The innovative pulsed high-voltage corona discharge technology revolutionarily solves the ion self-neutralization problem of traditional static eliminators. With a pulse cycle extended by 10-50 times and an original adjustable pulse cycle design, it achieves precise control over the electrostatic neutralization process: ensuring ion transmission at long distances and enhancing neutralization efficiency at close distances. This technological breakthrough enables fanless long-distance static elimination, perfectly fitting high-demand environments sensitive to airflow such as dust-free workshops and precision electronics manufacturing. It meets the windless operation requirements of special processes and is an ideal choice for high-end manufacturing.

Product feature:

・Wide-area static elimination, with a wide effective range

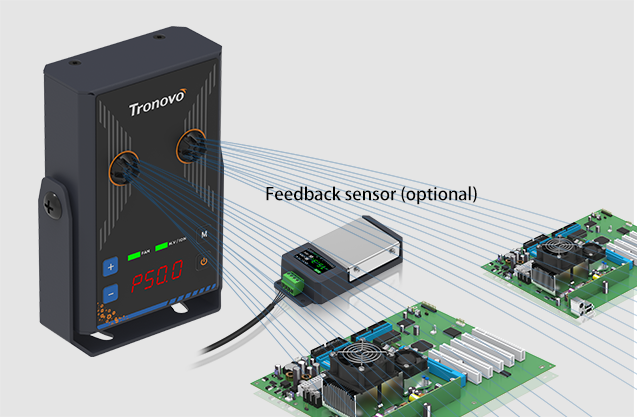

・Ion balance: manual/feedback dual control

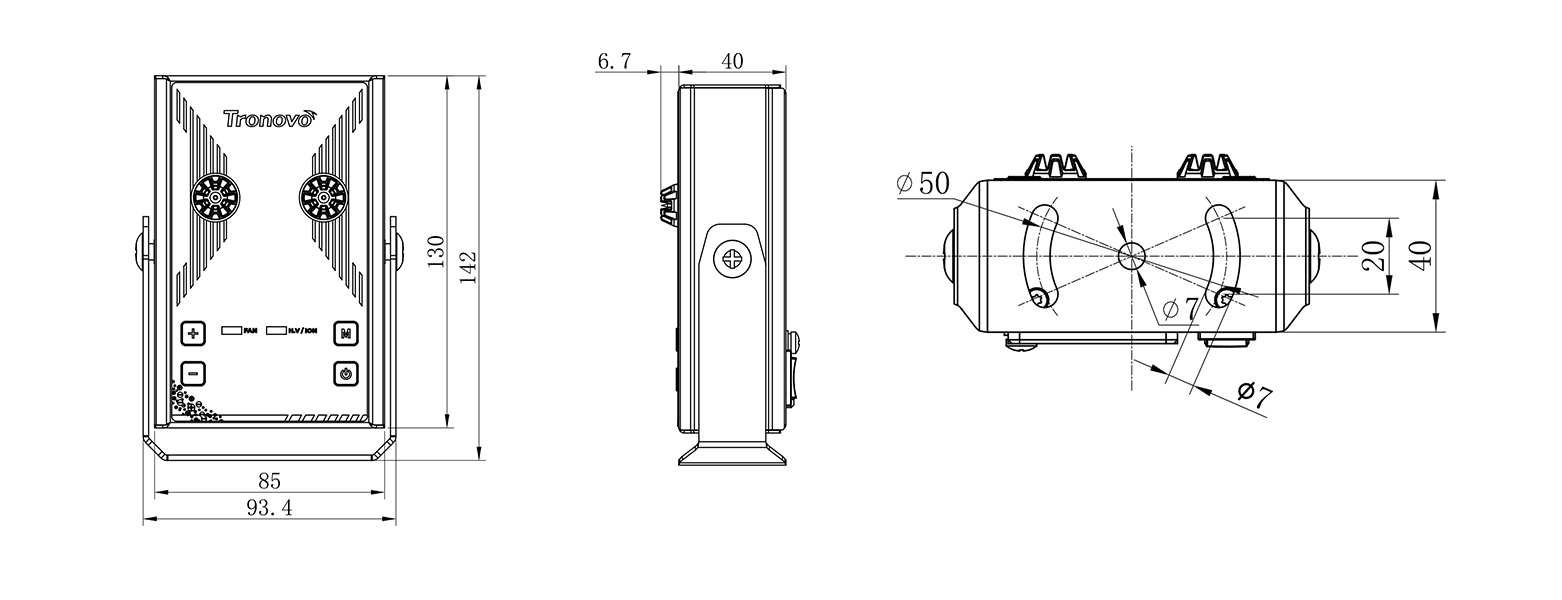

・Desktop design, compact and portable

・Excellent performance, precise ion balance

・No leakage design, stable and trouble-free

・The maintenance is simple, reducing costs

・Suitable for dusty environments, with strong adaptability

・Can be embedded inside the machine for flexible installation

・No conductive wristband required