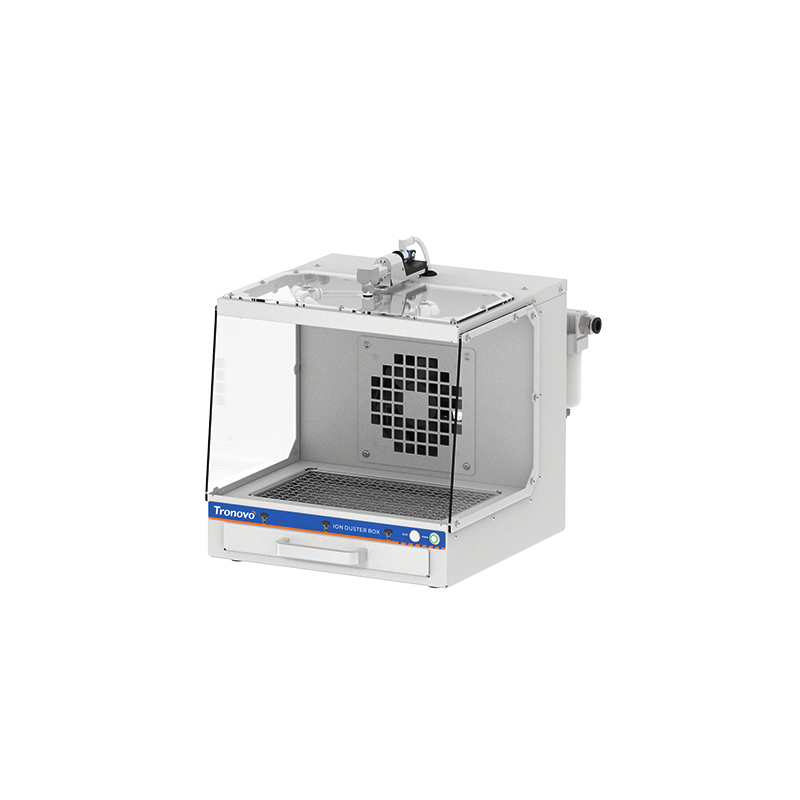

1. When cutting the spindle front section installed with TR8385 hose nozzle ion nozzle, generating ion gas flow constantly in the milling cutter around the blowing, reduce the high-speed spindle cutting static electricity, can avoid parts due to static electricity caused by damage.

2. Install 2 Eyre TR8660 ion rods above the sliding platform to separate the dust from the electric panel board and improve the vacuuming effect.

Acceptance:

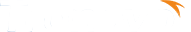

The use of ion plate instrument in the cutter head below and above the jig, respectively, to test the ion balance and de-static speed, are to meet the electronics industry standard ± 35V requirements.