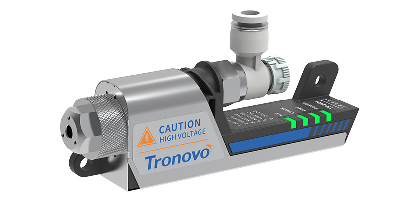

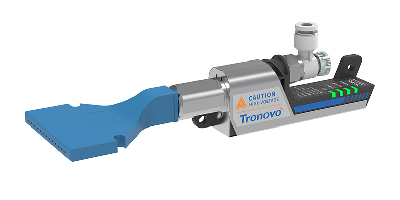

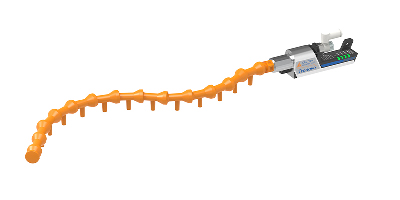

Ultra-compact static eliminators are designed for tight spaces, precisely targeting workpieces, efficiently neutralising static electricity and simultaneously completing precision dust removal. A wide range of nozzles are available to meet diverse static elimination and cleaning needs. The core adopts high-frequency AC technology to achieve extremely stable ion balance. Its ion balance performance is not affected by changes in air pressure and installation distance, to ensure that the installation is ready to use, completely eliminating the need for cumbersome adjustment operations, is the ideal electrostatic elimination equipment to enhance electrostatic protection and cleanliness in electronic manufacturing, precision assembly and other scenes.

Features:

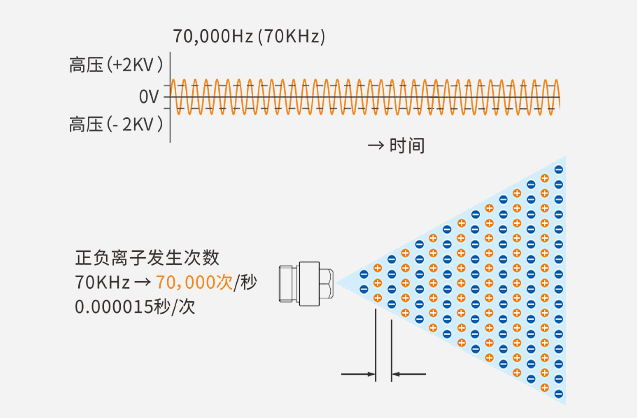

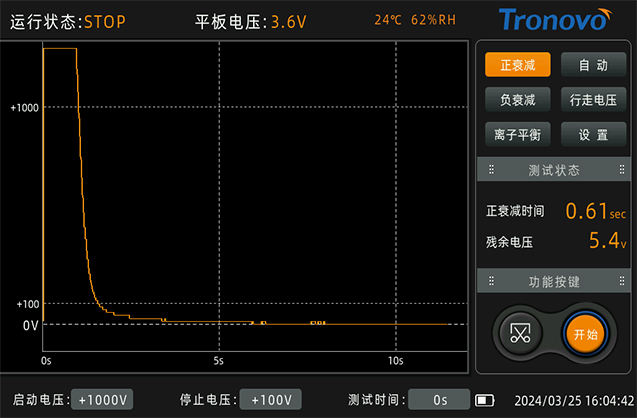

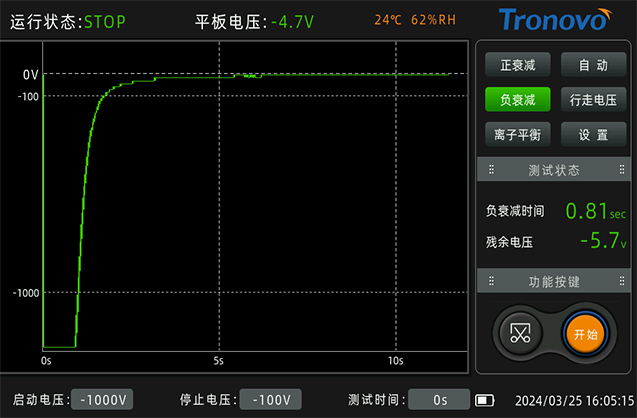

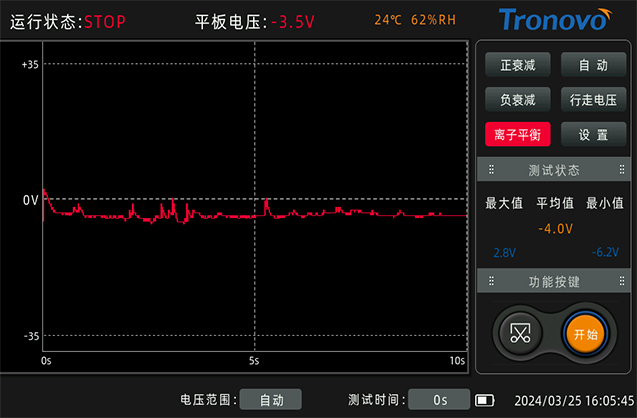

• High-frequency AC ionisation technology, achieving extremely stable ion balance, ensuring reliable static elimination

• Ultra-compact static eliminator design, easy to integrate into the equipment, space-saving

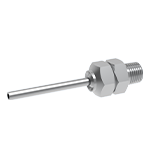

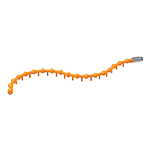

• A wide range of nozzles, according to the need to choose, to meet the different applications of static elimination and cleaning and dust removal

• IO control function (signal input/output), support for automation on-line, to enhance the automation of the production line

• Safe static eliminator design: 24V DC low voltage power supply, no need for high voltage cable, the operation of safe static elimination equipment. Power supply, no need for high-voltage cables, safe and secure operation

• Equipped with operating status indicator, real-time monitoring of equipment operating status

• Ion needle is easy to disassemble and clean, easy maintenance, reduce equipment maintenance costs

• 270mm long-distance static elimination, expanding the area of static elimination, especially suitable for space-constrained places