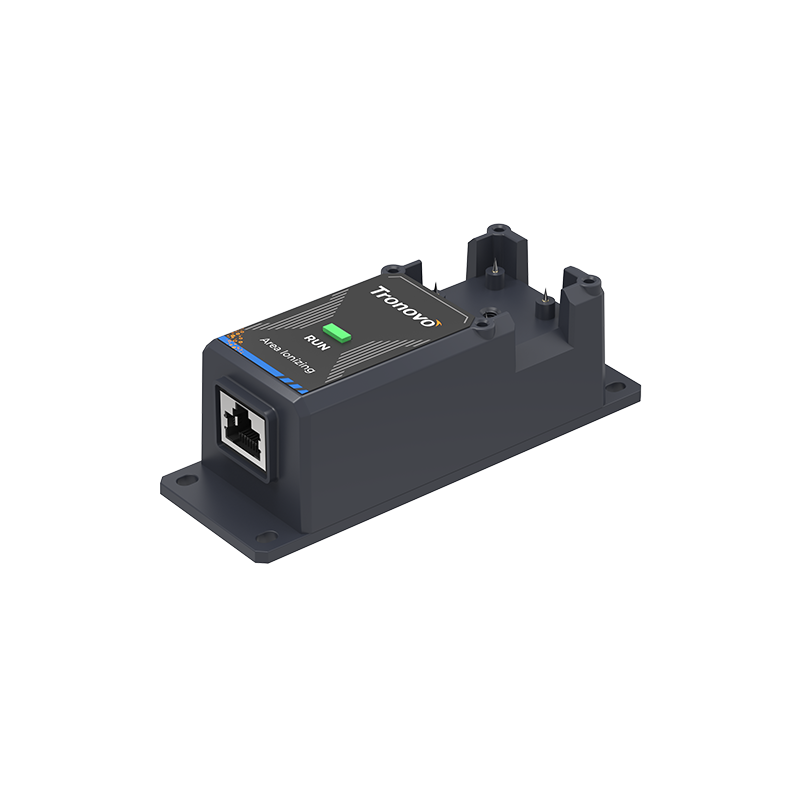

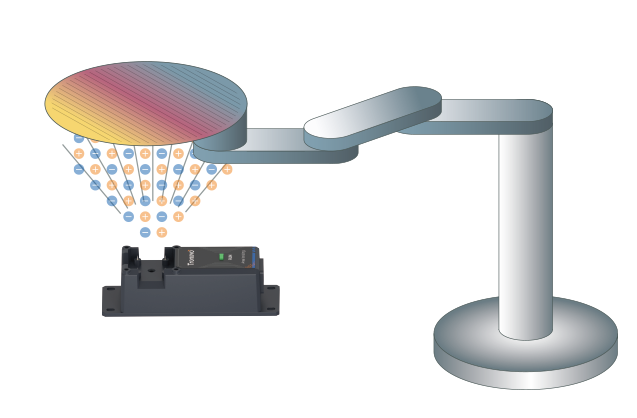

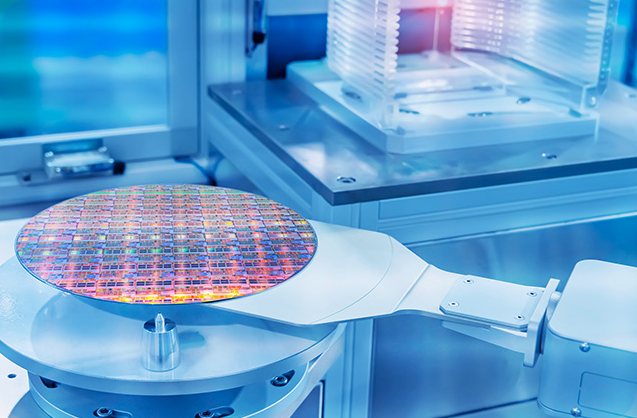

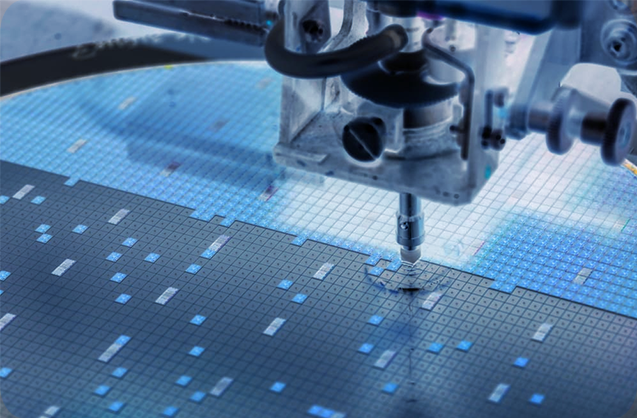

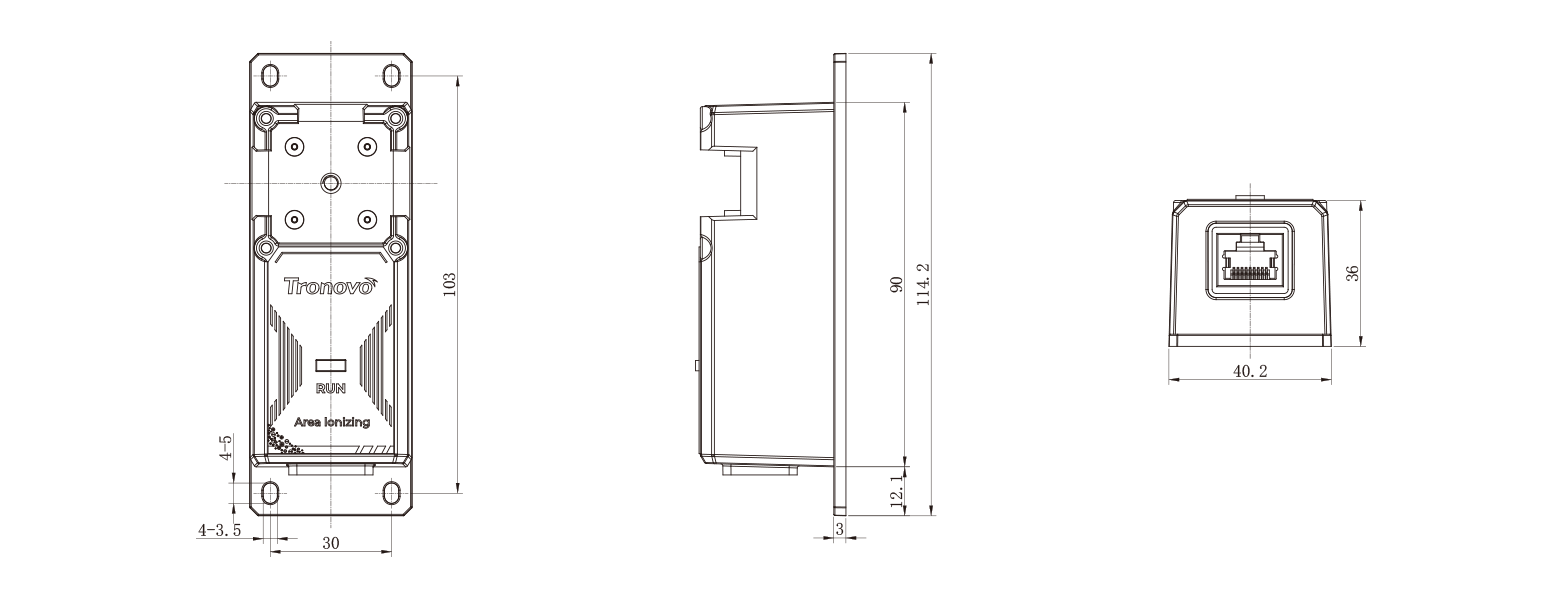

Tronovo DS827R Steady-State DC In-tool Ionizer is designed for laminar flow clean environments in high-end manufacturing industries such as semiconductors and panels. It employs innovative Single-crystal Silicon ion needles and steady-state DC ionization technology, which not only efficiently and continuously eliminates static, but also fundamentally eliminates particulate pollution generated by the ion needles.The unique quadrupole ion needle design enables effective ionization at close range (approximately 7.6 cm). The ion generator features a compact structure and support 24VDC power supply. It can be easily integrated into the tight space inside equipment, directly addressing electrostatic particle adsorption and discharge damage, and ensuring process cleanliness and product yield.

Features:

• Compact size, easy integration into various devices

• Quadrupole ion needle design

• Single-crystal Silicon ion needles, Reduce particulate pollutants at source

• 24VDC power supply, real-time Fault Diagnosis and Alarm

• Steady-state DC technology provides continuous and balanced positive and negative ion output

• Designed for a laminar flow environment in cleanrooms, it does not affect airflow organization or cleanliness

• Steady-state DC technology, Safeguarding high-end manufacturing