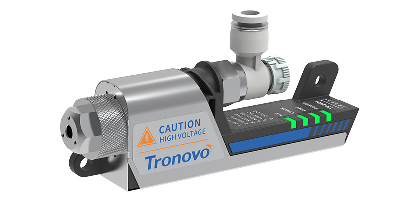

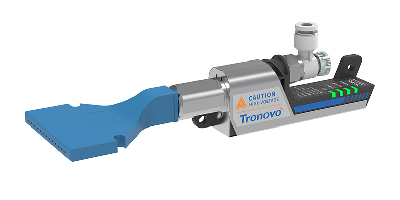

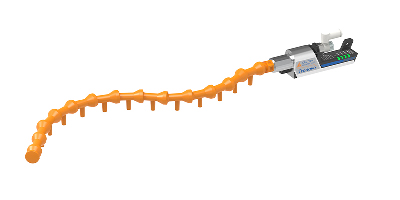

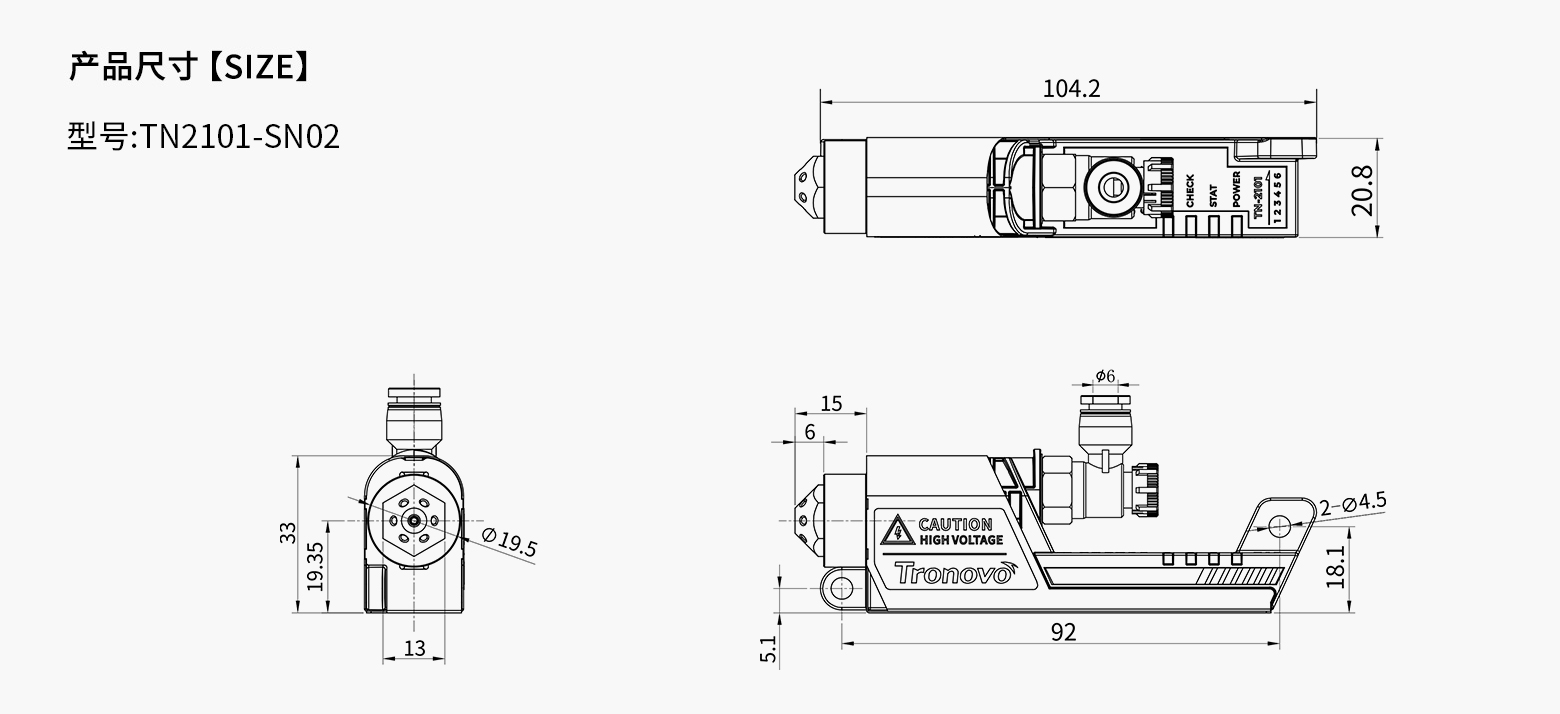

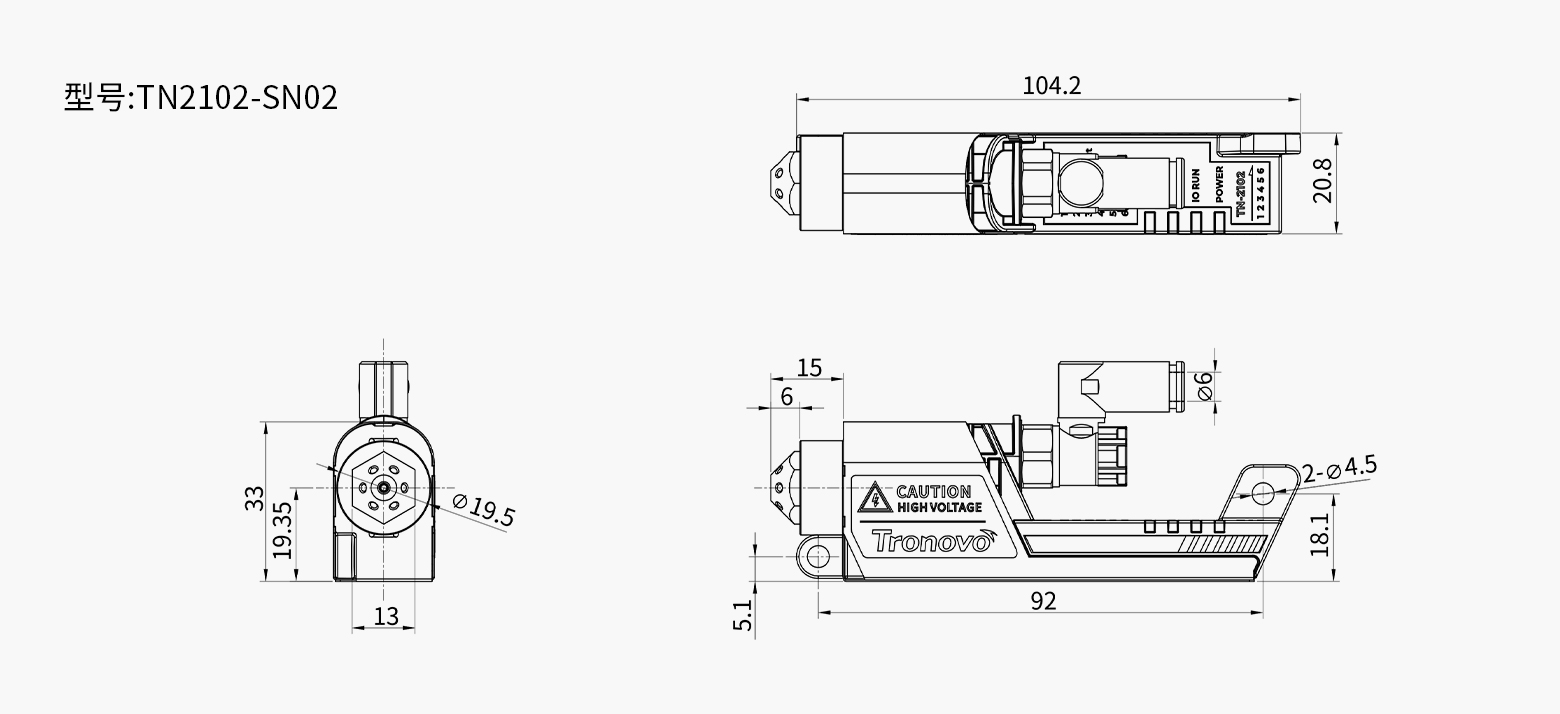

The ultra-compact static eliminator designed for small spaces precisely targets workpieces, removes dust and contaminants, and simultaneously eliminates static electricity efficiently. Provides a variety of nozzle types, can be flexibly selected according to the application scenario. The core adopts high-frequency AC technology to achieve extremely stable ion balance, with performance far exceeding that of ordinary DC products. The significant advantage is that its ion balance is not affected by changes in supply air pressure and installation distance, so there is no need for cumbersome adjustments after installation, which significantly improves production efficiency and yield rate. It is the ideal solution for static elimination and cleaning maintenance in precision electronics, semiconductor, injection moulding and other industries.

Features:

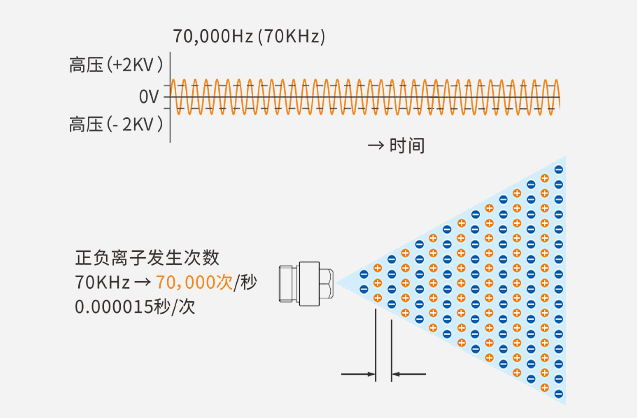

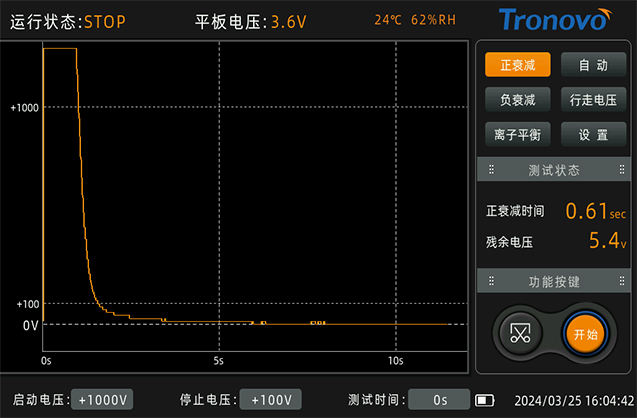

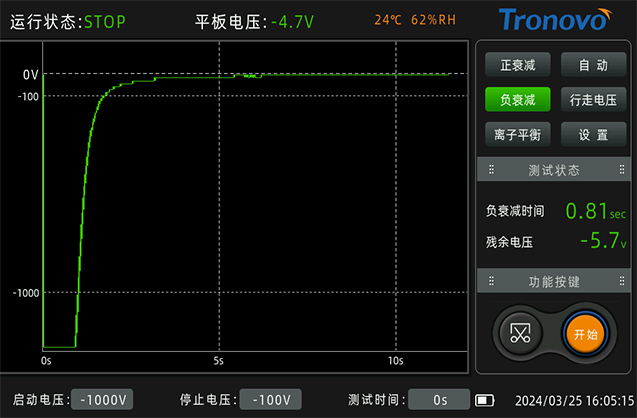

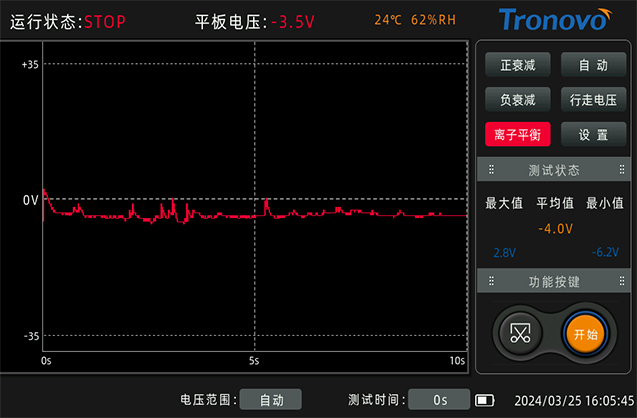

• High-frequency AC ionisation technology, ion balance is very stable, static elimination effect is more reliable

• Ultra-small ion nozzle design, can be easily assembled into the equipment, saving installation space

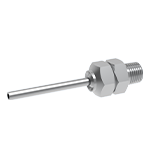

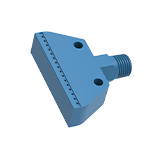

• A wide range of nozzle types, according to the precision cleaning, large area dust removal and other applications to choose from, adapted to a variety of scenarios

• Signal input and output control function, support for IO communication, to improve production efficiency

• 24V DC safety power supply design, no high-voltage cable The use of more assured

• with operating status indicator, real-time display of the operating status of the equipment, to facilitate timely troubleshooting

• maintenance is convenient, the ion needle can be easily removed and cleaned, to extend the service life of the equipment

• 45-degree spray angle to make the airflow more diffuse, static elimination of a wider range of more uniform cleaning