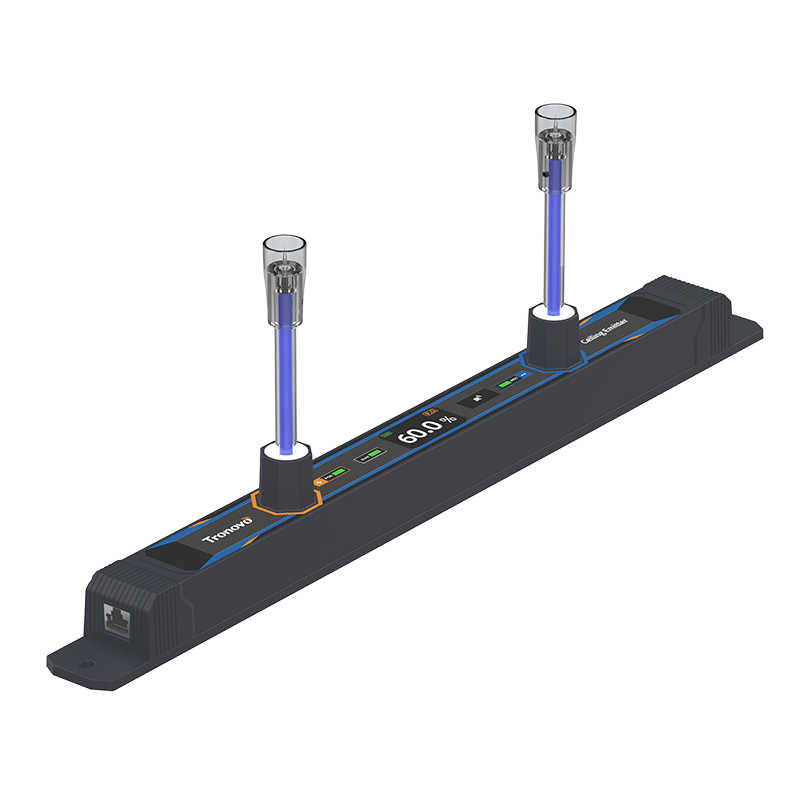

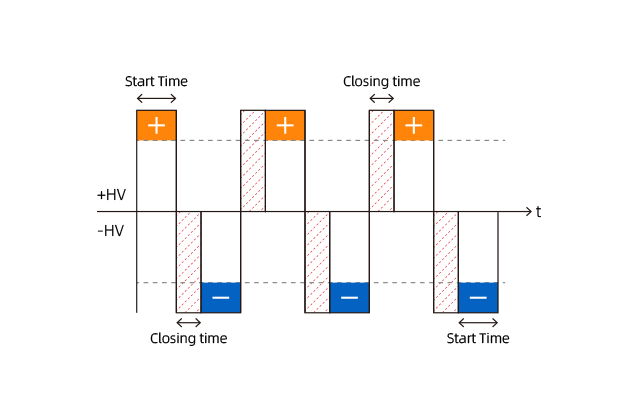

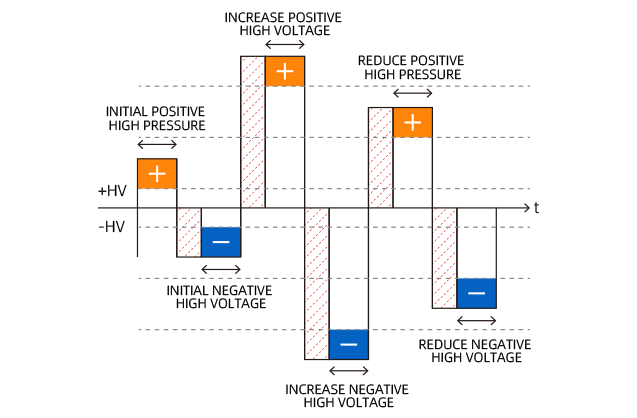

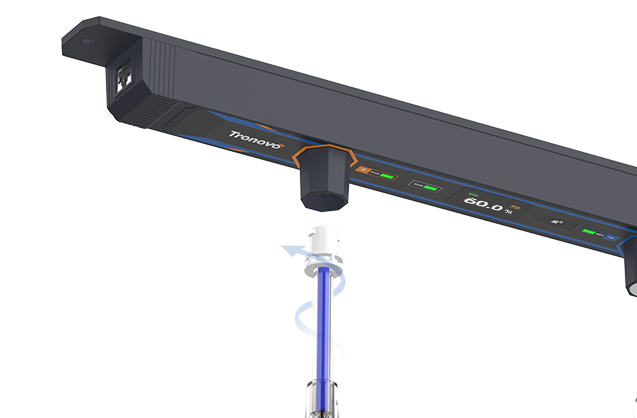

Tronovo room ionization system integrates user-friendly design with high-performance technology, providing an intuitive and stable electrostatic control solution. The device features an LCD-LED display and three-color indicator lights, offering clear and highly visible operational status. Its built-in fully digital control circuit ensures excellent ion balance and static elimination performance over the long term. The unique shutdown time function effectively expands the range of static elimination.

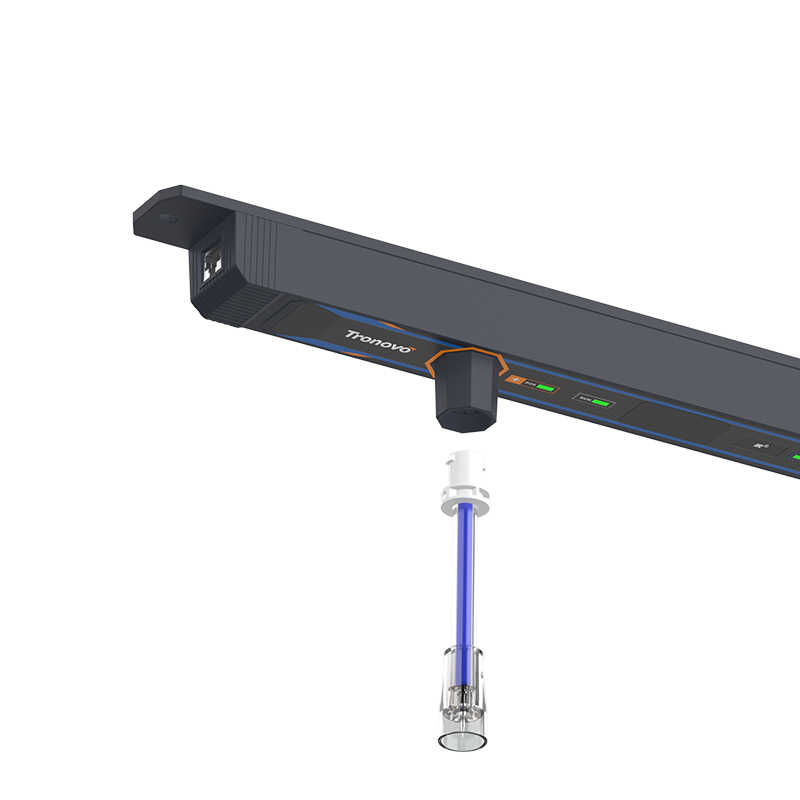

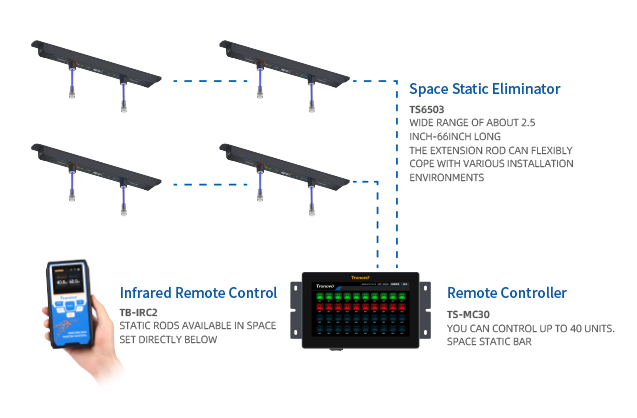

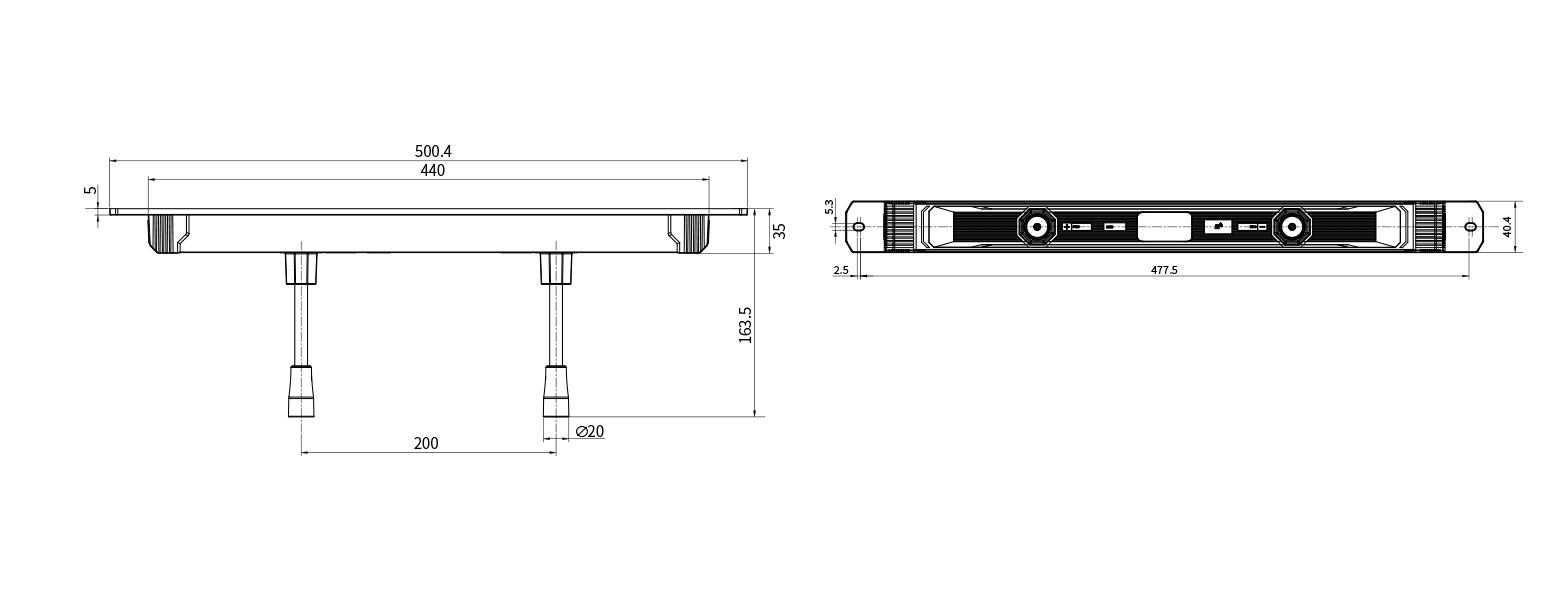

The system supports setting ion output voltage, generation time, and alarm thresholds over a wide range, adapting to diverse application scenarios. It utilizes single-crystal silicon electrodes with ultra-low particle emissions, and the ionization rod module offers various length options from 2.5 inches to 66 inches. Users can conveniently operate the system via an IR remote control, handheld terminal, or monitoring terminal, and it supports networking multiple devices for centralized monitoring and intelligent management.

Product Features:

• Equipped with an LCD screen and three-color indicator lights, the operating status is clear at a glance.

• Fully digital circuit control ensures long-lasting and reliable ion balance and static elimination effects.

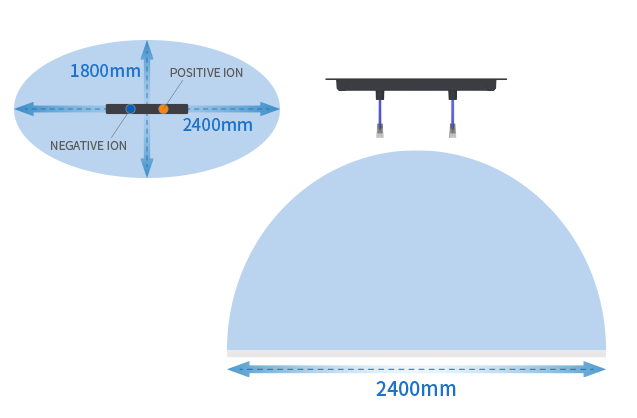

• Unique turn-off time function enables longer distance and wider range static neutralization.

• Key parameters such as output voltage, time, and alarm threshold are all flexibly adjustable.

• Uses ultra-low particle single-crystal silicon electrodes, and the ionization rod is available in multiple lengths.

• Supports setting and management via remote control, handheld terminal, and monitoring terminal.

• Multiple devices can be networked for centralized monitoring and unified management.