| MODEL NUMBER | Body style

| Nozzle Accessories | Material | ILLUSTRATE |

| Diffusion nozzles |

MODEL:DN251-SN01 |  MODEL:TN-SN01 | SUS 304 | Straight lines diffuse the air |

| Shower-type nozzles |

MODEL:DN251-SN02 |  MODEL:TN-SN02 | SUS 304 | 45 degree spray angle for wider air diffusion |

| Connected hose nozzles |

MODEL:DN251-SN03 |  MODEL:TN-SN03 | Metal | Ion nozzle body and conduit connection nozzle can be connected to any bend of the conductive conduit conduit diameter ø 6mm, the minimum bending radius: R25mm, need to purchase additional TN-SN10 adapter to use. |

| Adjustable point nozzle |

MODEL:DN251-SN04 |  MODEL:TN-SN04 | SUS 304 | Can be in the range of 60 degrees, arbitrary adjustment of the spray angle to use first adjust the nozzle after the fixed nut, need to purchase additional TN-SN10 adapter to use! |

| Round-nosed nozzles |

MODEL:DN251-SN05 |  MODEL:TN-SN05 | Plastics | Powerful straight-line air can be injected from a small hole at the front end, with the addition of the TN-SN10 adapter. |

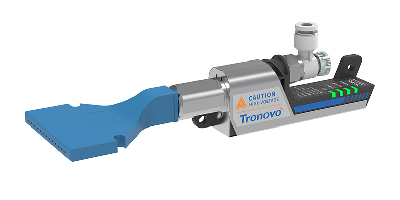

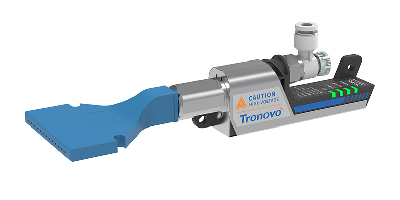

| Flat-head nozzles |

MODEL:DN251-SN06 |  MODEL:TN-SN06 | Plastics | Wide range of uniform electrostatic dust removal, requires additional TN-SN10 adapter for use |

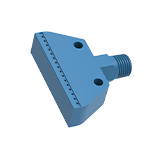

| 90-degree nozzle |

MODEL:DN251-SN07 |  MODEL:TN-SN07 | Plastics | The angle of the air jet is perpendicular to the threaded surface, making it ideal for space-constrained locations,Requires additional TN-SN10 adapter to use |

| Stick type side blow nozzle |

MODEL:DN251-SN08 |  MODEL:TN-SN08 | SUS 304 | De-static effective length 270mm can improve the de-static area suitable for space-restricted places, need to add the purchase of TN-SN10 adapter use |

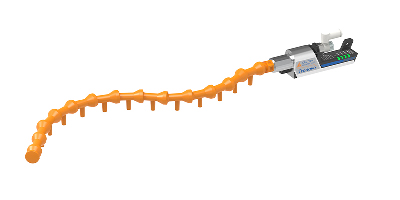

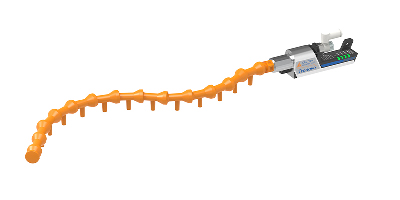

| Rod type side blow nozzle + bendable hose |

MODEL:DN251-SN09 |  MODEL:TN-SN09 | SUS 304 | De-static effective length of 270mm, the rod-type side blowing nozzle edge to the conductive conduit conduit diameter ø 6mm, the minimum bending radius: R25mm, the length of the conduit has a greater impact on the time to remove static electricity, please follow the site to do the choice of the appropriate, need to add the purchase of the TN-SN10 adapter to use! |

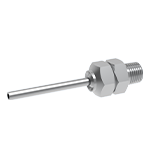

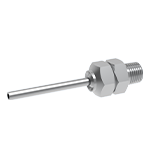

| Nozzle adapters |

|  MODEL:TN-SN10 | SUS 304 | RP1/4 (female) to M16×1.5 (male) is suitable between the nozzle and the thread of the static eliminator. |

| Bamboo gimbal nozzle |

MODEL:DN251-SN19 |  MODEL:TN-SN19 | Shuo material | It can be installed on DN251 or DN252, the default length of the product is 40cm, and there are 13 nozzles in total.

Customers can shorten or extend as needed. |

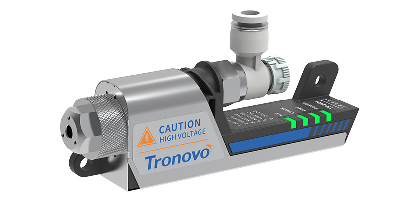

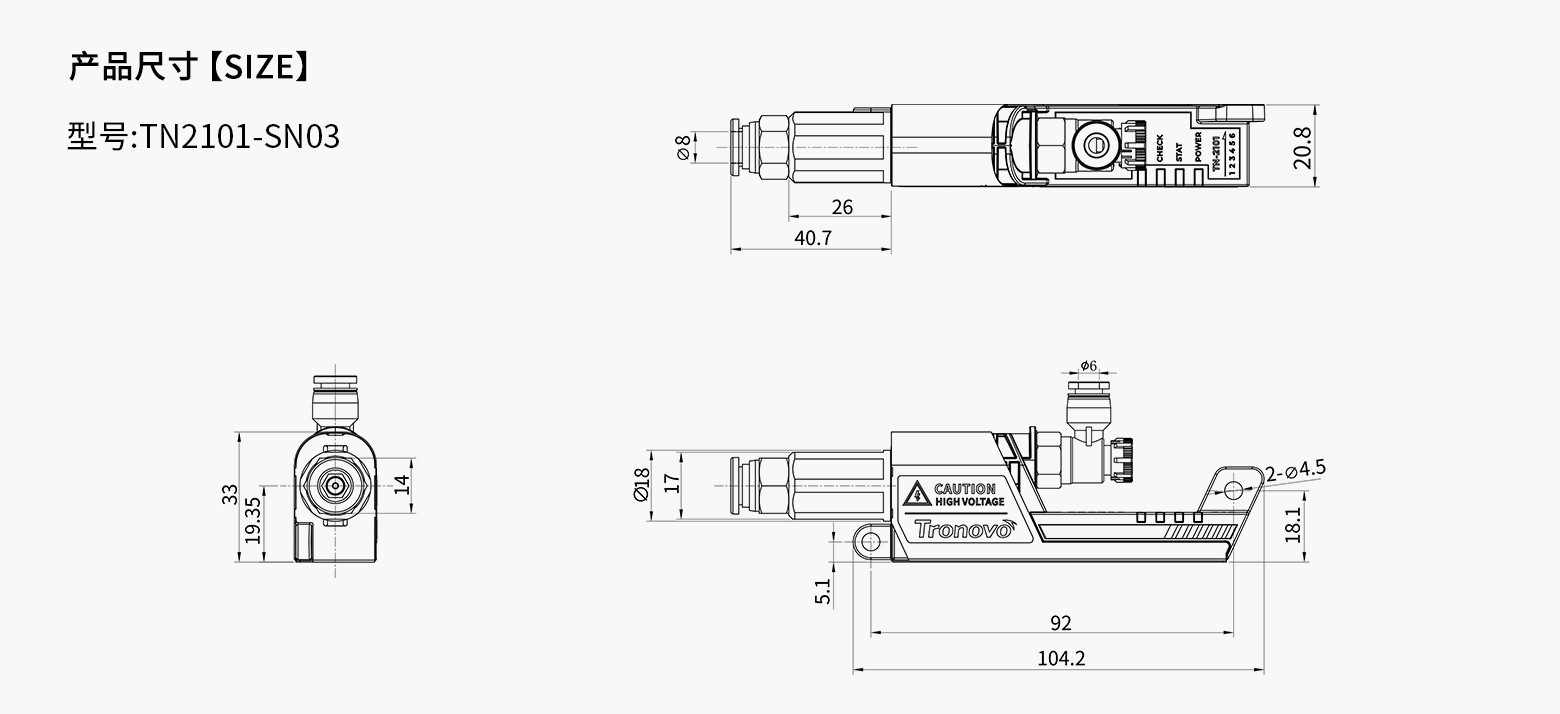

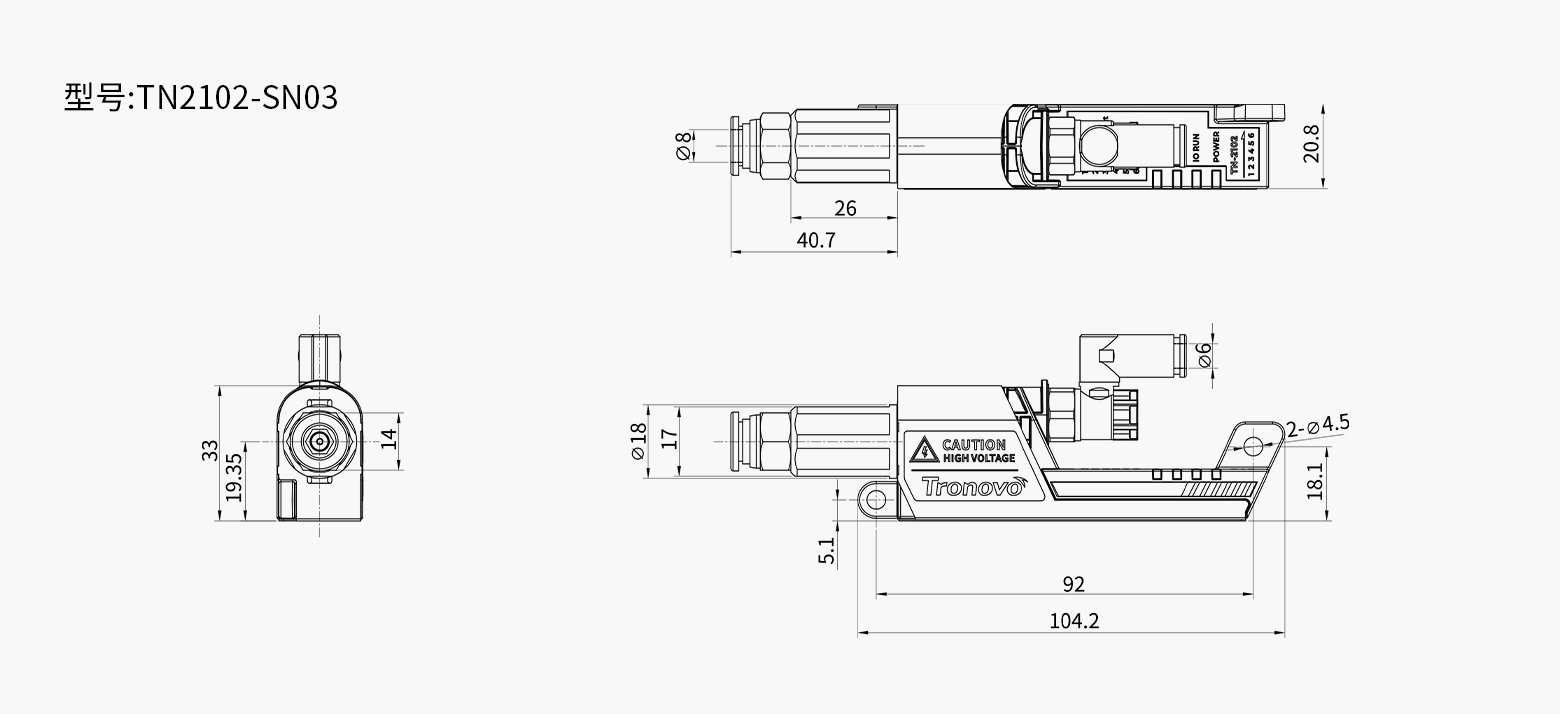

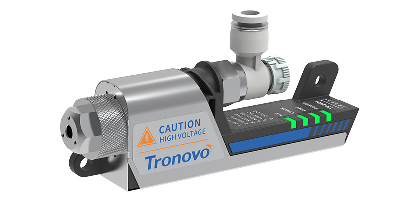

| Universal nozzle |

MODEL:DN251-SN20 |  MODEL:TN-SN20 | Metal | Automatic ion balancing system, LED display maintenance alarm function

I/0 wiring signal (support PLC control), recommended by the automation industry |

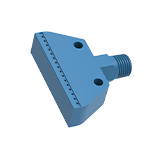

| Rotate the fixing bracket |

|  MODEL:TN-RB01 | SUS 304 | The ionic nozzle body is fixed and installed |