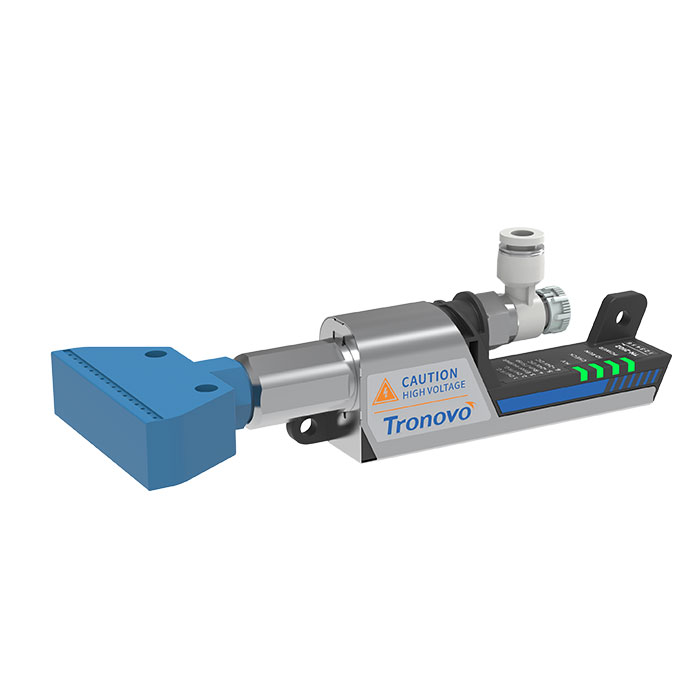

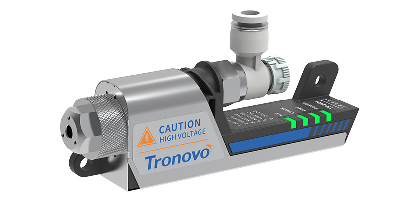

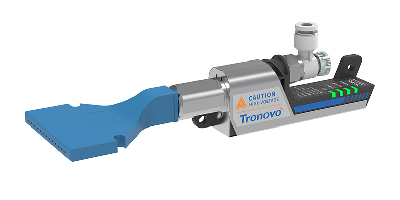

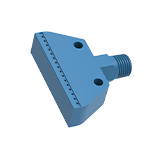

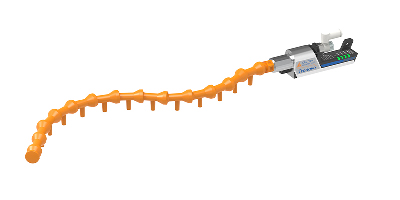

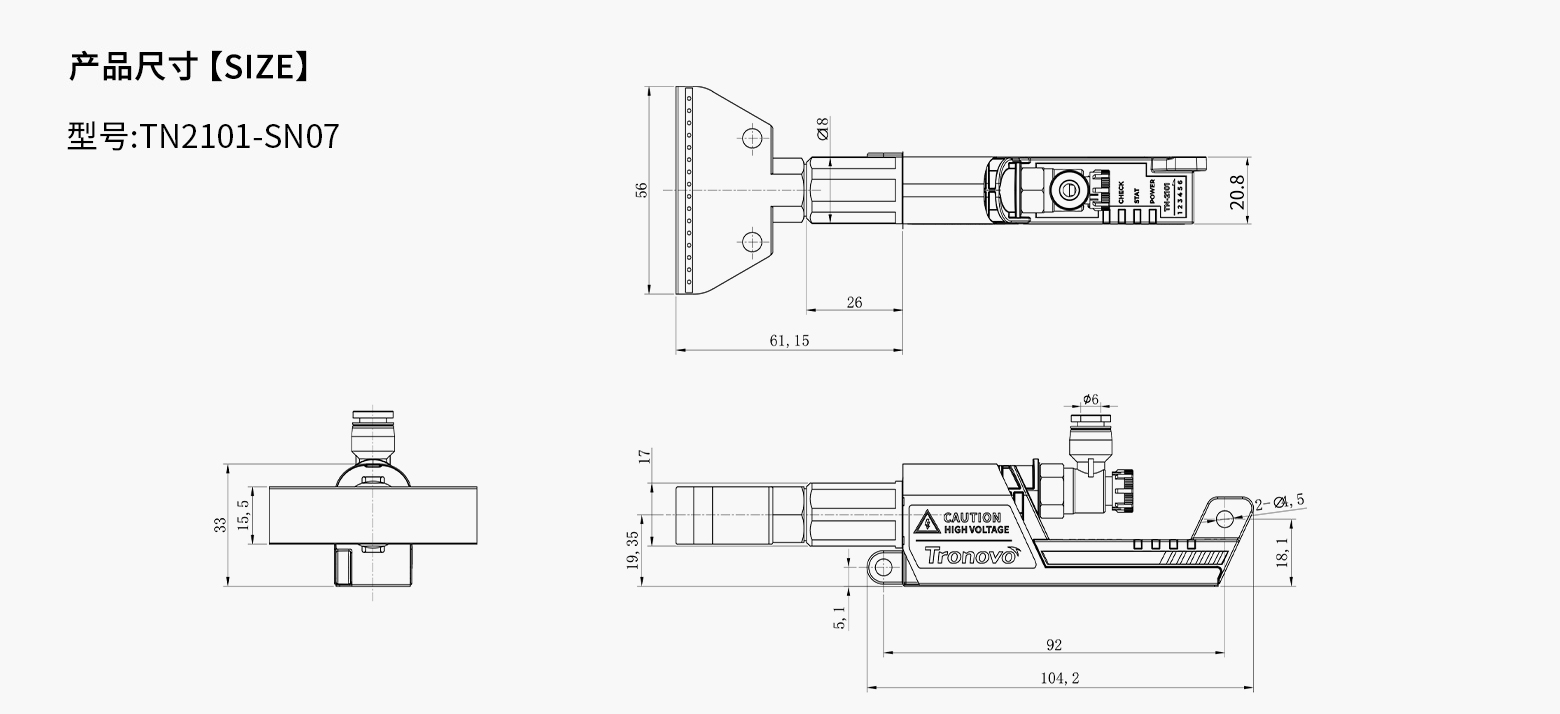

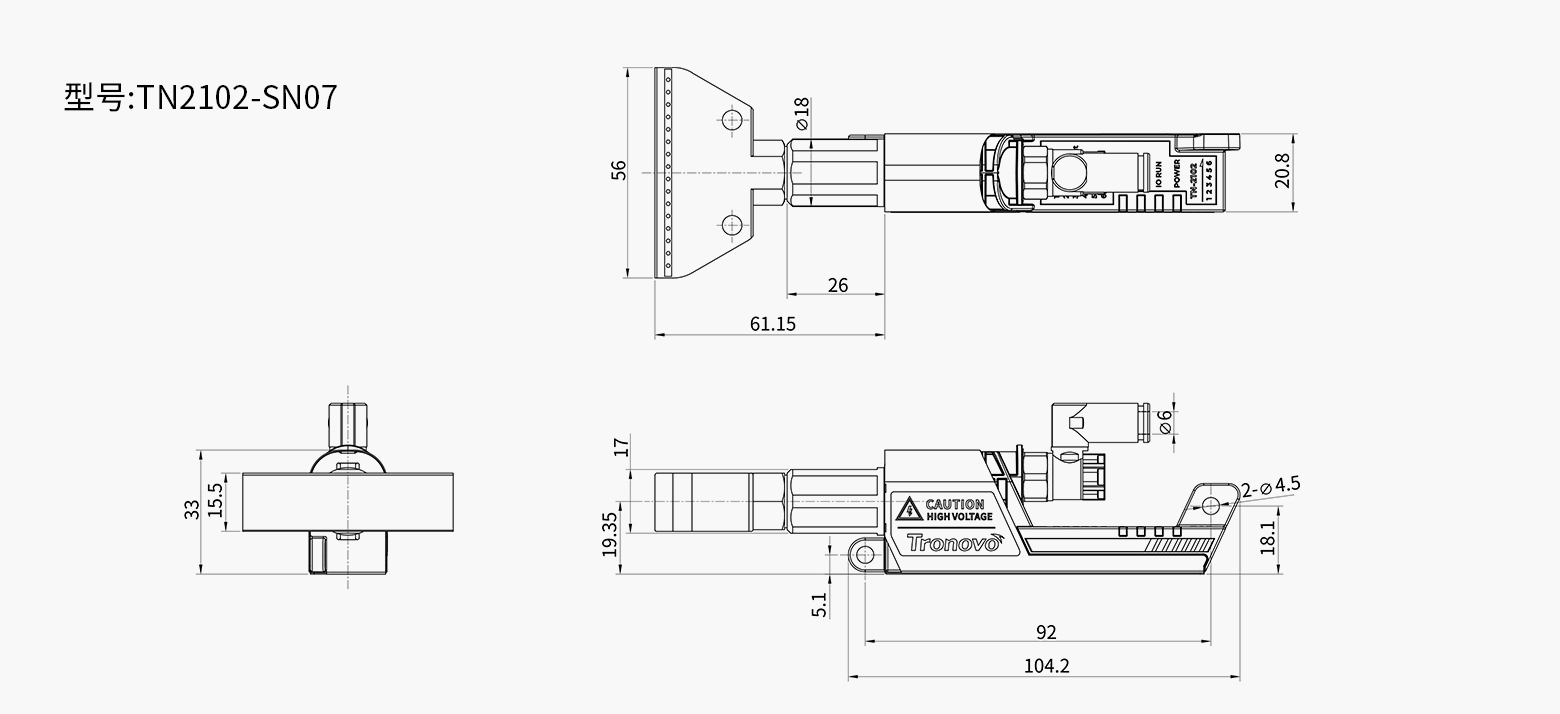

Ultra-compact ionic nozzle is designed for narrow space, easy to target the workpiece to accurately remove dust and other pollutants, simultaneous and efficient elimination of static electricity, to meet the needs of electronic components, precision instruments and other scenarios of cleaning. Equipped with a wide range of nozzle types, which can be flexibly selected according to different workpiece shapes and cleaning ranges to enhance the adaptability of operation. Adopting high-frequency AC technology, the ion balance is stable and precise, and is not affected by the supply air pressure and installation distance, so there is no need for cumbersome debugging after installation, which reduces the maintenance cost. Applicable to PCB boards, lens modules, semiconductors and other precision manufacturing processes, efficiently solving the problem of electrostatic adsorption pollution and optimising production cleanliness.

Features:

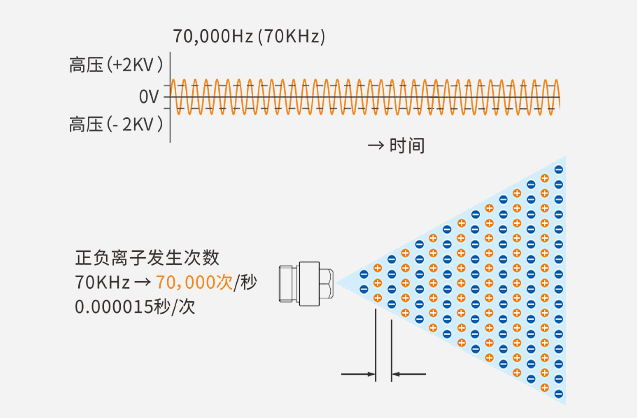

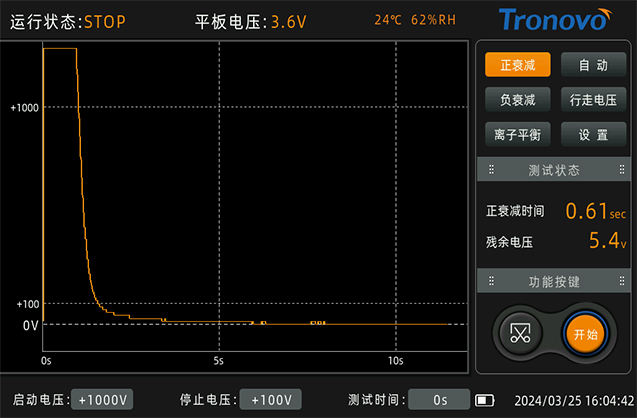

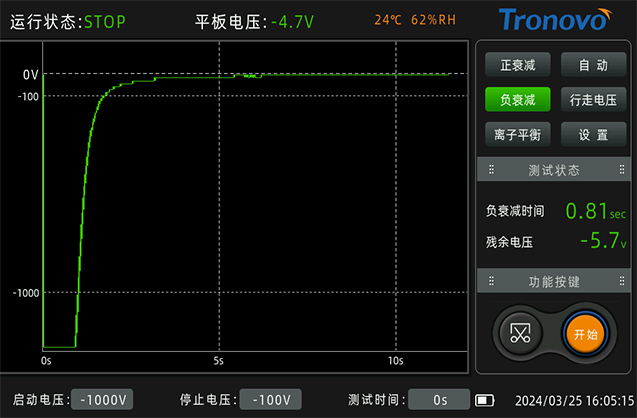

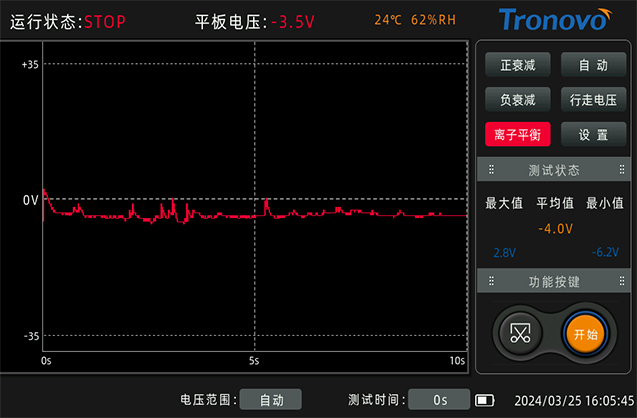

• High-frequency AC ionisation technology, equipped with a stable ion balance system, suitable for precision electronic de-static scenes

• Super small ion nozzle design, easily embedded in the equipment, saving installation space

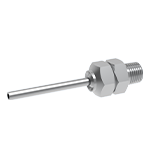

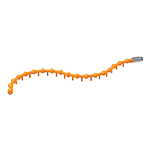

• Multi-specification nozzles can be selected, according to the cleaning needs of the flexible matching, to enhance the adaptability of the operation

• Support signal input and output control, through the IO communication to achieve automated on-line, compatible with the integration of the production line

• 24V DC safe power supply design, without high-voltage cable, to ensure the safety of the operation. No need for high voltage cables to ensure safe operation and comply with industrial safety standards

• Equipped with operation status indicator, real-time monitoring of operation status, easy to maintain

• Easy to dismantle and clean ionic needles, easy to maintain and reduce equipment maintenance costs

• Air jet angle is perpendicular to the threaded surface, specially designed for small spaces, suitable for restricted places.