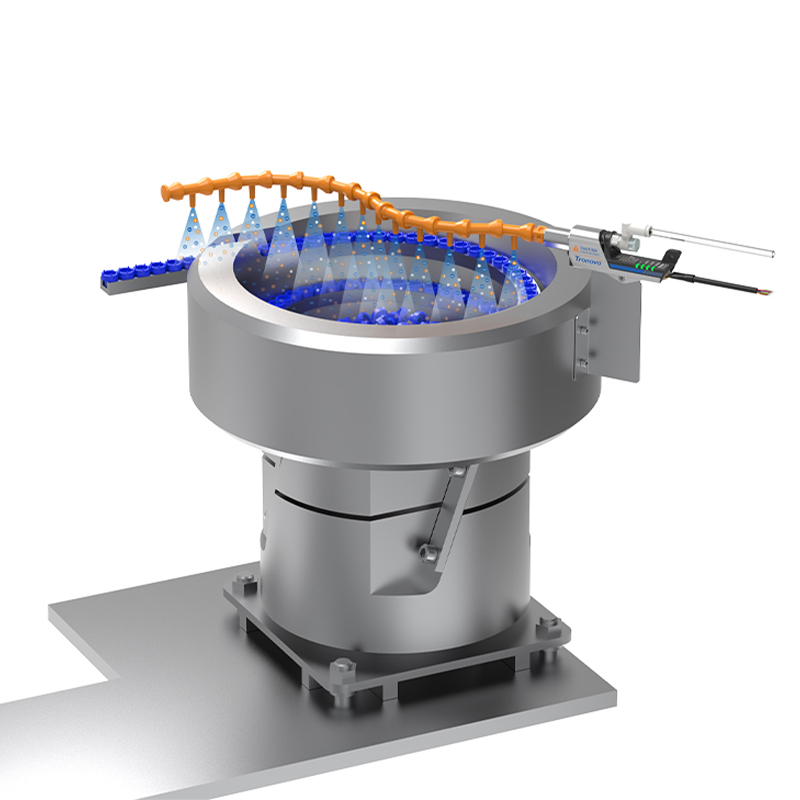

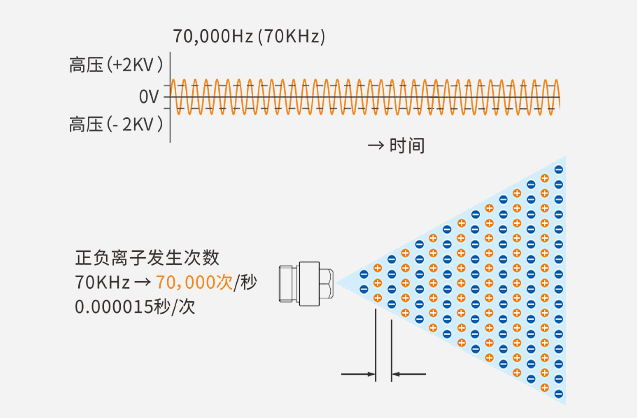

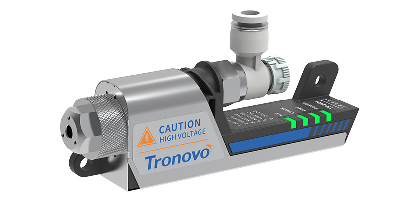

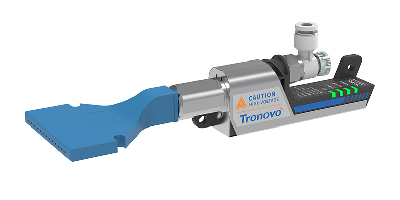

Ultra-compact static elimination nozzles, specially designed for small spaces, can precisely target the workpiece to remove dust and pollutants, and eliminate static electricity efficiently at the same time. Equipped with a wide range of nozzles, suitable for a variety of industrial cleaning scenarios to meet the needs of different applications. Adopting high-frequency AC technology, the ionic balance is extremely stable and is not affected by supply air pressure or installation distance, so there is no need for tedious debugging after installation, which greatly improves operational efficiency. Applicable to electronic components, precision instruments and other fine cleaning scenarios, efficiently solving the problem of electrostatic adsorption, helping to maintain the cleanliness of workpieces and production stability.

Features:

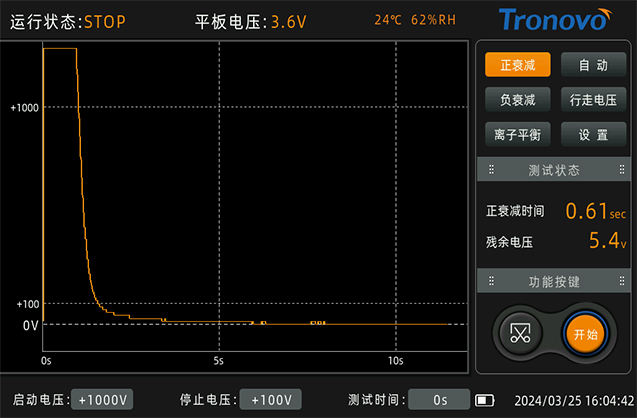

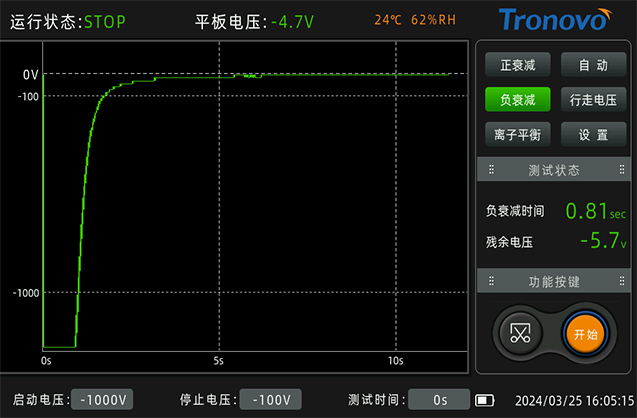

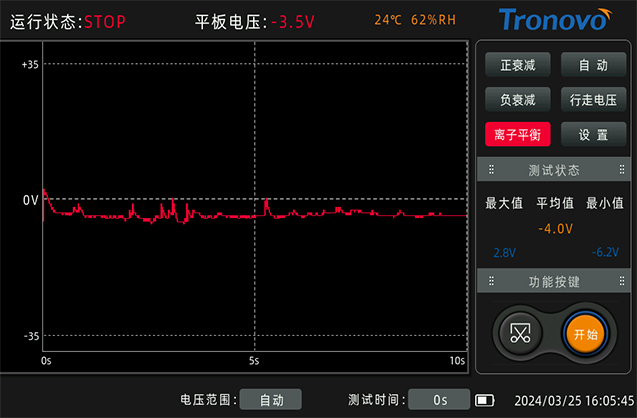

• High-frequency AC ionisation technology achieves a very stable ion balance and more reliable static elimination.

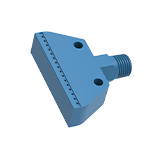

• Extremely small static eliminator design, compact structure can be easily assembled inside the equipment, saving installation space.

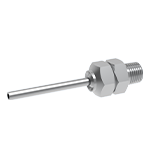

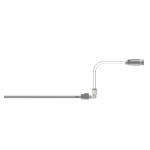

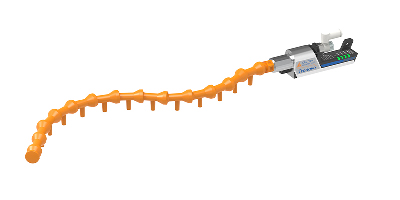

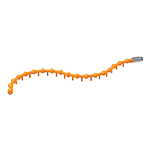

• A wide range of supporting static elimination nozzles can be selected according to the actual use of the different types of suitable for a variety of scenarios.

• Equipped with signal input and output control functions, automated on-line through IO communication, enhancing production efficiency. Enhance production efficiency

• Reassuring safety design, 24V DC safety power supply, no need for high-voltage cables, to ensure safe operation

• With operating status indicator, real-time display of equipment operating status, to facilitate timely monitoring

• Easy maintenance, the ion needle can be easily removed and cleaned, reducing maintenance costs

• Default length of the nozzle is 40cm, including 13 nozzles, and supports the shortening or lengthening of the nozzle according to the needs of the flexibility.