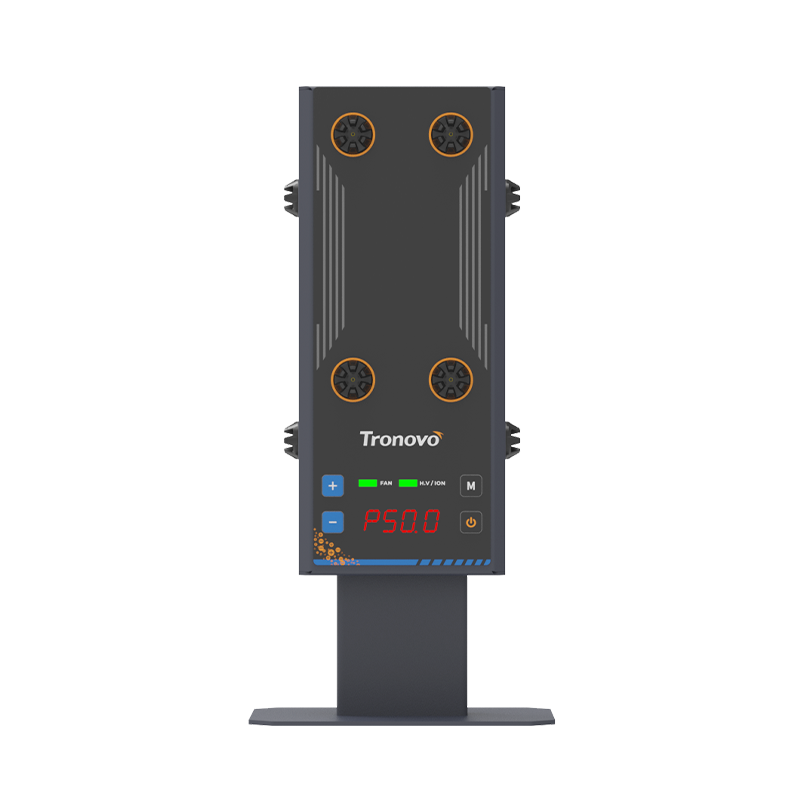

| Model | DS933/DS933P |

| Removal method | Compound pulse DC method: Compound pulse DC method |

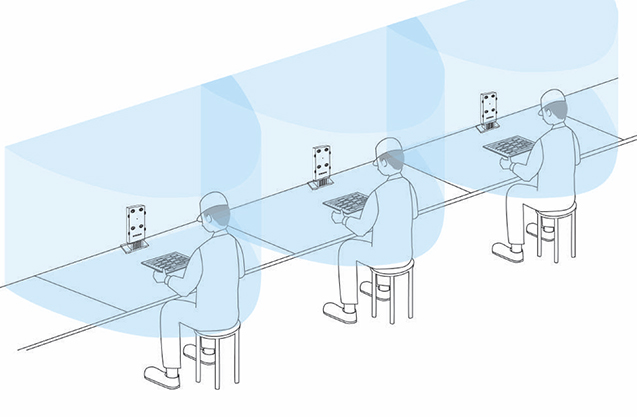

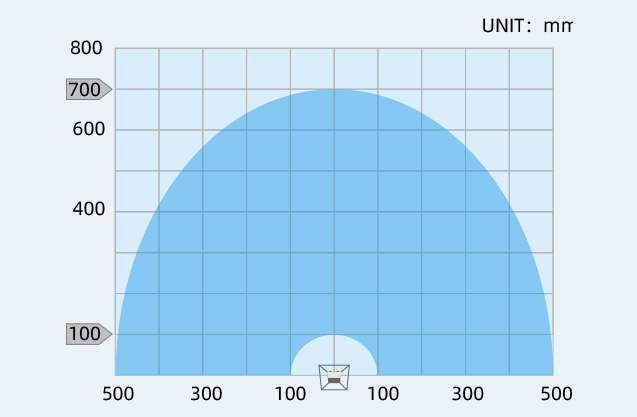

| Removal of static electricity effective range | 1000/100~700 |

| Electrical removal performance | Approx. 1.5 sec. (20pF, 200mm, no wind, measured in the center) |

| Ion balance control mode | The response control method is controlled by the ion balance sensor |

| ionic balance | ± 100V or less |

| Number of discharge pins | Material: titanium products/8 pieces |

| Discharge needle cleaning method | The attached brush sweeps the needles |

| Discharge needle life | Approx. 24,000 hours (needle exchangeable) |

| Electrical removal performance life | Approx. 50.000/hour |

| The amount of ozone produced | 0.05 ppm or less (center, 200 mm in front) |

| Expressed in action | Green (power) LED light, blue (ion) LED light |

| Light-emitting diodes | Yellow (clean) LED lights up |

| The alarm indicates the LED | Red ERROR) LED lights up |

| Alert output | Red LED gram pad seeds |

| Explosion-proof/non-explosion-proof distinction | Do not use in explosion-proof areas for non-explosion-proof situations |

| Electricity Consumption (W) | 4.5 |

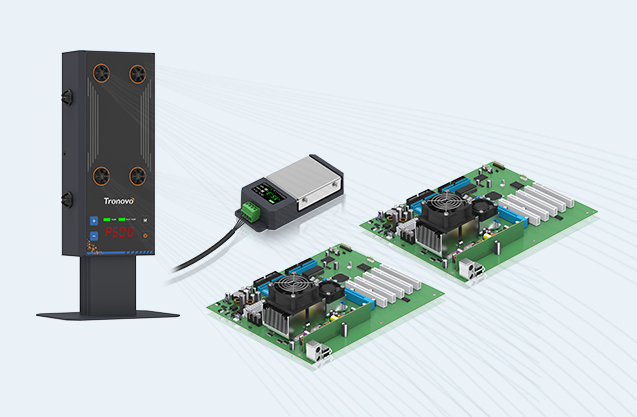

| power supply | AC Power Supply (Input: AC100~240V±10%, 50/60Hz Output: DC24V) |

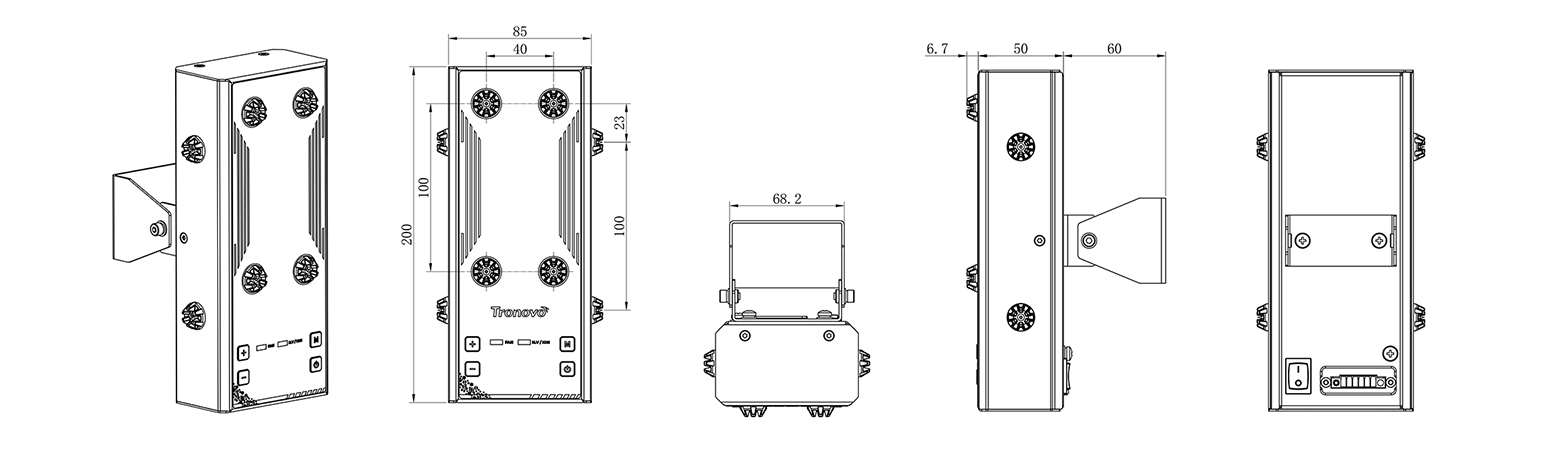

| Dimensions | 102*134*50 |

| Remove protrusions | 102*134*50 |

| Mass (g) | 350 |

| Operating temperature, humidity | 0~40C.35~65%RH |

| fittings | AC connector, grounding wire, brush |