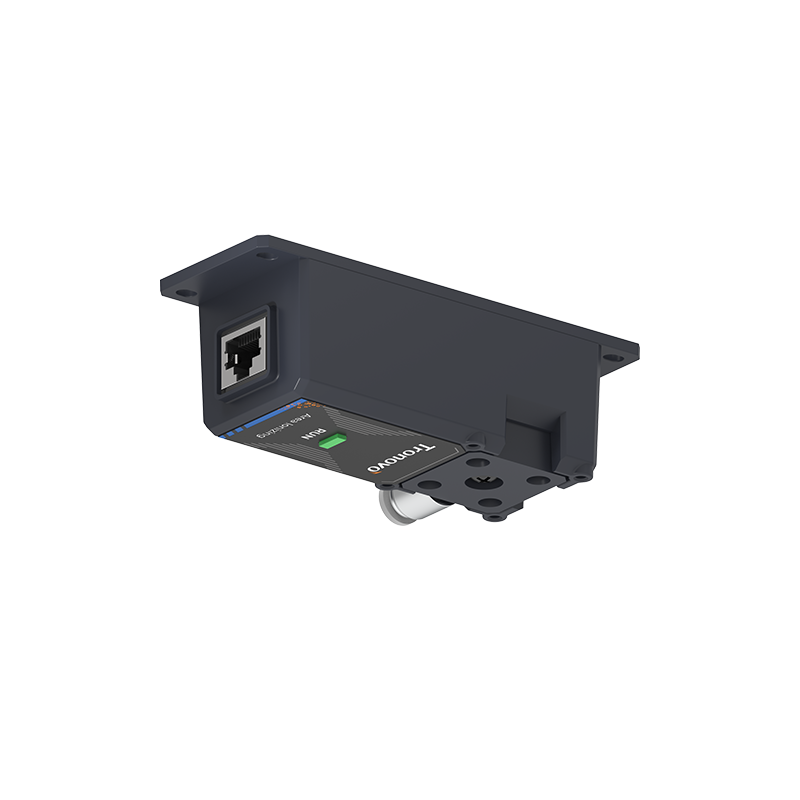

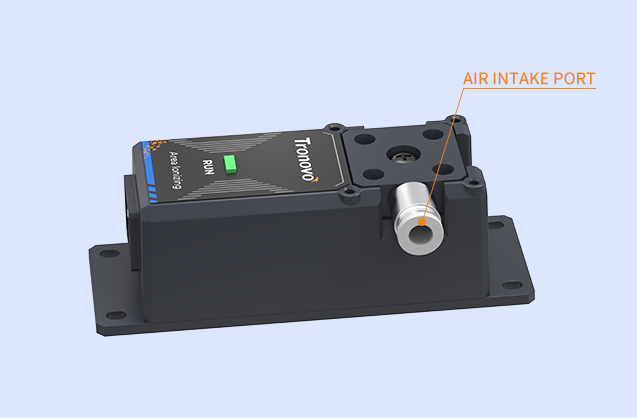

A gas-assisted In-tool Ionizer designed for high-end precision manufacturing environments.Its innovative gas-assisted technology integrates a micro power supply and control circuit into an ultra-compact body, facilitating seamless integration into the confined internal spaces of process equipment in semiconductor, wafer processing, flat panel display (FPD) and medical device sectors.When supplied with a minimal volume of clean, dry air or nitrogen, this unit provides consistent, high-performance static neutralization unaffected by ambient air current. It effectively mitigates particle contamination induced by electrostatic adhesion, ensures process cleanliness and product yield at the source, and is an optimal solution for dependable static control in modern smart manufacturing lines.

Product Features:

• Air-assisted Stable Performance: Powered by an independent clean air supply, it ensures stable and reliable electrostatic elimination performance.

• Ultra-Compact Design:Highly integrated miniature structure for easy installation in extremely confined spaces inside equipment.

• Status Visualization: Equipped with three-color LED and remote alarm signal for real-time working status monitoring.

• Safe & Easy Integration: 24V DC safe power supply, compliant with industrial standards, for simple and fast deployment.

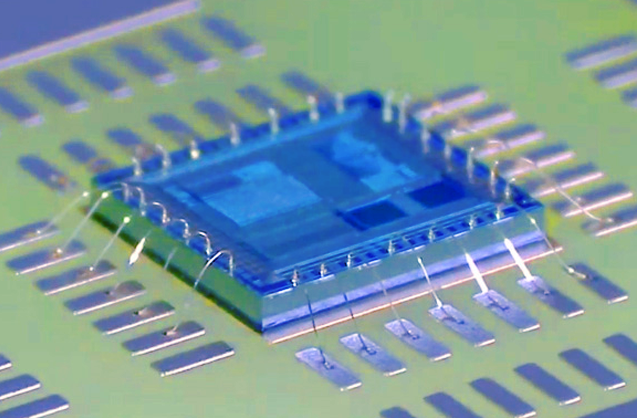

• Clean & Anti-Contamination: Single Crystal Silicon ion needle combines with gas-assisted purging reduce particle contamination risks at the source.

• Extended Maintenance Cycle: The gas-assisted design reduces ion needle contamination ,significantly prolonging maintenance intervals.