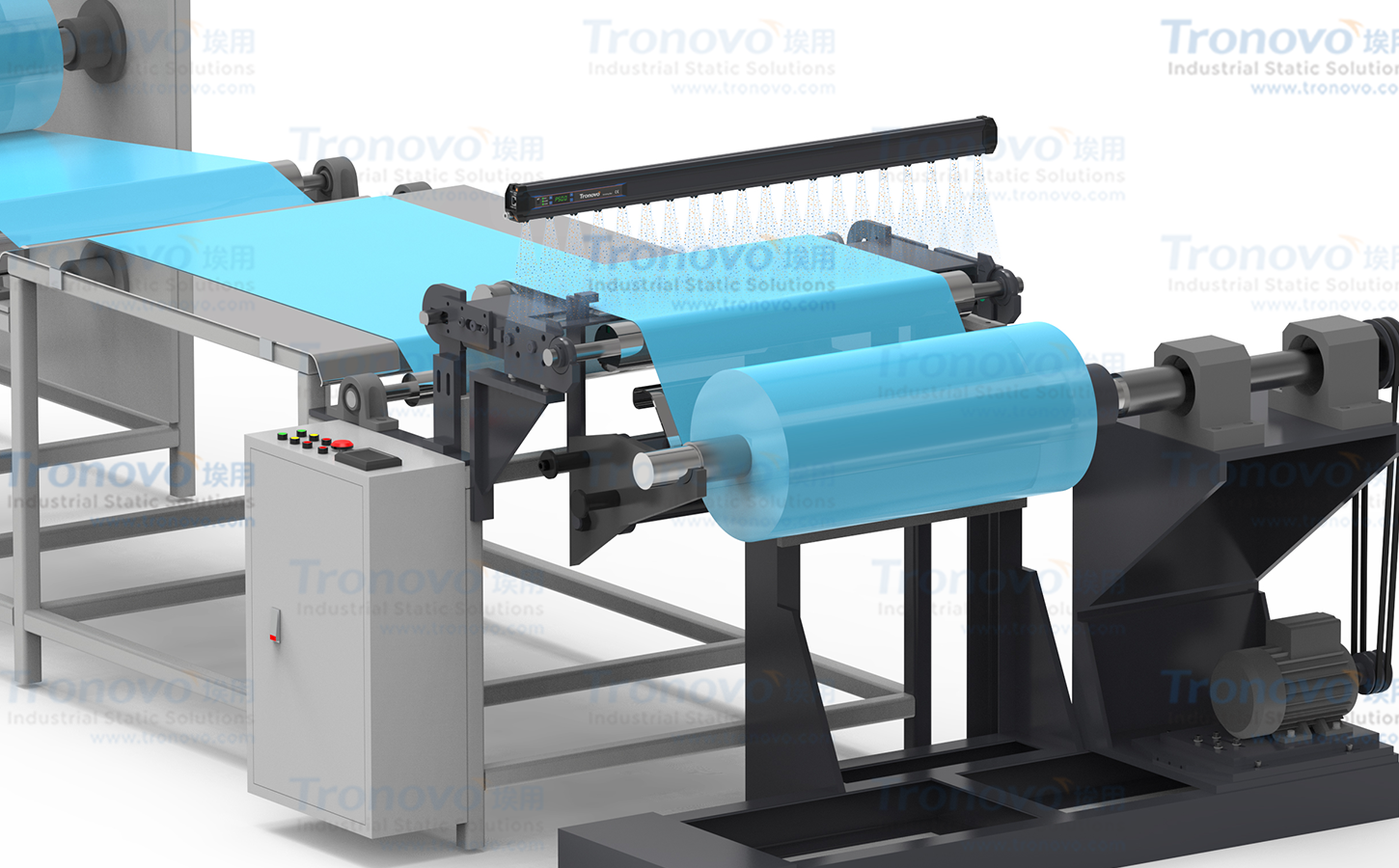

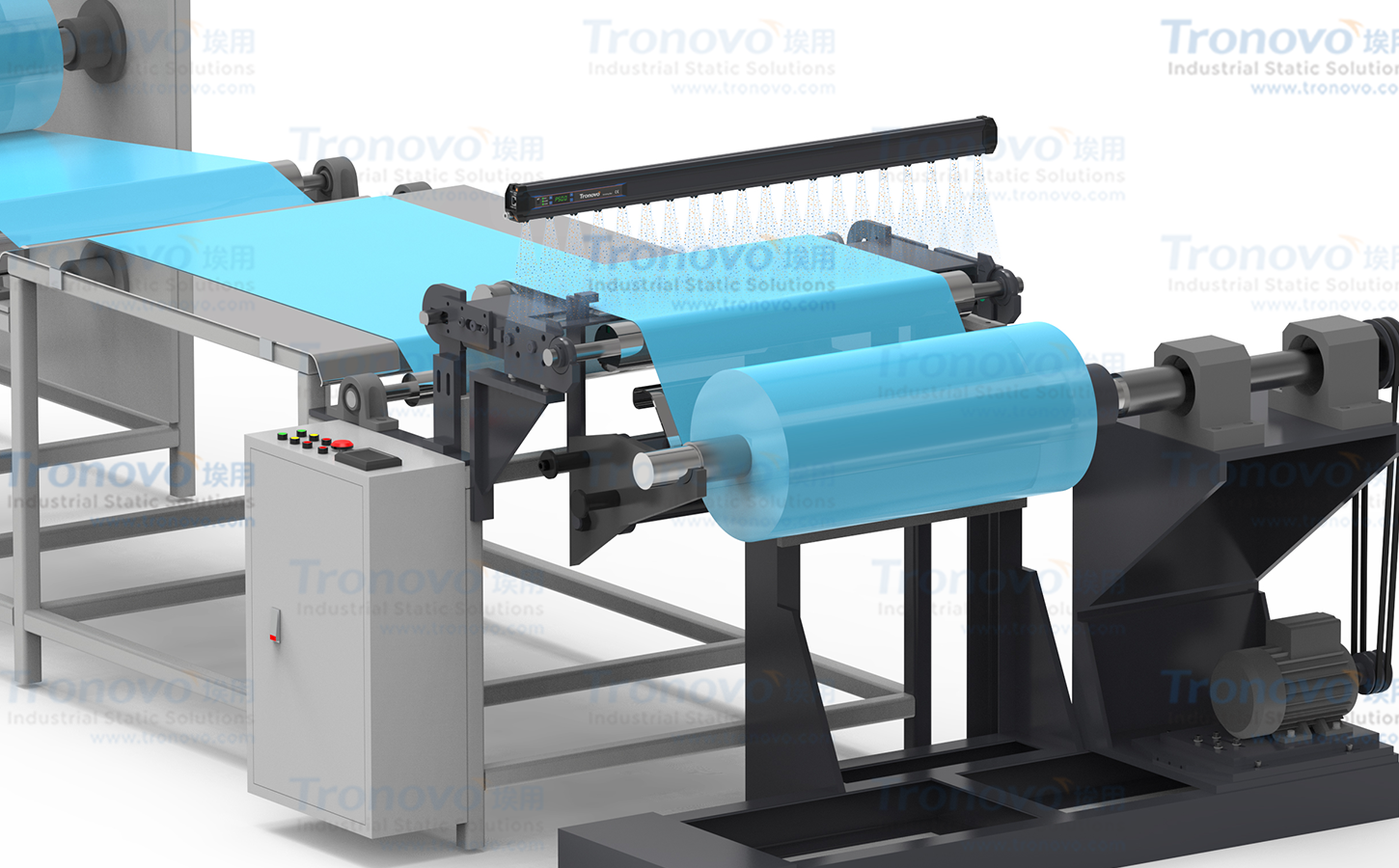

Application case of pulse ion rod in static electricity removal at the winding position of rewinding machine

Problem description:

In the production process of coil materials, the winding position of the rewinder is a high-risk area for electrostatic issues. When materials are wound at high speed, high-intensity static electricity is easily generated due to friction, peeling, and changes in winding tension, leading to defects such as dust adsorption on the surface of the finished coil, curling, warping, and delamination, which seriously affect the appearance quality and subsequent processing performance of the product. Traditional dust removal methods are difficult to effectively eliminate the accumulation of static electricity during winding, becoming a key bottleneck in improving the quality and production efficiency of coil materials.

Solution

A certain coil material production enterprise has introduced a pulsed AC ionizing air bar at the winding section of the rewinder to implement precise electrostatic control. The ionizing air bar is directly installed above the front side of the winding roller, releasing a large amount of positive and negative ions through pulsed AC mode, rapidly neutralizing the electrostatic charges on the surface of the coil material and fundamentally eliminating the electrostatic attraction force.

Core advantages:

The pulse ionizing bar is characterized by fast response, wide coverage, and high stability, making it particularly suitable for high-speed winding conditions. Its installation position has been optimized through simulation and actual measurement to ensure that the ionizing airflow fully covers the entire width of the coil material, leaving no treatment dead zones.