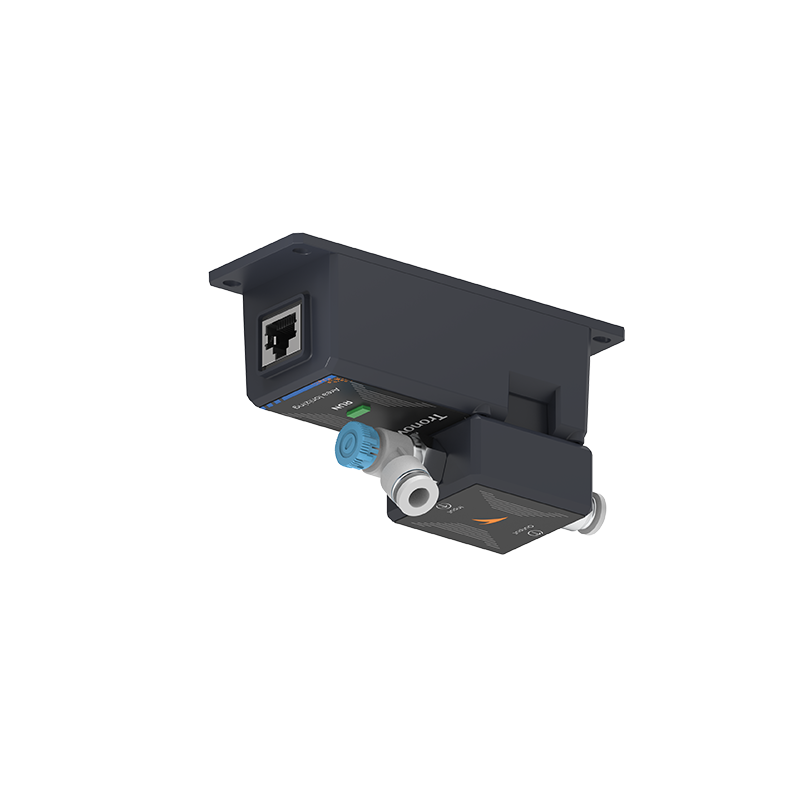

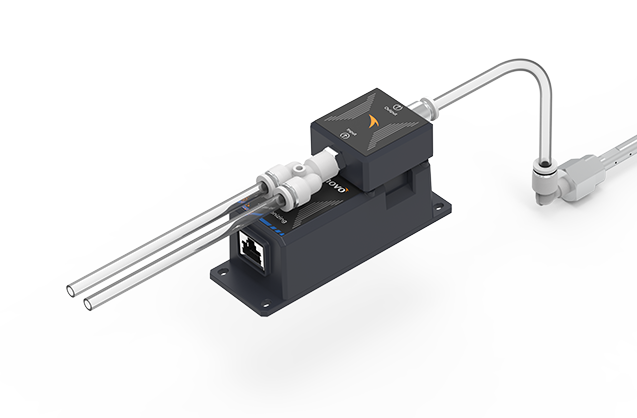

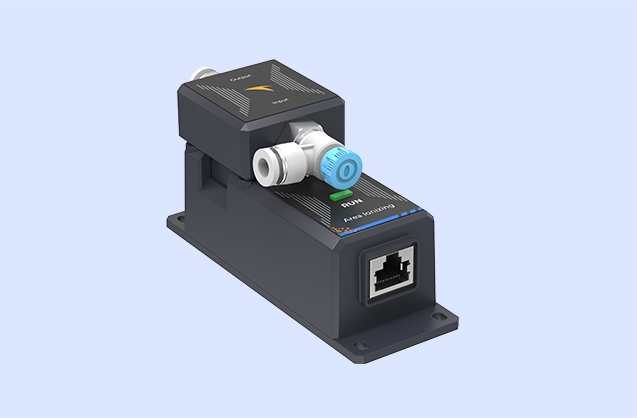

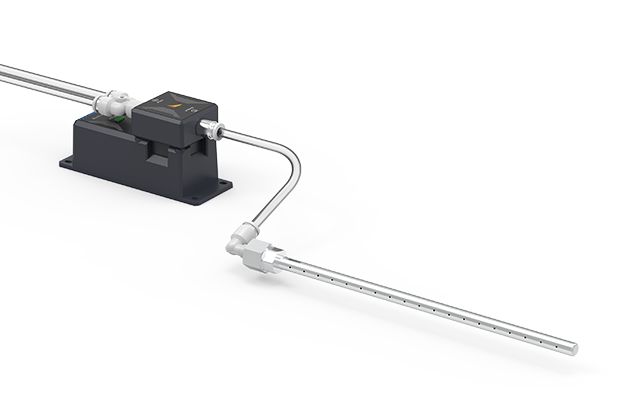

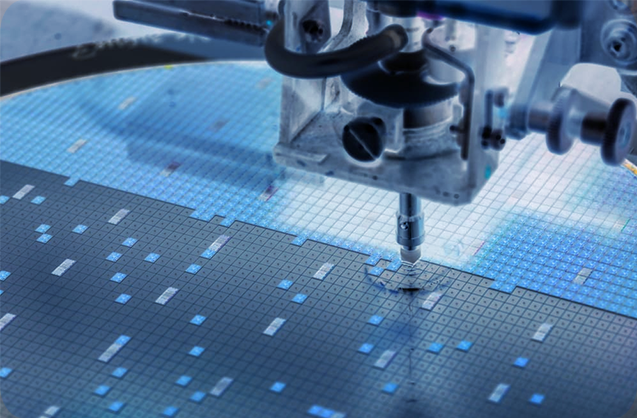

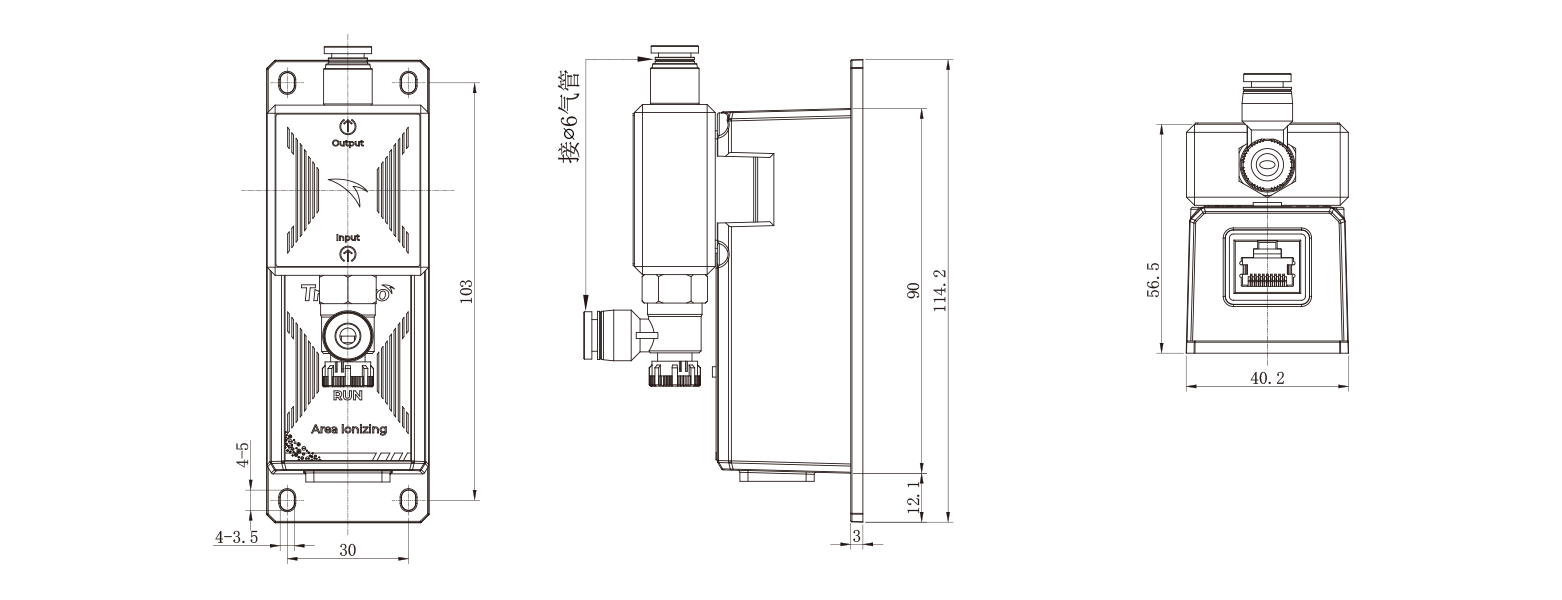

The transmission-type In-tool Ionizer is specially designed to solve static electrostatic issues in hard to reach or enclosed work areas, and is widely used in high-precision manufacturing industries such as semiconductors, flat panel displays, pharmaceuticals, and medical fields. It adopts advanced DC ionization technology, enabling efficient and stable ion delivery through long pipelines to achieve comprehensive electrostatic control in tight spaces or longitudinal extension areas. Compatible with clean dry air or nitrogen, the device ensures seamless integration into ultra-clean environments. It also supports MODBUS RTU communication, facilitating connection to the factory’s MES system for intelligent monitoring and management.

Product Features:

• Long-distance ion delivery for coverage of hard-to-reach areas

• DC ionization technology for efficient and stable transmission

• Compatible with clean dry air & nitrogen, zero contamination risk

• Compact structure for easy integration into existing equipment

• Intelligent status indication for clear visibility of operational conditions

• Single Crystal Silicon ion needle, greatly reducing wafer contamination risk

• hole-machine power consumption<1.5W for energy efficiency and environmental friendliness