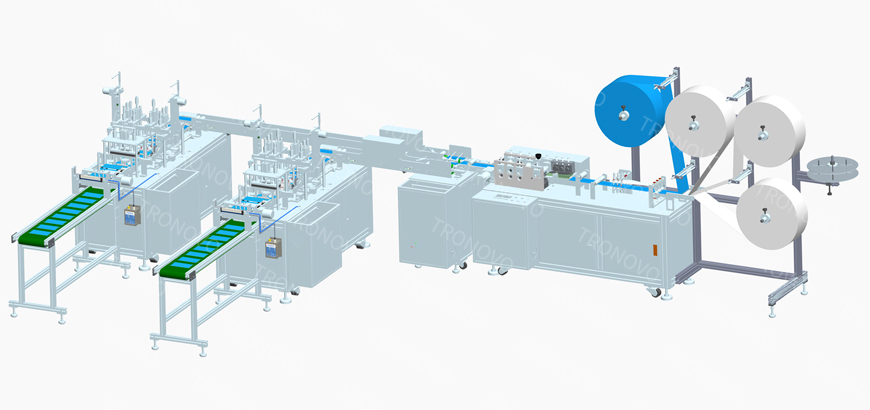

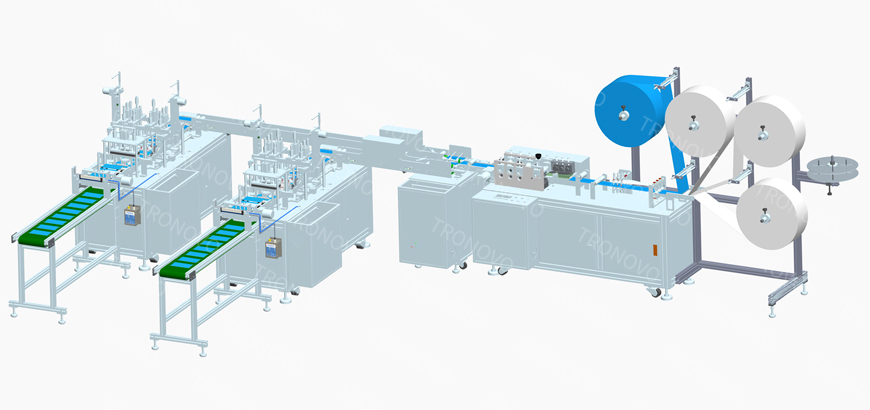

Mask machine static electricity elimination application case

Concern

1. Static electricity flies after the plane mask is pressed, and it is not easy to organize.

2. Low productivity due to drift in automated production transfer stacks

3. The finished masks are not neatly stacked and there are cases of electrocution during packing

4. When the mask is spraying code, the spraying dock adsorbs the lint because of static electricity.

5. Dust will be adsorbed during the production of masks, high defective rate

Prescription

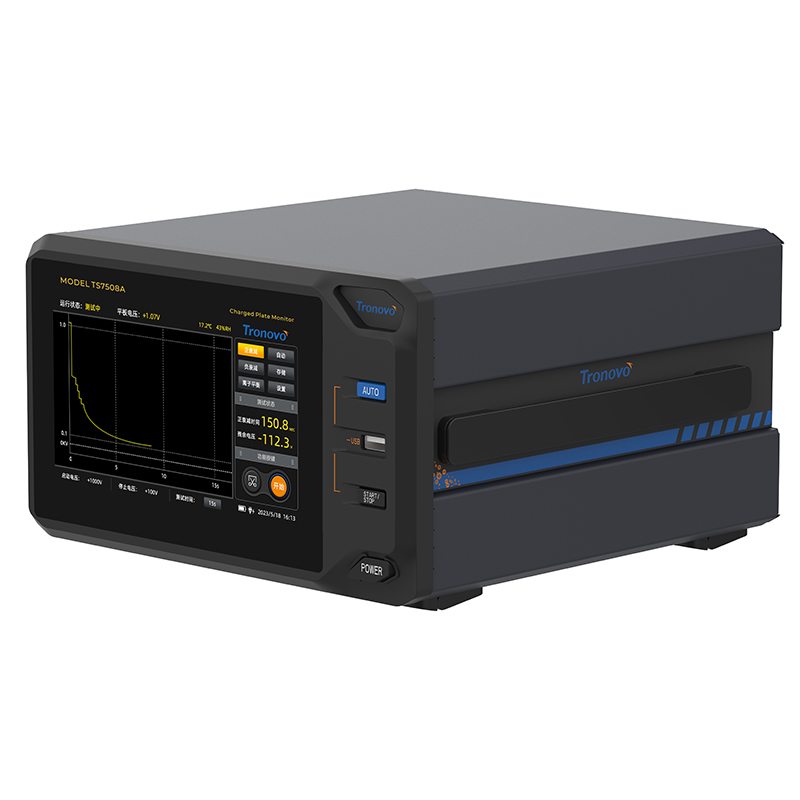

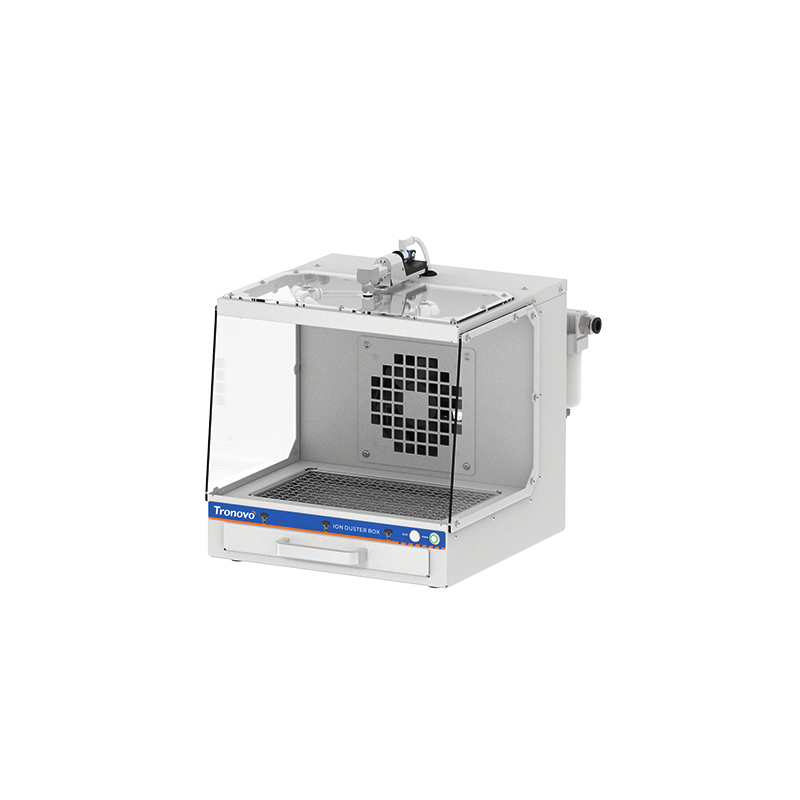

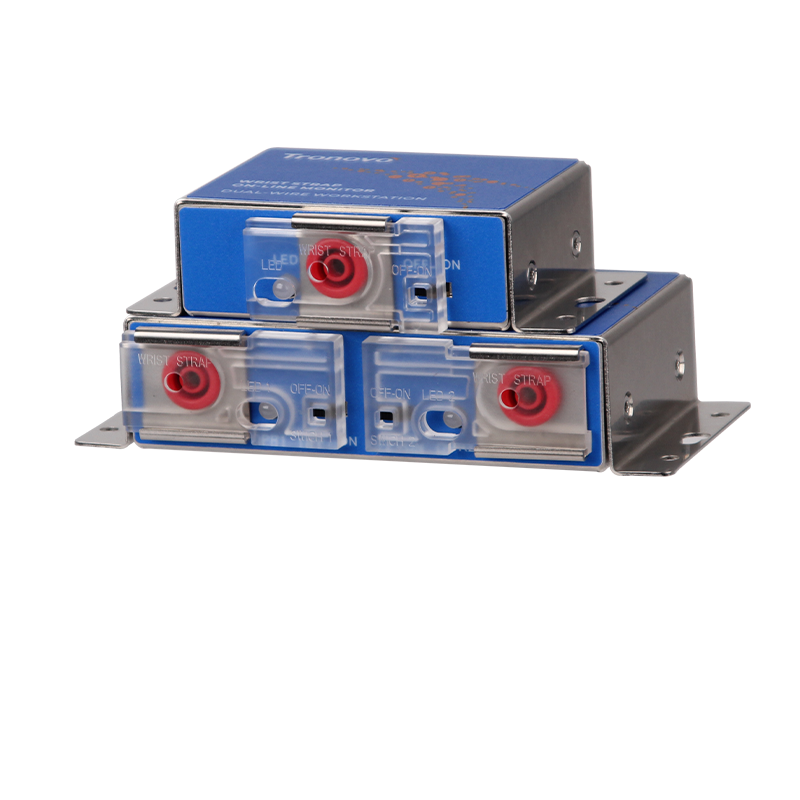

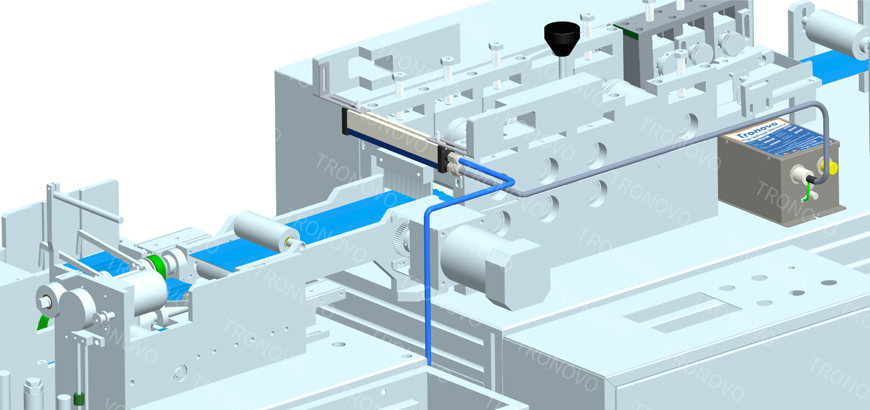

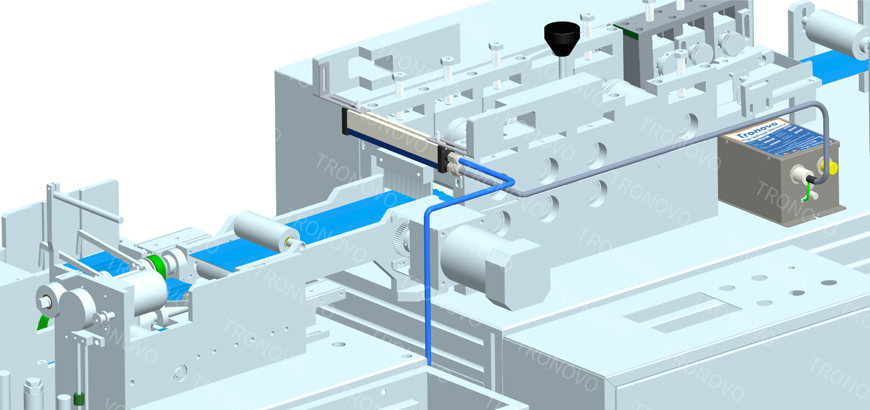

1. Install a Tronovo TR8610 or TR8630 static eliminator bar at the exit of the mask punching machine.

2. Ear band fusion machine is recommended to be generally placed in the finished product discharge section

3. Static elimination rod and ear band distance of 5cm, high-speed machine is recommended to use TR8630 high-power type, can be appropriate ventilation effect is better.

Many customers are worried that the meltblown cloth inside the mask has static electricity, and whether the use of static eliminator in production has an effect on the quality of the mask, this worry is not necessary.

The production of masks is automatically stacked neatly at the product discharge position with the help of static eliminator, saving time and labor for the next process of ear band welding.

In addition, when the mask is molded and folded, it will also be folded unevenly due to static electricity, thus greatly increasing the workload and affecting the productivity of the mask machine.