An intelligent In-tool Ionizer adopt steady-state DC technology, specifically design to address static charge and particulate contamination in confined spaces such as equipment interiors, conveyor belts, and workstations within high-end industries such as semiconductors, flat panel displays, precision electronics, and pharmaceutical manufacturing.

Featuring ion self-balancing functionality, enables real-time adaptation to environmental changes to ensure stable and efficient electrostatic neutralization performance.

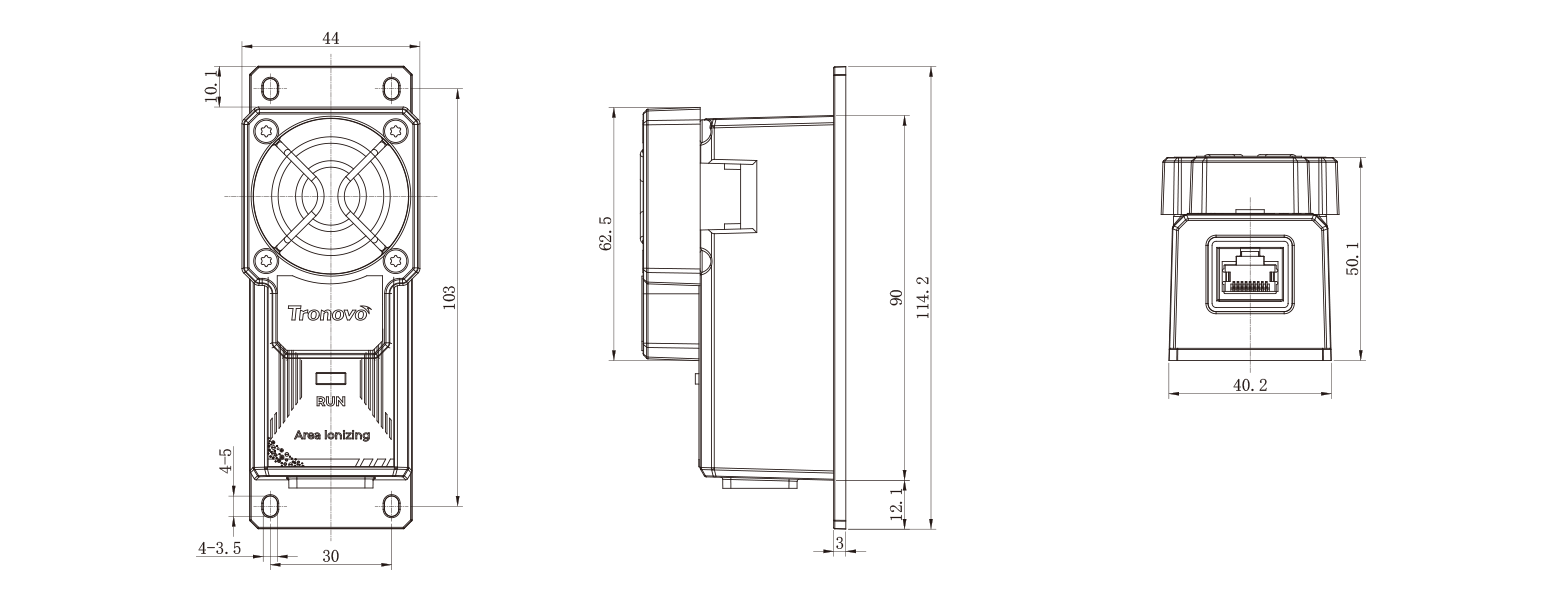

Its compact design, ultra-low particle emission compatibility, and support industrial communication remote monitoring capabilities enable seamless integration into automated production lines and precision equipment, effectively enhancing product yield while ensuring production safety and process reliability.

Features:

• Real-time monitoring and automatic adjustment to maintain optimal ion balance

• Three-color LED indicator for clear display of operation, cleaning, and faults

• Ultra-thin and compact design, easily integrated into various equipment interiors

• 24VDC safe voltage, easily connect to device circuit

• Standard RS485 interface for remote monitoring and intelligent adjustment