Case of electrostatic precipitator for lining powder spreading machine

Powder spreading machine adapted to all kinds of non-woven fabrics, garment lining fabrics and other fabrics for the spreading of hot melt adhesive powder into the oven melting penetrate into the lining fabrics after rapid cooling directly rolled, through the PE, HDPE, LDPE, PA, EVA, EVAL, PES and other hot melt adhesive powder can be realized by various types of bonded lining lining fabrics powder spreading the desired effect.

Fabric Printing Powder Spreading Machine is mainly composed of powder spreading device, transmission mechanism and residual powder recycling device. The excess gold and silver powder on the fabric passes through the powder suction port, which can recycle and reuse the excess powder. If the customer's interlining fabric has a lot of static electricity, a lot of powder will be trapped in the interlining fabric after processing, resulting in poor quality and causing customer complaints.

Question:

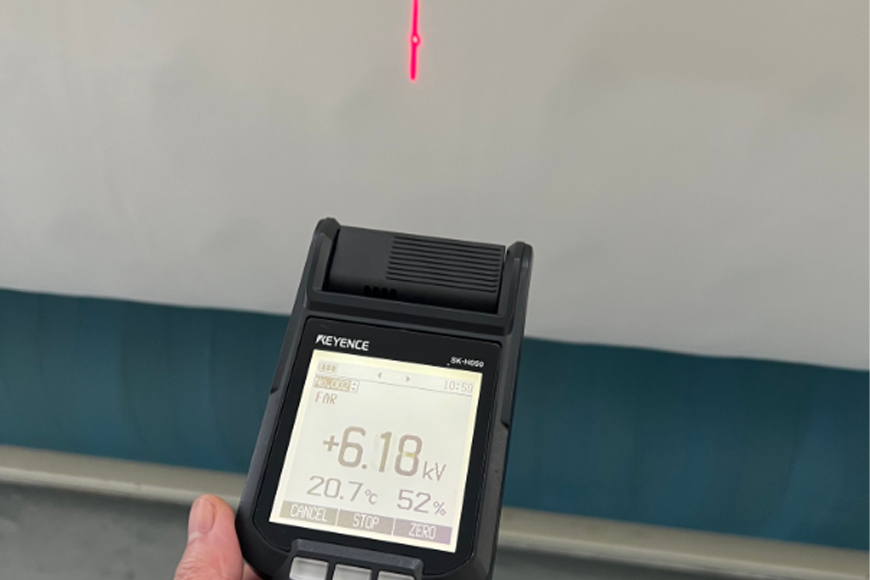

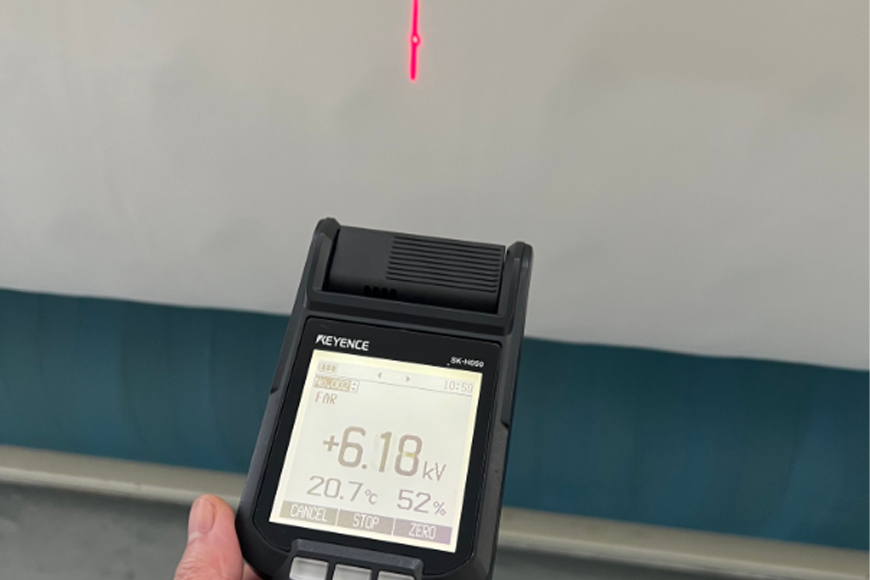

The fabric of the product is not anti-static fabric, the measured resistance value of the instrument is greater than 10 to the 12th power, the measured static voltage is as high as +6.18KV, and the lining fabric is seriously powdered after the actual measurement on the machine.

Solution:

1、Install Tronovo static elimination rods at the place where the lining fabrics are put on the rolls, and then sprinkle the powder after removing static electricity from the lining fabrics first.

2、in the powder suction mouth, install Tronovo with static elimination rod, the first dust in addition to static electricity, to remove the static electricity adsorption.

3, such as suction powder is not clean, you can then install a static elimination bar, connected to clean compressed air, its strong ionized air flow on the surface of the lining of the powder and dust foreign matter to do further cleaning.

Keywords: suzhou static eliminator, suzhou de-static, ion wind knife, ion air knife, ion rod, industrial static eliminator, suzhou ion wind rod, de-static rod, static eliminator, interlining static eliminator, powder spreading machine de-static, fabric static eliminator, powder spraying machine de-static, static elimination equipment, calender static eliminator, stamping machine static eliminator, warping machine static eliminator, winding machine static elimination, Static electricity elimination for stenter fixing