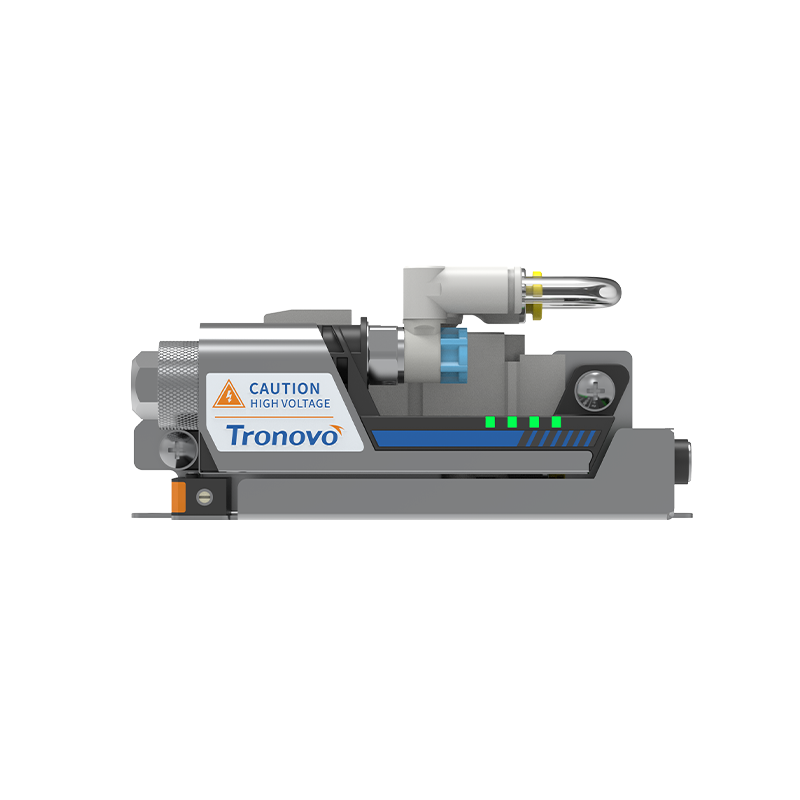

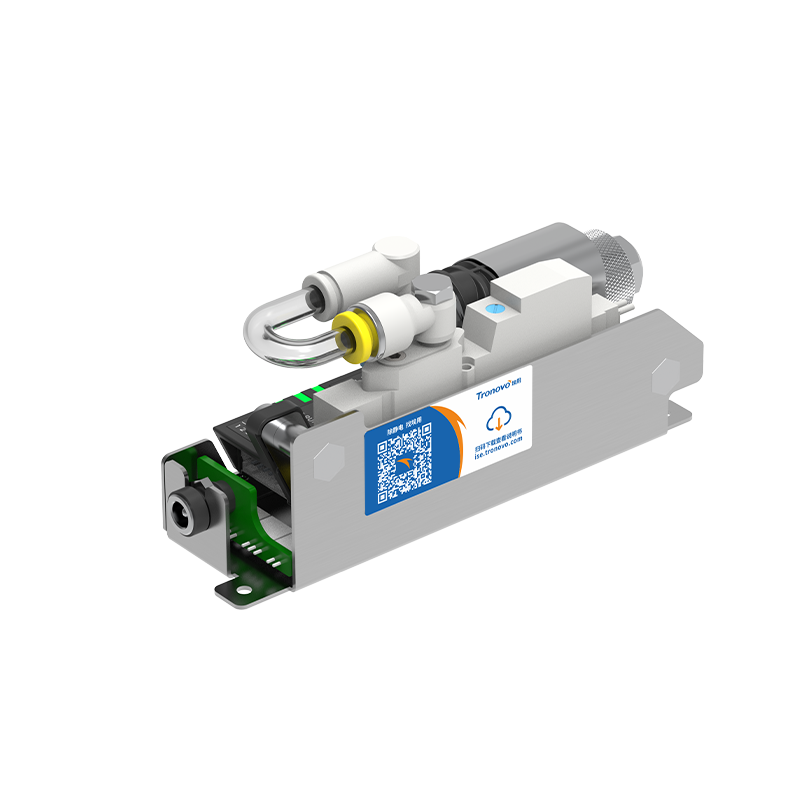

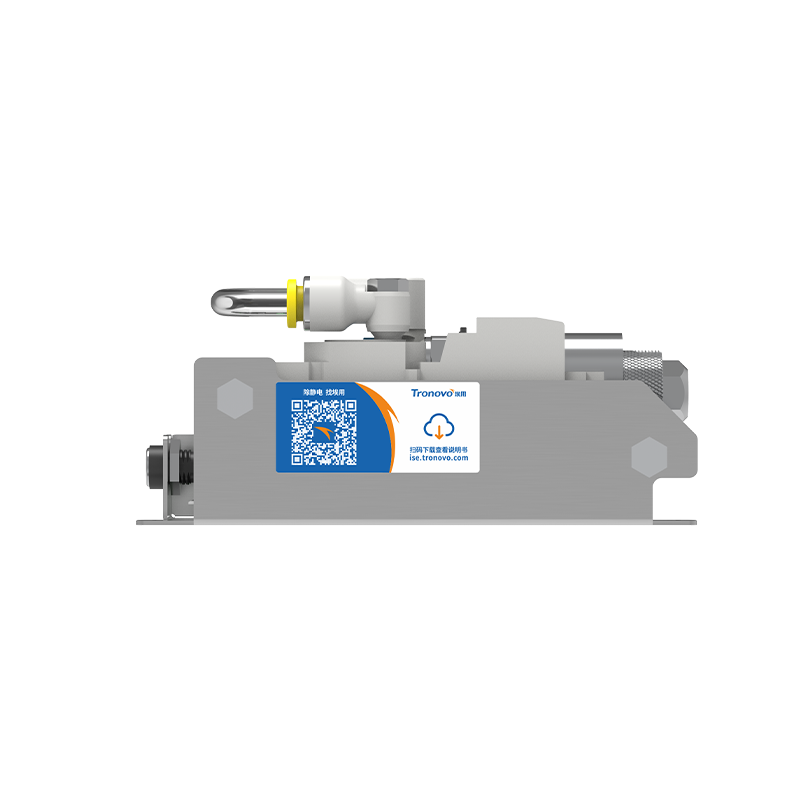

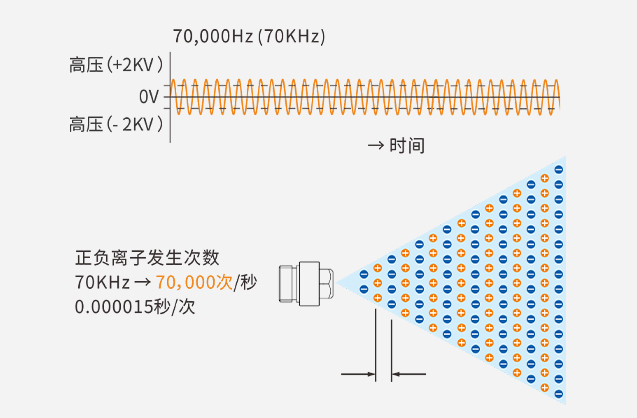

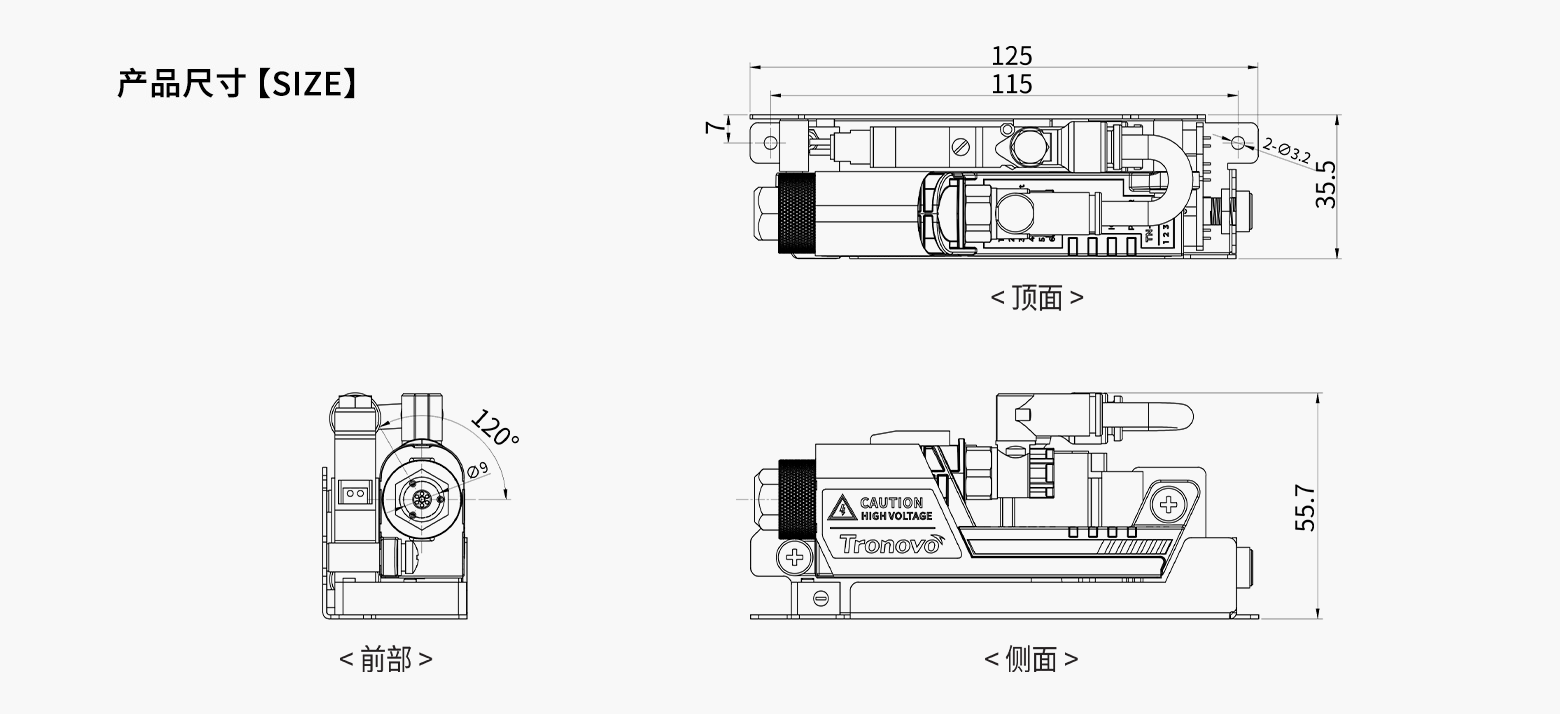

In precision industries such as plastic products and electronic components production, particle pollution caused by electrostatic force is a common problem, and dust particles adsorbed on charged surfaces are difficult to remove. This miniaturized induction-type ionic air nozzle adopts high-frequency AC ionization technology and is specially designed for automation process and space-limited scenes. It is an efficient anti-static dust removal equipment. The built-in photoelectric sensor automatically starts when the object approaches the sensing surface, releases a powerful ionized air flow to quickly neutralize electrostatic charges, efficiently removes adsorbed particles, is suitable for electronic assembly and surface cleaning of plastic parts, and helps to improve production yield and product cleanliness.

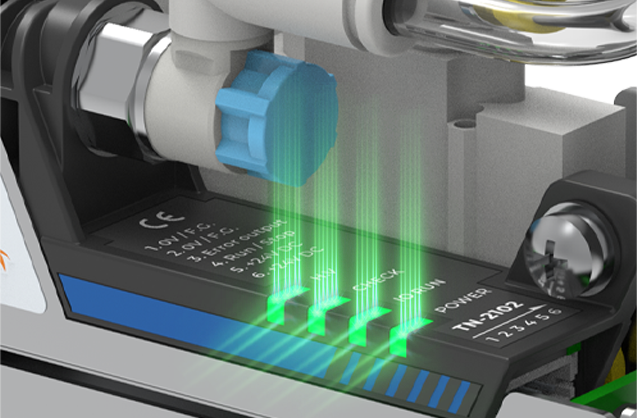

Features:

•Standard induction type compressed air on/off sensor, imported anti-static components, long service life

•Sensors and solenoid valves adopt imported electrostatic removal devices, reliable action and stable performance

•New upgrade discharge needle detection function, ion needle abnormal maintenance warning, reduce the risk of downtime

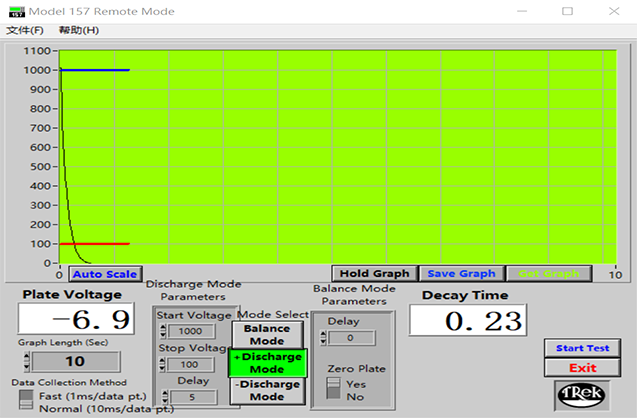

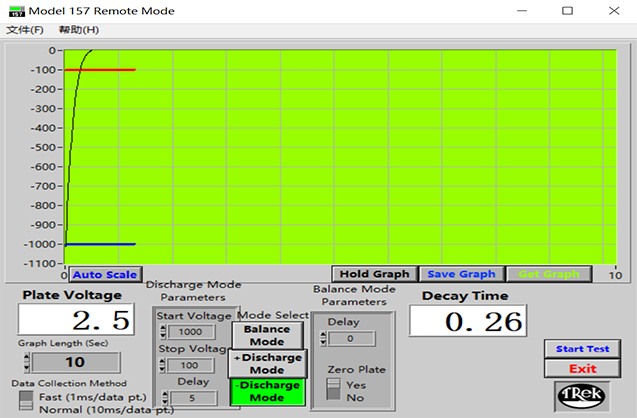

•Has excellent ion balance performance, can be a long time efficient in addition to static electricity, to meet the electronic