Efficient solution to the static electricity problem of the vibration disk, customized electrostatic removal scheme to help stabilize production.

Project Background:

In the process of automatic conveying of electronic components, hardware and other precision materials, the vibration plate is widely used because of its efficient sorting and feeding ability. However, the continuous friction between the material and the track during the vibration process is easy to generate a large amount of static electricity, resulting in parts adsorption, stacking, blocking the outlet, and even causing component breakdown, resulting in production interruption and quality hazards.

Solution:

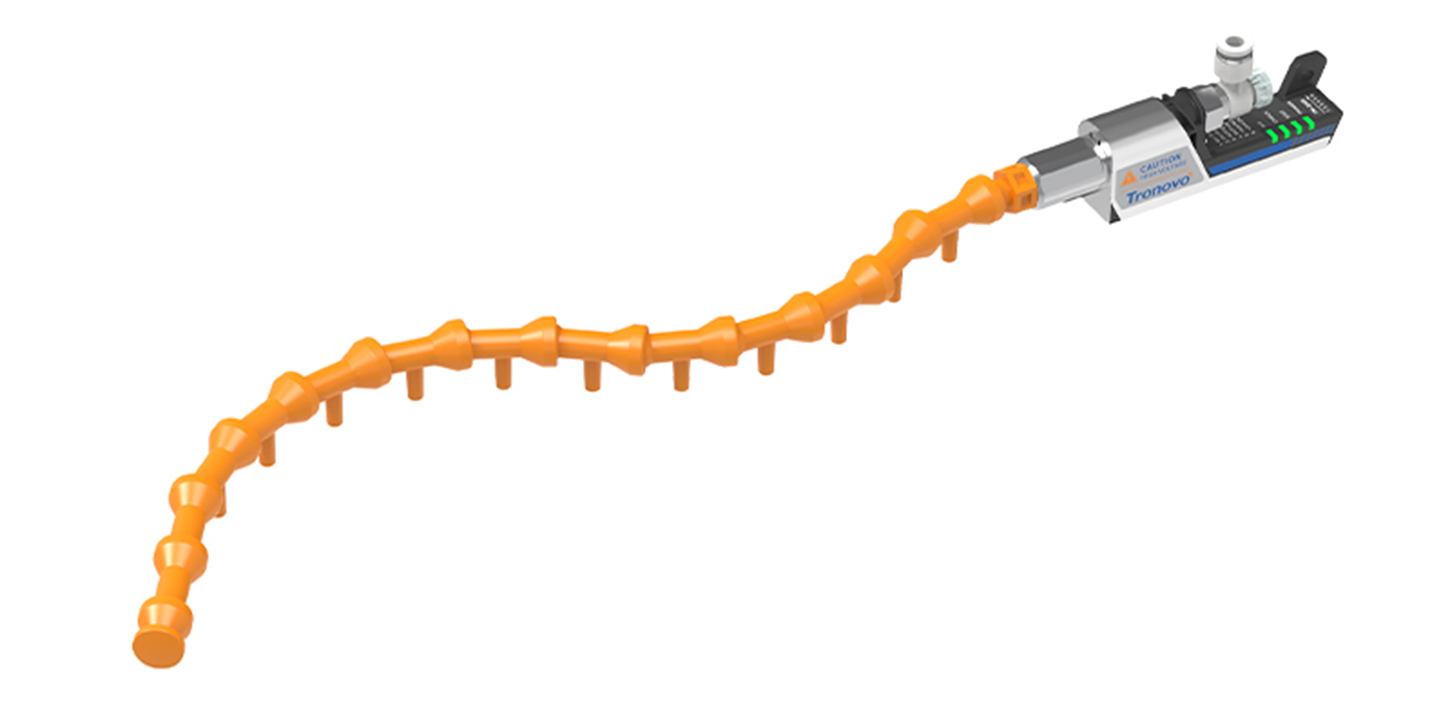

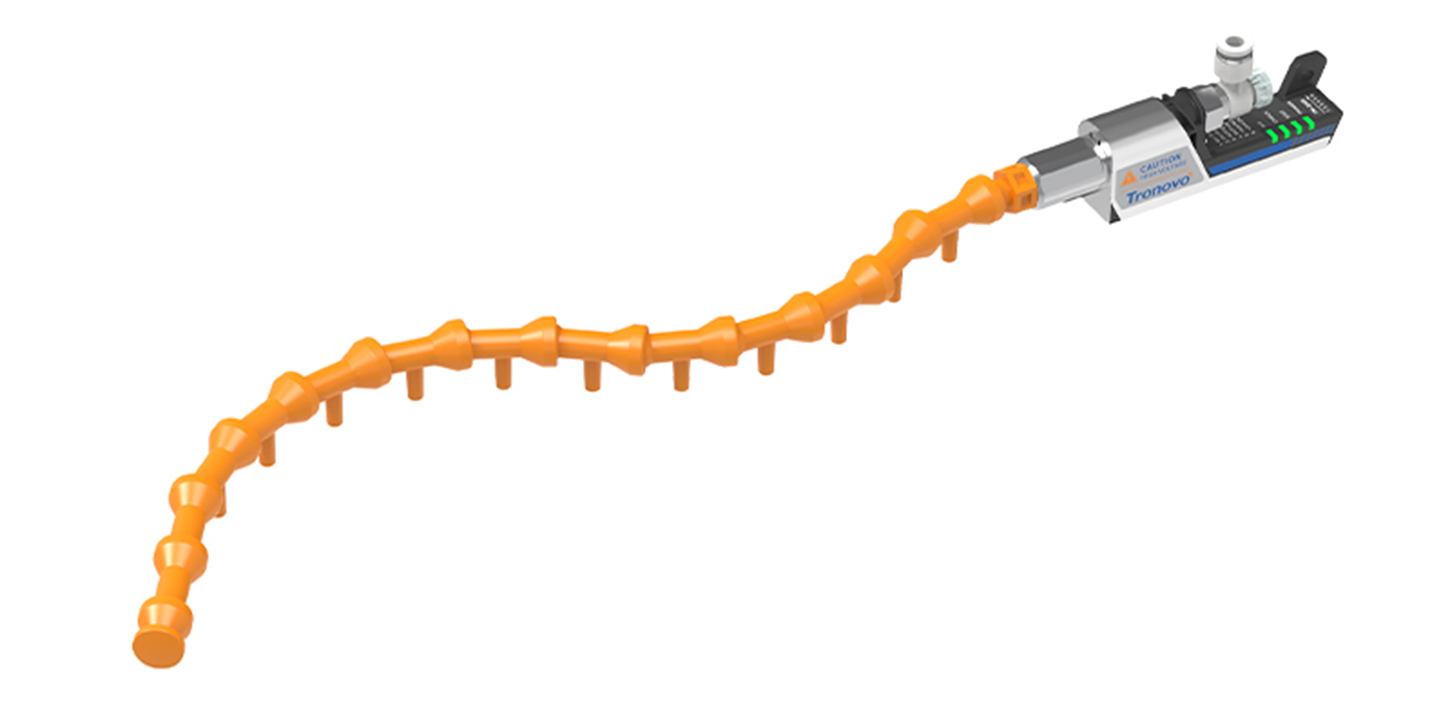

In response to these 1 pain points, we have introduced a customized static elimination solution specially designed for vibration disks. The scheme realizes full coverage of ions airflow by accurately arranging ionizer air nozzles that can be adjusted in multiple ways in key friction areas such as the inside of the vibrating disk and the discharge port, and matching flexible bamboo tubes. The neutralization ionizing beam generated by the electrostatic eliminator can quickly eliminate the positive and negative electrostatic charges on the surface of the material, and eliminate the jamming and disorder caused by electrostatic adsorption.

Core advantages:

Compared with the traditional static elimination method, the ion nozzle has the advantages of strong directivity, rapid response and flexible installation, and is suitable for vibration disk systems of different sizes and structures. Effectively improve the consistency of feeding and production efficiency, especially suitable for the production of high-precision components sensitive to static electricity. Fundamentally reduce the frequency of downtime, for enterprises to achieve stable, continuous automated production to provide a reliable guarantee.