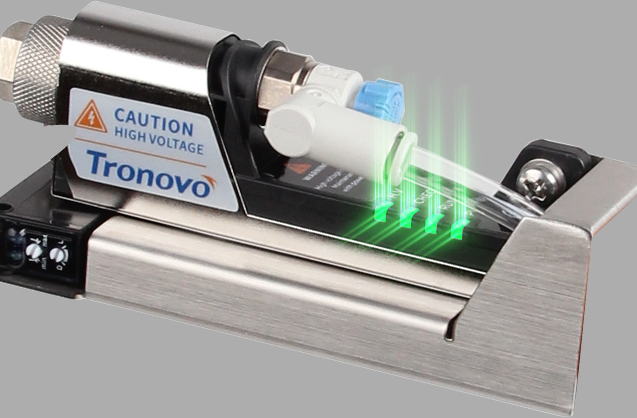

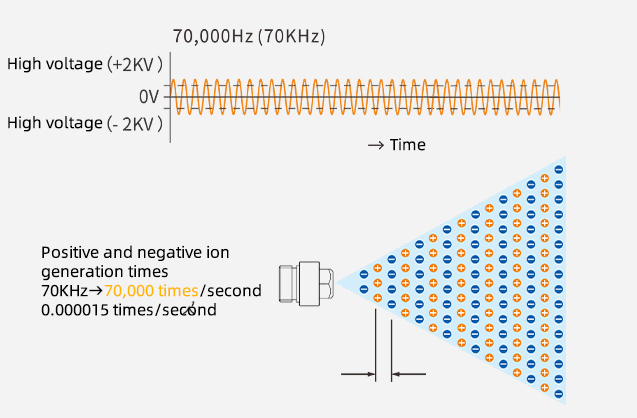

High-frequency ion wind snake is the necessary equipment for electrostatic control in the electronics industry and strictly complies with ESD protection standards. It integrates photoelectric sensors to achieve "induction and blowing" ion wind, free hands, and operate intelligently and conveniently. As an efficient static eliminator, its precise airflow control effectively guarantees precision electronics manufacturing. The products are made of high quality materials and have undergone strict quality control and testing to ensure long life and low failure rate. It is a reliable choice to improve the electrostatic protection capability of the production line.

Features:

• High-efficiency electrostatic elimination and dust removal to ensure that there is no charge residue on the surface of the product and improve the yield of electronic production

• Easy to operate-photoelectric sensor, induction that is blowing ion wind, the liberation of both hands

• Flexible serpentine tube design, 360 degrees free adjustment, suitable for precision electronic assembly angle

• ESD protection safety, eliminate the risk of abnormal discharge/short circuit, ensure the safety of production line

• Low ozone ion wind snake, compressed air with ion balance control system

• Industrial-grade durable, anti-corrosion materials, anti-static equipment long life

• Optional foot switch, two-hand operation precise airflow control

• Optional air filter, intercept compressed air impurities, protect precision components