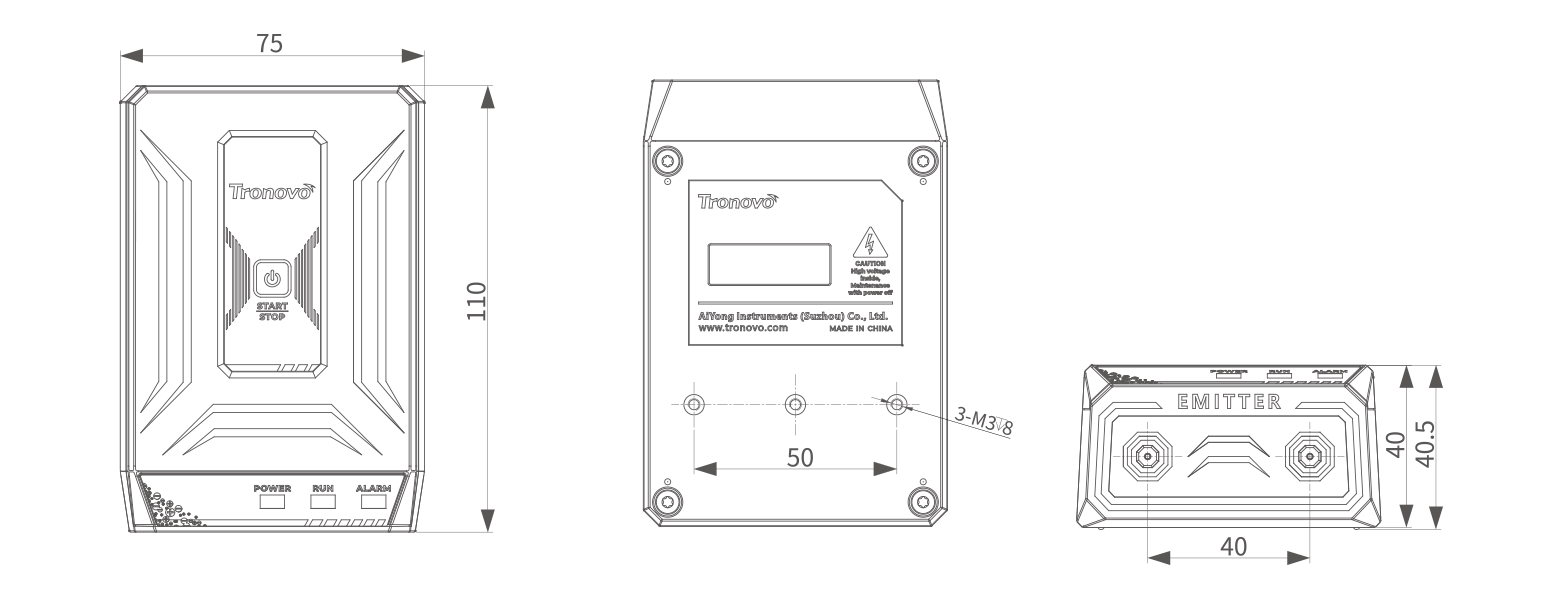

Miniature windless static eliminator, palm size fits narrow space and equipment integration. Relying on DC technology to generate ions, no airflow interference, eliminate dust pollution, zero noise operation. Intelligent LED real-time monitoring of working conditions, support PLC and RS485 interconnection, easy maintenance. Quickly eliminate static electricity within 10-40cm, adapt to chip packaging, precision assembly, micro-weighing and other scenes, guard high-value components and data accuracy, is the ideal choice for precision operations.

Product features:

• Ultra-small body only palm large, easy to integrate equipment inside or narrow space

• No airflow design, from the root to avoid the risk of secondary pollution.

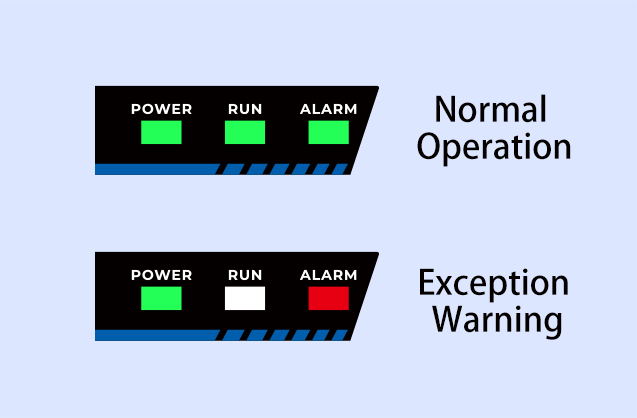

• Intelligent LED indicator, real-time feedback running, standby or abnormal state

• Support PLC control and RS485 protocol, seamless access to industrial networks

• Run the whole zero noise, adapt to the high demand for mute precision work environment.

• Low daily maintenance requirements, significant savings in long-term use and maintenance costs.

• 10-40cm effective range, quickly eliminate static electricity, ensure efficient and accurate operation.