Glass production line de-static dust removal case

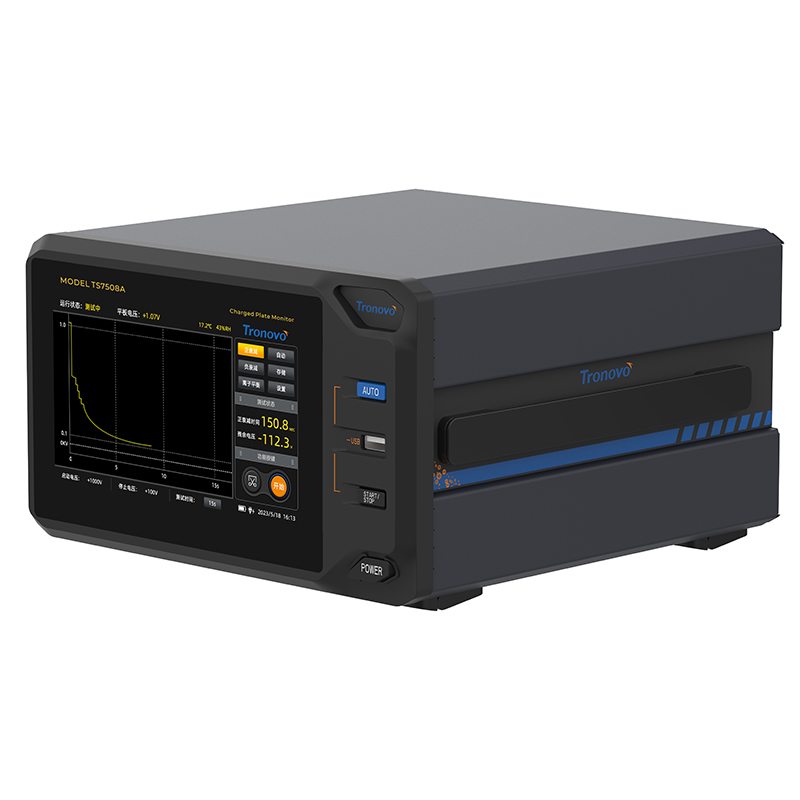

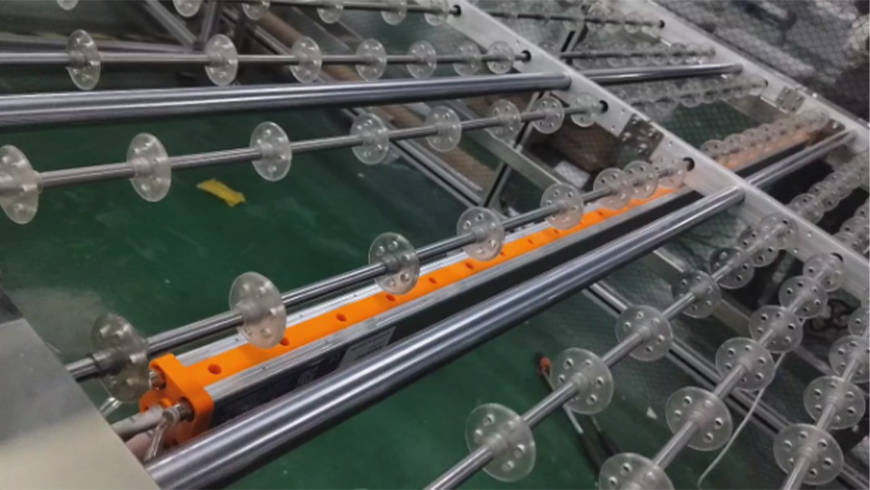

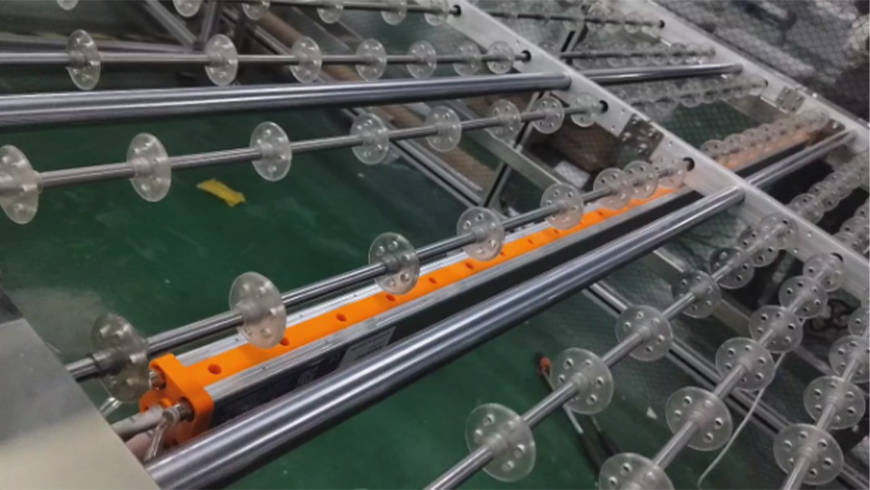

In the glass production line, the need to dust the glass to ensure the quality of glass products, and the realization of the core of the dust removal work is to remove the static electricity, ion wind rod, also known as ion wind knife dust removal effect is good, easy to install, is widely used in the glass production industry, the two electrostatic precipitators were fixed in the upper and bottom of the conveying device, you can synchronize the two surfaces of the glass electrostatic dust removal work to improve the efficiency of work. Work efficiency.

Question:

During the production process of glass, there is a high level of static electricity, which adsorbs dust, hair and other small particles of foreign matter and affects the quality.

Solution:

1, the inlet above and below the installation of Tronovo with electrostatic removal function of the ion wind knife (from the height of the glass 8 ~ 10 cm), in addition to electrostatic removal of dust at the same time.

2, blowing type ion rod structure, connected to clean compressed air, its strong ion wind to remove static electricity and dust on the surface of the object foreign matter.

3、Ion bar de-static function, completely eliminate static electricity to reduce secondary pollution.

Keywords: Eyewear, Eyewear static electricity, ion air knife, ion air knife, ion rod, ion air rod, static eliminator, eliminate glass static electricity, glass static elimination, glass substrate static elimination device, glass on-line de-static device, glass surface static elimination device, glass sliding static elimination device